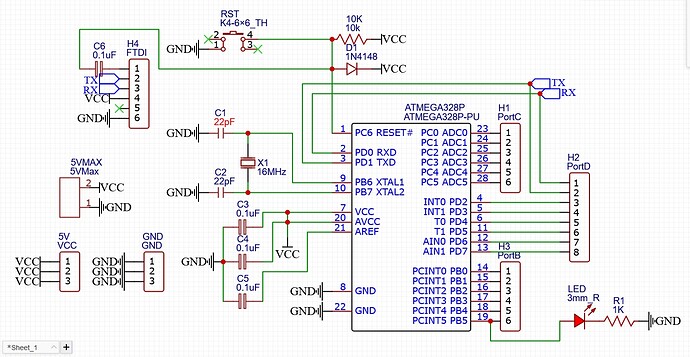

As a way to more fully understand the inner workings of an Arduino, I tried to make a minimal ATMEGA328P board on a small footprint (3cm × 6cm) PCB. I learned quite a bit. See the attached files that illustrate my attempt.

My question is, did I miss anything? Will this work?

I apologize if this is the wrong forum for this question or if it is an inappropriate question to ask. I am rather new to all of this. Any input would be greatly appreciated.

I recognize that this ATMEGA328P will have to be programmed before inserting it in this board. I was planning on using a DIP socket.

You should have some small decoupling caps near to the 328 across the power supply.

Many, many small footprint PCBs are already available for the ATmega328, and they work. The Dorkboard from 2008 was fun.

An ATmega328 on a breadboard works too.

hammy:

You should have some small decoupling caps near to the 328 across the power supply.

Thanks for the input. I have a 100nF cap after the regulator and a 22uF after the 328. One of the pages jremington suggested above has two 0.1uF on either side of the 328. Would that do the trick?

Vcc and Aref each require a 100 nF bypass cap, as close as possible to the pin.

jremington:

Vcc and Aref each require a 100 nF bypass cap, as close as possible to the pin.

Thanks! Would I still need the 22uF cap at Vcc and the 100nF by the regulator?

by the regulator?

For any complex part, always follow the recommendations in the data sheet and/or the manufacturer's recommended application circuit.

jremington:

For any complex part, always follow the recommendations in the data sheet and/or the manufacturer's recommended application circuit.

+1 you don't have to cast around for this, the manufacturer has you covered.

You need 0.1uF on each of VCC, AVCC, and Aref. Do not connect Aref to +5.

Since you have a button reset, you should also have a diode on parallel with the reset resistor. Cathode to 5V.

I don't see an input cap and output cap on the regulator. Why not skip the regulator and just use a 5V supply, like a phone charger wall wart? Can cut the USB-B connector off the a cable and wire that to the screw terminal (?).

Add an FTDI header, or at least make it easy connect an FTDI Basic, with a DTR pin goes thru a 0.1uF cap to reset.

Rx, Tx, DTR, 5V, Gnd are needed.

Test your LED/Resistor before soldering them in. 220 could be really bright.

Having signal traces go under the crystal traces is not good, they could interfere with the crystals.. Move components around to eliminate that.

Here are a couple of examples. No diode on reset, I did these prior the recognition that the reset switch could cause a voltage spike that the chip was detecting as the start of High Voltage programming mode (in error).

It looks good. What software did you use to develop the board ?

The yellow makings are, I guess, from the silk screen layer to appear on the board (i.e. not a fabrication layer).

It is always best to publish the schematic as well for any board review.

I would definitely add an FTDI header to make programming easier.

I would also not want the power led to be so bright (a 1k resistor instead of 220R)

Fascinating exercise in "creative head-banging" but is this board significantly smaller than a Pro Mini?

Does it matter? Good exercise in using the tool; creating a schematic and laying out a board.

Mine were early designs using Eagle. Never actually had boards made.

Like I said, depends on the purpose. ![]()

I was using EasyEDA on-line software.

The yellow markings are the top silk screen, yes.

Sorry I forgot to add a schematic. (See below.)

I am not sure if I will spend money on having the boards made (I am leaning to YES though). It was primarily an exercise to get to know the layout of Arduinos. I have learned quite a bit.

I was thinking that a NANO or PRO MINI might be better as well. Mine is, in fact, much bigger. It is 30mm × 60mm. A NANO is somewhere around 17mm × 43mm and a PRO MINI is around 17mm × 33mm. They are both probably cheaper too.

Now I am trying to think under what circumstances mine would have an advantage.

By the way, thanks so much for all of your input and suggestions. This has been a fun exercise.

I added the diode.

I replaced the caps that were there before with the 104 caps (although I am still not sure if I got them right).

I took out the regulator and that saved a lot of space. Thanks CrossRoads! I guess in my mind I was thinking I wanted to be able to hook up a 9V battery. But the wall wart is a good idea.

I put in the FTDI.

And... I changed the resistor to 1K.

Obviously, it is mainly a design and learning exercise. A barebones Arduino can, however, be useful for low power experiments where you are testing battery consumption etc. But for that, you’d need to add jumpers to isolate the power led and the voltage regulator.

The crystal load capacitors have the wrong value.

Edit.

The voltage regulator has now gone, so the comment above does not apply, but the 7-12 volt socket labeling on the schematic should be revised. Also, the labeling on the ftdi header on the board is misleading.

The crystal load capacitors have the wrong value.

They seemed wrong when I plugged in the labels. Thanks.

22pF caps are usually 0.1"/2.54mm pitch, similar to the 0.1uF caps.