Hi i am following this tutorial:

using the same wiring and so

although i added a led to indicate the hall sensor being triggered and an hall sensor

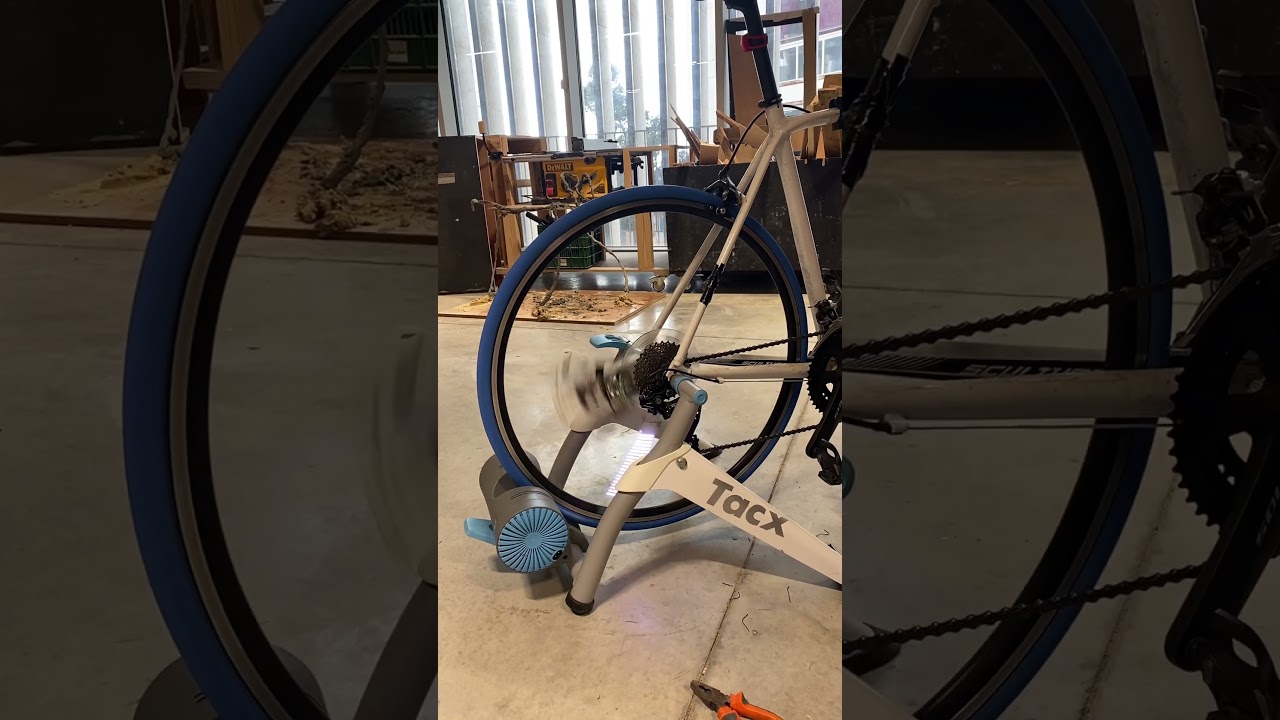

the reason is for mw to be able to make this device interactive and in the end ride on a trainer on a show in my art school

hope this code thingy worked

so, what is the problem? everything seems to be logical dn working.. but yet i am bothered by that the time it takes to "show" an image that is 100 pixel wide is 1 second!

i think there is something i am missing.. maybe there is a limit of how long a picture can be for this work..

maybe my code is slow..

this is the part i am asking for help

because in 27kmh the bike is around 7.5m/s and that is a revolution in 200 milliseconds ( if i got this right ) thanks a lot and sorry if the topic/forum is not tight, will fix and edit if needed

thanks again

the code is added:

// SPDX-FileCopyrightText: 2019 Phillip Burgess for Adafruit Industries

//

// SPDX-License-Identifier: MIT

/*-----------------------------------------------------------------------

POV LED bike wheel sketch. Uses the following Adafruit parts:

- Pro Trinket 5V (www.adafruit.com/product/2000)

