westfw:

Do you have a sneaky easy way to cut those slots?

I have used 3 methods to accommodate the hose clamp.

- Drill a starting and ending hole at the hose clamp width dimensions.

Use a cut-off wheel to cut most of the material.

Shape the slot with an auger bit file.

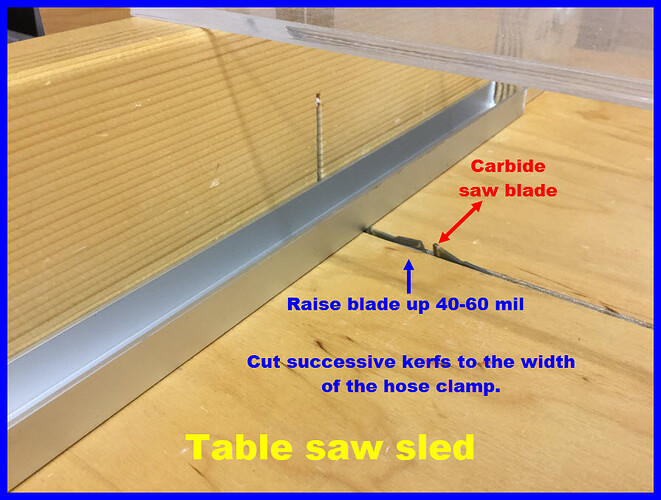

Cutting oil is useful. - Using a table saw sled, nibble out a slot wide enough for the hose clamp.

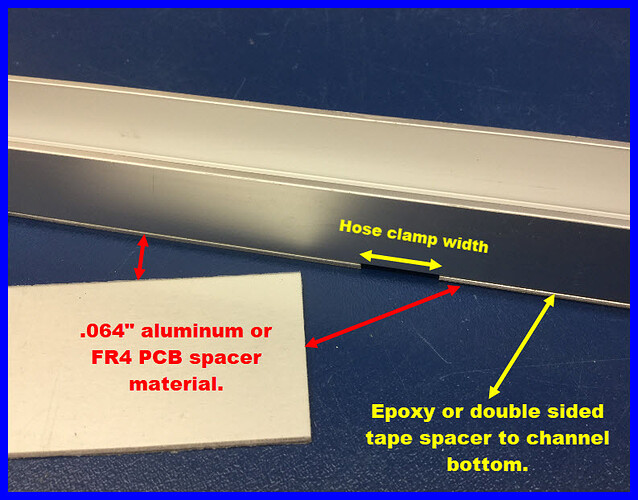

- Use two spacers under the channel.

Hose clamp thickness is typically .025”.