First of all, thank you so much for the continuous help. It means a lot to an absolute beginner like myself who barely knows what "PCB" even means!

Yup, totally forgot to rename them correctly after Copy/Pasting

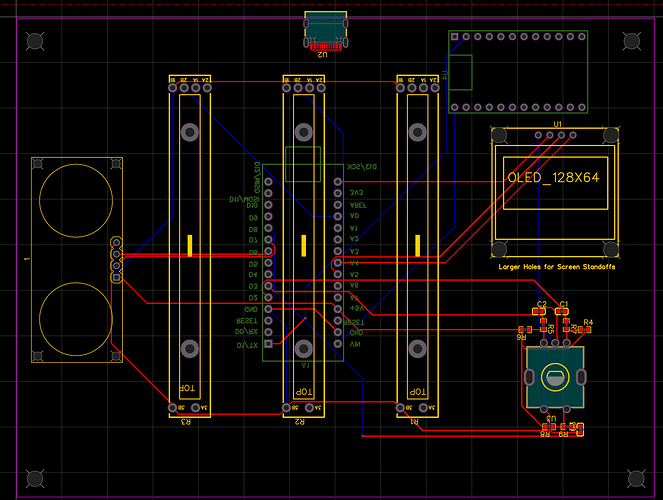

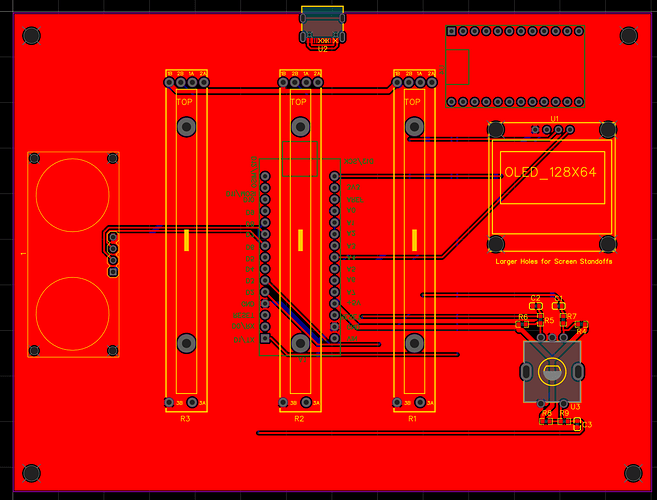

This should now hopefully be correct (?):

- Measure the mounting holes in the existing OLED (diameter and spacing)

- ...

Maybe I'm misunderstanding what you mean, but isnt what you are describing, what I've already got going (in regards to the PCB)? If I understand correctly, I just need to remove the current header and add stand-offs to the 4 screw-holes and solder the OLED pins directly to the PCB, correct?

Basically like this, just with correct stand-offs (I dont dont currently have fitting ones on hand):

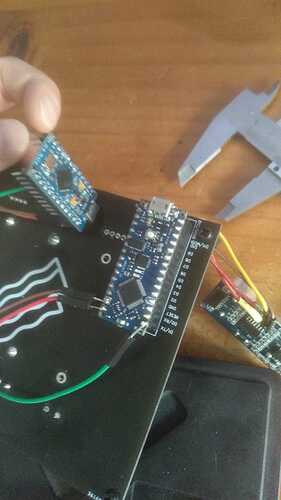

I was panning on soldering it onto the board, just like I did with the NanoEvery (in this case I added some headers so I can remove it for Testing purposes as I am still in development).

The ProMicro is currently only connected via some jumper wire (while I sort out the PCB design).

The Pro Micro is currently connected via the USB connector and delivers power to the NanoEvery via the RAW pin (AFAIK its some kind of direct-passthrough of USB power). Additionally I have the GRD and RX Pins connected (receiving MIDI data from NanoEvery).

Long-term I am hoping to redesign everything and have it working on a single chip, but that's something for for the future.

I'd also like to then replace the arduino board and mount the ATMega32U4 chip directly to the PCB instead of having the Arduino Daughter Boards on there. But that's something (again) for the future.

Instead of using headers, I suppose a proper DIP socket would be the nicer mounting option.

The reason I dont want to use the USB connector on the ProMicro is that the board is in the way (the usb connector is pretty much flush with the board). I want to manufactur a nice chassis and want the footpring to be as small as possible. Having only the USB connector (instead of the entire board+connector) gives me more flexibility on the placement of the USB connector, and the design of the chassis. Also, USB-C is the superior USB connector in every way, so if I add USB anyway, I want it to be the best type of USB connector.

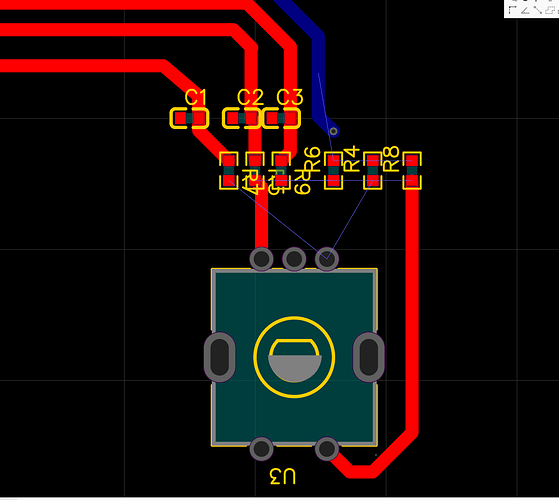

EDIT: Is there a "best practice" when it comes to the layout of resistors and capacitors? I'm struggeling with the layout on the PCB. Looks very messy, and I cant seem to get the VCC connected to the Via (software doesnt seem to let me).

EDIT2: I found out there is an "Auto Route" option. If only I'd known that 6months ago when I did the first PCB

AFAIK now all I need to do is get the USB-C connected