(NOT Trinket or 3V Pro Trinket)

- Waterproof 3xAA battery holder with on/off switch (#771)

- 144 LED/m DotStar strip (#2328 or #2329) ONE is enough for

both sides of one bike wheel

- Tactile switch button (#1119) (optional)

Needs Adafruit_DotStar library: github.com/adafruit/Adafruit_DotStar

Full instructions: https://learn.adafruit.com/bike-wheel-pov-display

This project is based on Phil B's Genesis Poi:

learn.adafruit.com/genesis-poi-dotstar-led-persistence-of-vision-poi

and has been adapted to the Pro Trinket to accomodate more and larger

images than Trinket.

Adafruit invests time and resources providing this open source code,

please support Adafruit and open-source hardware by purchasing

products from Adafruit!

Written by Phil Burgess / Paint Your Dragon for Adafruit Industries.

MIT license, all text above must be included in any redistribution.

See 'COPYING' file for additional notes.

------------------------------------------------------------------------*/

#include <Arduino.h>

#include <Adafruit_DotStar.h>

#include <avr/power.h>

#include <avr/sleep.h>

#include <avr/interrupt.h>

#include <SPI.h> // Enable this line on Pro Trinket

#ifdef __AVR_ATtiny85__

typedef uint8_t line_t; // Max 255 lines/image on Trinket

#else

typedef uint16_t line_t; // Bigger images OK on other boards

#endif

// CONFIGURABLE STUFF ------------------------------------------------------

#include "graphics.h" // Graphics data is contained in this header file.

// It's generated using the 'convert.py' Python script. Various image

// formats are supported, trading off color fidelity for PROGMEM space

// (particularly limited on Trinket). Handles 1-, 4- and 8-bit-per-pixel

// palette-based images, plus 24-bit truecolor. 1- and 4-bit palettes can

// be altered in RAM while running to provide additional colors, but be

// mindful of peak & average current draw if you do that! Power limiting

// is normally done in convert.py (keeps this code relatively small & fast).

// 1/4/8/24 were chosen because the AVR can handle these operations fairly

// easily (have idea for handing arbitrary bit depth w/328P, but this margin

// is too narrow to contain).

// Ideally you use hardware SPI as it's much faster, though limited to

// specific pins. If you really need to bitbang DotStar data & clock on

// different pins, optionally define those here:

#define LED_DATA_PIN 11

#define LED_CLOCK_PIN 13

#define HALL_SENSOR_PIN 3

#define LED_HALLPPIN 12

volatile bool ledState = false;

// Select from multiple images using tactile button (#1489) between pin and

// ground. Requires suitably-built graphics.h file w/more than one image.

//#define SELECT_PIN 3

// Optional feature -- not enabled here, no space -- a vibration switch

// (aligned perpendicular to leash) is used as a poor man's accelerometer.

// Poi then lights only when moving, saving some power. The 'fast'

// vibration switch is VERY sensitive and will trigger at the slightest

// bump, while the 'medium' switch requires a certain spin rate which may

// not trigger if you're doing mellow spins. Neither is perfect. To leave

// that out and simply have the poi run always-on, comment out this line:

//#define MOTION_PIN 2

// Another optional feature not enable due to physical size -- powering down

// DotStars when idle conserves more battery. Use a PNP transistor (e.g.

// 2N2907) (w/220 Ohm resistor to base) as a 'high side' switch to DotStar

// +V. DON'T do this NPN/low-side, may damage strip. MOTION_PIN must also

// be defined to use this (pointless without).

//#define POWER_PIN 4

#define SLEEP_TIME 2000 // Not-spinning time before sleep, in milliseconds

// Empty and full thresholds (millivolts) used for battery level display:

#define BATT_MIN_MV 3350 // Some headroom over battery cutoff near 2.9V

#define BATT_MAX_MV 4000 // And little below fresh-charged battery near 4.1V

// These figures are based on LiPoly cell and will need to be tweaked for

// 3X NiMH or alkaline batteries!

boolean autoCycle = true; // Set to true to cycle images by default

#define CYCLE_TIME 30000 // Time, in seconds, between auto-cycle images

boolean startedImage = false; // Flag indicating if an image has started

boolean measuredImage = false; // Flag indicating if an image has been measured

uint32_t startedImageTime, finishedImage, duration, startTime, timeItTakesImage, delaytime = 0;

uint32_t s = millis();

// -------------------------------------------------------------------------

#if defined(LED_DATA_PIN) && defined(LED_CLOCK_PIN)

// Older DotStar LEDs use GBR order. If colors are wrong, edit here.

