My project uses 13 servos. I want to use the Adafruit i2c PCA 9685 board to connect the servos (for ease of installation wiring)

I am using an Ardunio Mega board to handle the data.

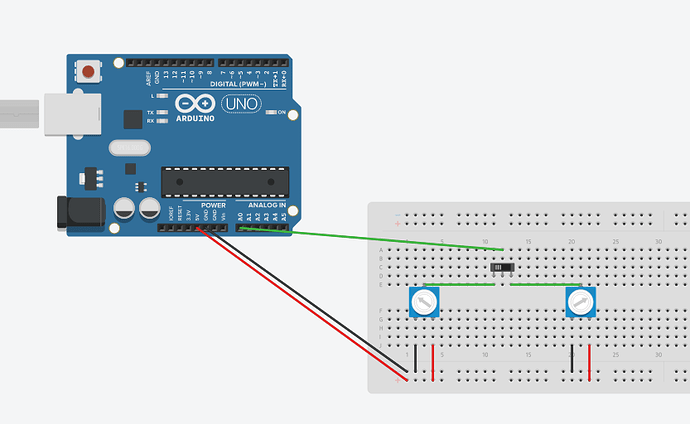

Pins 0 - 12 are each connected to the common of a toggle switch, which in turn is connected either side to a preset pot with the wiper of each pot connected to one side of a switch.

The center (common) of the switch goes into the analogue input of the Mega. Toggling one way (or the other) provides a user defined voltage to the analogue pin (depends on the pot setting - its configured as a voltage divider with the wiper position giving the value to the Mega)

The Mega / Adafruit i2c PCA 9685 works fine when I run a test program which sweeps the servos through their full arc. (ie the comms and servos are working ok)

When I use the code below, the program executes the code servos 0 -3 work and go to their set position, but then all servos start chattering (move through perhaps 5 deg arc at random)

I can use 4 servos without problem - as soon as I plug the others in its an issue.

I have checked the current being drawn from the power supply and the combination draws 870ma at peak.

What am I doing wrong?

#include "HCPCA9685.h" // Include the HCPCA9685 library created by Andrew Davies

#define I2CAdd 0x40 // Default address of the PCA9685 Module

#define PotA A0 // Pot pin connected to A0

#define PotB A1 // Pot pin connected to A1

#define PotC A2 // Pot pin connected to A2

#define PotD A3 // Pot pin connected to A3

#define PotE A4 // Pot pin connected to A4

#define PotF A5 // Pot pin connected to A5

#define PotG A6 // Pot pin connected to A6

#define PotH A7 // Pot pin connected to A7

#define PotI A8 // Pot pin connected to A8

#define PotJ A9 // Pot pin connected to A9

#define PotK A10 // Pot pin connected to A10

#define PotL A11 // Pot pin connected to A11

#define PotM A12 // Pot pin connected to A12

// Used to store the mapping of the Pot values

int ServoA;

int ServoB;

int ServoC;

int ServoD;

int ServoE;

int ServoF;

int ServoG;

int ServoH;

int ServoI;

int ServoJ;

int ServoK;

int ServoL;

int ServoM;

HCPCA9685 HCPCA9685(I2CAdd); // Define Library to use I2C communication

void setup()

{

HCPCA9685.Init(SERVO_MODE); // Set to Servo Mode

HCPCA9685.Sleep(false); // Wake up PCA9685 module

}

void loop()

{

int val1A = analogRead(PotA); // Read current value of PotA

int val1B = analogRead(PotB); // Read current value of PotB

int val1C = analogRead(PotC); // Read current value of PotC

int val1D = analogRead(PotD); // Read current value of PotD

int val1E = analogRead(PotE); // Read current value of PotE

int val1F = analogRead(PotF); // Read current value of PotF

int val1G = analogRead(PotG); // Read current value of PotG

int val1H = analogRead(PotH); // Read current value of PotH

int val1I = analogRead(PotI); // Read current value of PotI

int val1J = analogRead(PotJ); // Read current value of PotJ

int val1K = analogRead(PotK); // Read current value of PotK

int val1L = analogRead(PotL); // Read current value of PotL

int val1M = analogRead(PotM); // Read current value of PotM

// Map Pot values to servo Min and Max position

ServoA = map(val1A, 0, 1023, 10, 420); // Used to move Servo 0

ServoB = map(val1B, 0, 1023, 10, 420); // Used to move Servo 1

ServoC = map(val1C, 0, 1023, 10, 420); // Used to move Servo 2

ServoD = map(val1D, 0, 1023, 10, 420); // Used to move Servo 3

ServoE = map(val1E, 0, 1023, 10, 420); // Used to move Servo 4

ServoF = map(val1F, 0, 1023, 10, 420); // Used to move Servo 5

ServoG = map(val1G, 0, 1023, 10, 420); // Used to move Servo 6

ServoD = map(val1H, 0, 1023, 10, 420); // Used to move Servo 7

ServoI = map(val1I, 0, 1023, 10, 420); // Used to move Servo 8

ServoJ = map(val1J, 0, 1023, 10, 420); // Used to move Servo 9

ServoK = map(val1K, 0, 1023, 10, 420); // Used to move Servo 10

ServoL = map(val1L, 0, 1023, 10, 420); // Used to move Servo 11

ServoM = map(val1M, 0, 1023, 10, 420); // Used to move Servo 12

// Move Servos to read postion from pot

HCPCA9685.Servo(0, ServoA); // Move Servo 0

HCPCA9685.Servo(1, ServoB); // Move Servo 1

HCPCA9685.Servo(2, ServoC); // Move Servo 2

HCPCA9685.Servo(3, ServoD); // Move Servo 3

HCPCA9685.Servo(4, ServoE); // Move Servo 4

HCPCA9685.Servo(5, ServoF); // Move Servo 5

HCPCA9685.Servo(6, ServoG); // Move Servo 6

HCPCA9685.Servo(7, ServoH); // Move Servo 7

HCPCA9685.Servo(8, ServoI); // Move Servo 8

HCPCA9685.Servo(9, ServoJ); // Move Servo 9

HCPCA9685.Servo(10, ServoK); // Move Servo 10

HCPCA9685.Servo(11, ServoL); // Move Servo 11

HCPCA9685.Servo(12, ServoM); // Move Servo 12- Turn Table

delay(100);

}

}