Adafruit_DotStar strip = Adafruit_DotStar(NUM_LEDS,

LED_DATA_PIN, LED_CLOCK_PIN, DOTSTAR_BRG);

#else

Adafruit_DotStar strip = Adafruit_DotStar(NUM_LEDS, DOTSTAR_BGR);

#endif

void imageInit(void);

uint16_t readVoltage(void);

#ifdef MOTION_PIN

void sleep(void);

#endif

void setup() {

Serial.begin(9600);

pinMode(HALL_SENSOR_PIN, INPUT_PULLUP);

attachInterrupt(digitalPinToInterrupt(HALL_SENSOR_PIN), isr, FALLING);

#if defined(__AVR_ATtiny85__) && (F_CPU == 16000000L)

clock_prescale_set(clock_div_1); // Enable 16 MHz on Trinket

#endif

#ifdef POWER_PIN

pinMode(POWER_PIN, OUTPUT);

digitalWrite(POWER_PIN, LOW); // Power-on LED strip

#endif

strip.begin(); // Allocate DotStar buffer, init SPI

strip.clear(); // Make sure strip is clear

strip.show(); // before measuring battery

// Display battery level bargraph on startup. It's just a vague estimate

// based on cell voltage (drops with discharge) but doesn't handle curve.

uint16_t mV = readVoltage();

uint8_t lvl = (mV >= BATT_MAX_MV) ? NUM_LEDS : // Full (or nearly)

(mV <= BATT_MIN_MV) ? 1 : // Drained

1 + ((mV - BATT_MIN_MV) * NUM_LEDS + (NUM_LEDS / 2)) /

(BATT_MAX_MV - BATT_MIN_MV + 1); // # LEDs lit (1-NUM_LEDS)

for (uint8_t i = 0; i < lvl; i++) { // Each LED to batt level...

uint8_t g = (i * 5 + 2) / NUM_LEDS; // Red to green

strip.setPixelColor(i, 4 - g, g, 0);

strip.show(); // Animate a bit

delay(250 / NUM_LEDS);

}

delay(1500); // Hold last state a moment

strip.clear(); // Then clear strip

strip.show();

imageInit(); // Initialize pointers for default image

#ifdef SELECT_PIN

pinMode(SELECT_PIN, INPUT_PULLUP);

#endif

#ifdef MOTION_PIN

pinMode(MOTION_PIN, INPUT_PULLUP);

sleep(); // Sleep until motion detected

#endif

}

// GLOBAL STATE STUFF ------------------------------------------------------

uint32_t lastImageTime = 0L; // Time of last image change

#ifdef MOTION_PIN

uint32_t prev = 0L; // Used for sleep timing

#endif

uint8_t imageNumber = 0, // Current image being displayed

imageType, // Image type: PALETTE[1,4,8] or TRUECOLOR

*imagePalette, // -> palette data in PROGMEM

*imagePixels, // -> pixel data in PROGMEM

palette[16][3]; // RAM-based color table for 1- or 4-bit images

line_t imageLines, // Number of lines in active image

imageLine; // Current line number in image

#ifdef SELECT_PIN

uint8_t debounce = 0; // Debounce counter for image select pin

#endif

void imageInit() { // Initialize global image state for current imageNumber

imageType = pgm_read_byte(&images[imageNumber].type);

#ifdef __AVR_ATtiny85__

imageLines = pgm_read_byte(&images[imageNumber].lines);

#else

imageLines = pgm_read_word(&images[imageNumber].lines);

#endif

imageLine = 0;

imagePalette = (uint8_t *)pgm_read_word(&images[imageNumber].palette);

imagePixels = (uint8_t *)pgm_read_word(&images[imageNumber].pixels);

// 1- and 4-bit images have their color palette loaded into RAM both for

// faster access and to allow dynamic color changing. Not done w/8-bit

// because that would require inordinate RAM (328P could handle it, but

// I'd rather keep the RAM free for other features in the future).

if (imageType == PALETTE1) memcpy_P(palette, imagePalette, 2 * 3);

else if (imageType == PALETTE4) memcpy_P(palette, imagePalette, 16 * 3);

lastImageTime = millis(); // Save time of image init for next auto-cycle

}

void nextImage(void) {

if (++imageNumber >= NUM_IMAGES) imageNumber = 0;

imageInit();

}

void isr() {

uint32_t now = millis();

duration = now - startTime;

startTime = now;

ledState = !ledState; // Toggle LED state

digitalWrite(LED_HALLPPIN, ledState);

}

// MAIN LOOP ---------------------------------------------------------------

void loop() {

uint32_t t = millis(); // Current time, milliseconds

#ifdef MOTION_PIN

// Tried to do this with watchdog timer but encountered gas pains, so...

if (!digitalRead(MOTION_PIN)) { // Vibration switch pulled down?

prev = t; // Yes, reset timer

} else if ((t - prev) > SLEEP_TIME) { // No, SLEEP_TIME elapsed w/no switch?

sleep(); // Power down

prev = t; // Reset timer on wake

}

#endif

if (autoCycle) {

if ((t - lastImageTime) >= (CYCLE_TIME * 1000L)) nextImage();

// CPU clocks vary slightly; multiple poi won't stay in perfect sync.

// Keep this in mind when using auto-cycle mode, you may want to cull

// the image selection to avoid unintentional regrettable combinations.

}

#ifdef SELECT_PIN

if (digitalRead(SELECT_PIN)) { // Image select?

debounce = 0; // Not pressed -- reset counter

} else { // Pressed...

if (++debounce >= 25) { // Debounce input

nextImage(); // Switch to next image

while (!digitalRead(SELECT_PIN)); // Wait for release

// If held 1+ sec, toggle auto-cycle mode on/off

if ((millis() - t) >= 1000L) autoCycle = !autoCycle;

debounce = 0;

}

}

#endif

// Transfer one scanline from pixel data to LED strip:

if (!startedImage)

{

startedImageTime = millis();

startedImage = true;

}

// If you're really pressed for graphics space and need just a few extra

// scanlines, and know for a fact you won't be using certain image modes,

// you can comment out the corresponding blocks below. e.g. PALETTE8 and

// TRUECOLOR are somewhat impractical on Trinket, and commenting them out

// can free up nearly 200 bytes of extra image storage.

switch (imageType) {

case PALETTE1: { // 1-bit (2 color) palette-based image

uint8_t pixelNum = 0, byteNum, bitNum, pixels, idx,

*ptr = (uint8_t *)&imagePixels[imageLine * NUM_LEDS / 8];

for (byteNum = NUM_LEDS / 8; byteNum--; ) { // Always padded to next byte

pixels = pgm_read_byte(ptr++); // 8 pixels of data (pixel 0 = LSB)

for (bitNum = 8; bitNum--; pixels >>= 1) {

idx = pixels & 1; // Color table index for pixel (0 or 1)

strip.setPixelColor(pixelNum++,

palette[idx][0], palette[idx][1], palette[idx][2]);

}

}

break;

}

case PALETTE4: { // 4-bit (16 color) palette-based image

uint8_t pixelNum, p1, p2,

*ptr = (uint8_t *)&imagePixels[imageLine * NUM_LEDS / 2];

for (pixelNum = 0; pixelNum < NUM_LEDS; ) {

p2 = pgm_read_byte(ptr++); // Data for two pixels...

p1 = p2 >> 4; // Shift down 4 bits for first pixel

p2 &= 0x0F; // Mask out low 4 bits for second pixel

strip.setPixelColor(pixelNum++,

palette[p1][0], palette[p1][1], palette[p1][2]);

strip.setPixelColor(pixelNum++,

palette[p2][0], palette[p2][1], palette[p2][2]);

}

break;

}

case PALETTE8: { // 8-bit (256 color) PROGMEM-palette-based image

uint16_t o;

uint8_t pixelNum,

*ptr = (uint8_t *)&imagePixels[imageLine * NUM_LEDS];

for (pixelNum = 0; pixelNum < NUM_LEDS; pixelNum++) {

o = pgm_read_byte(ptr++) * 3; // Offset into imagePalette

strip.setPixelColor(pixelNum,

pgm_read_byte(&imagePalette[o]),

pgm_read_byte(&imagePalette[o + 1]),

pgm_read_byte(&imagePalette[o + 2]));

}

break;

}

case TRUECOLOR: { // 24-bit ('truecolor') image (no palette)

uint8_t pixelNum, r, g, b,

*ptr = (uint8_t *)&imagePixels[imageLine * NUM_LEDS * 3];

for (pixelNum = 0; pixelNum < NUM_LEDS; pixelNum++) {

r = pgm_read_byte(ptr++);

g = pgm_read_byte(ptr++);

b = pgm_read_byte(ptr++);

strip.setPixelColor(pixelNum, r, g, b);

}

break;

}

}

strip.show(); // Refresh LEDs

#if !defined(LED_DATA_PIN) && !defined(LED_CLOCK_PIN)

delayMicroseconds(900); // Because hardware SPI is fast

#endif

Serial.println(millis());

// Check if all lines of the image have been displayed

if (++imageLine >= imageLines) {

// Record the time it took to display the entire image

if (startedImage && !measuredImage) {

finishedImage = millis();

timeItTakesImage = finishedImage - startedImageTime; // Corrected calculation

measuredImage = true;

Serial.print("the time it takes to image: ");

Serial.println(timeItTakesImage);

}

// Reset line counter for next image

imageLine = 0;

}

if (timeItTakesImage > 0 && duration > 0) {

// Toggle the LED pin to mark the end of the image display

// Calculate the delay time while handling overflow

uint32_t timeDifference = 0;

if (duration >= timeItTakesImage) {

timeDifference = duration - timeItTakesImage;

}

delaytime = timeDifference / imageLines;

}

if(delaytime>0){

delay(delaytime);

}

}

// POWER-SAVING STUFF -- Relentlessly non-portable -------------------------

#ifdef MOTION_PIN

void sleep() {

// Turn off LEDs...

strip.clear(); // Issue '0' data

strip.show();

#ifdef POWER_PIN

digitalWrite(POWER_PIN, HIGH); // Cut power

#if !defined(LED_DATA_PIN) && !defined(LED_CLOCK_PIN)

#ifdef __AVR_ATtiny85__

pinMode(1, INPUT); // Set SPI data & clock to inputs else

pinMode(2, INPUT); // DotStars power parasitically, jerks.

#else

pinMode(11, INPUT);

pinMode(13, INPUT);

#endif // ATtiny

#endif // Data/clock/pins

#endif // POWER_PIN

power_all_disable(); // Peripherals ALL OFF, best sleep-state battery use

// Enable pin-change interrupt on motion pin

#ifdef __AVR_ATtiny85__

PCMSK = _BV(MOTION_PIN); // Pin mask

GIMSK = _BV(PCIE); // Interrupt enable

#else

volatile uint8_t *p = portInputRegister(digitalPinToPort(MOTION_PIN));

if (p == &PIND) { // Pins 0-7 = PCINT16-23

PCMSK2 = _BV(MOTION_PIN);

PCICR = _BV(PCIE2);

} else if (p == &PINB) { // Pins 8-13 = PCINT0-5

PCMSK0 = _BV(MOTION_PIN - 8);

PCICR = _BV(PCIE0);

} else if (p == &PINC) { // Pins 14-20 = PCINT8-14

PCMSK1 = _BV(MOTION_PIN - 14);

PCICR = _BV(PCIE1);

}

#endif

// If select pin is enabled, that wakes too!

#ifdef SELECT_PIN

debounce = 0;

#ifdef __AVR_ATtiny85__

PCMSK |= _BV(SELECT_PIN); // Add'l pin mask

#else

volatile uint8_t *p = portInputRegister(digitalPinToPort(SELECT_PIN));

if (p == &PIND) { // Pins 0-7 = PCINT16-23

PCMSK2 = _BV(SELECT_PIN);

PCICR = _BV(PCIE2);

} else if (p == &PINB) { // Pins 8-13 = PCINT0-5

PCMSK0 = _BV(SELECT_PIN - 8);

PCICR = _BV(PCIE0);

} else if (p == &PINC) { // Pins 14-20 = PCINT8-14

PCMSK1 = _BV(SELECT_PIN - 14);

PCICR = _BV(PCIE1);

}

#endif // ATtiny

#endif // SELECT_PIN

set_sleep_mode(SLEEP_MODE_PWR_DOWN); // Deepest sleep mode

sleep_enable();

interrupts();

sleep_mode(); // Power down

// Resumes here on wake

// Clear pin change settings so interrupt won't fire again

#ifdef __AVR_ATtiny85__

GIMSK = PCMSK = 0;

#else

PCICR = PCMSK0 = PCMSK1 = PCMSK2 = 0;

#endif

power_timer0_enable(); // Used by millis()

#if !defined(LED_DATA_PIN) && !defined(LED_CLOCK_PIN)

#ifdef __AVR_ATtiny85__

pinMode(1, OUTPUT); // Re-enable SPI pins

pinMode(2, OUTPUT);

power_usi_enable(); // Used by DotStar

#else

pinMode(11, OUTPUT); // Re-enable SPI pins

pinMode(13, OUTPUT);

power_spi_enable(); // Used by DotStar

#endif // ATtiny

#endif // Data/clock pins

#ifdef POWER_PIN

digitalWrite(POWER_PIN, LOW); // Power-up LEDs

#endif

prev = millis(); // Save wake time

}

EMPTY_INTERRUPT(PCINT0_vect); // Pin change (does nothing, but required)

#ifndef __AVR_ATtiny85__

ISR(PCINT1_vect, ISR_ALIASOF(PCINT0_vect));

ISR(PCINT2_vect, ISR_ALIASOF(PCINT0_vect));

#endif

#endif // MOTION_PIN

// Battery monitoring idea adapted from JeeLabs article:

// jeelabs.org/2012/05/04/measuring-vcc-via-the-bandgap/

// Code from Adafruit TimeSquare project, added Trinket support.

// In a pinch, the poi code can work on a 3V Trinket, but the battery

// monitor will not work correctly (due to the 3.3V regulator), so

// maybe just comment out any reference to this code in that case.

uint16_t readVoltage() {

int i, prev;

uint8_t count;

uint16_t mV;

// Select AVcc voltage reference + Bandgap (1.8V) input

#ifdef __AVR_ATtiny85__

ADMUX = _BV(MUX3) | _BV(MUX2);

#else

ADMUX = _BV(REFS0) |

_BV(MUX3) | _BV(MUX2) | _BV(MUX1);

#endif

ADCSRA = _BV(ADEN) | // Enable ADC

_BV(ADPS2) | _BV(ADPS1) | _BV(ADPS0); // 1/128 prescaler (125 KHz)

// Datasheet notes that the first bandgap reading is usually garbage as

// voltages are stabilizing. It practice, it seems to take a bit longer

// than that. Tried various delays, but still inconsistent and kludgey.

// Instead, repeated readings are taken until four concurrent readings

// stabilize within 10 mV.

for (prev = 9999, count = 0; count < 4; ) {

for (ADCSRA |= _BV(ADSC); ADCSRA & _BV(ADSC); ); // Start, await ADC conv.

i = ADC; // Result

mV = i ? (1100L * 1023 / i) : 0; // Scale to millivolts

if (abs((int)mV - prev) <= 10) count++; // +1 stable reading

else count = 0; // too much change, start over

prev = mV;

}

ADCSRA = 0; // ADC off

return mV;

}```

type or paste code here