Hi guys. I can't any reaction out of RFID chip

I soldered my RFID RC522 yesterday.

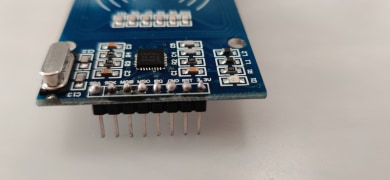

On my first Attempt it ended up like Pic1

I was told to re-do it and the second (and current) version looks like Pic2

I did NOT plug the RC522 before i reached Pic2

Now.. I tried running the "DumpInfo" example and connected the pins as it says but still no reaction..

Can someone point me in the right direction? Is it firmware, soldering or something else maybe?

Code

/*

* --------------------------------------------------------------------------------------------------------------------

* Example sketch/program showing how to read data from a PICC to serial.

* --------------------------------------------------------------------------------------------------------------------

* This is a MFRC522 library example; for further details and other examples see: https://github.com/miguelbalboa/rfid

*

* Example sketch/program showing how to read data from a PICC (that is: a RFID Tag or Card) using a MFRC522 based RFID

* Reader on the Arduino SPI interface.

*

* When the Arduino and the MFRC522 module are connected (see the pin layout below), load this sketch into Arduino IDE

* then verify/compile and upload it. To see the output: use Tools, Serial Monitor of the IDE (hit Ctrl+Shft+M). When

* you present a PICC (that is: a RFID Tag or Card) at reading distance of the MFRC522 Reader/PCD, the serial output

* will show the ID/UID, type and any data blocks it can read. Note: you may see "Timeout in communication" messages

* when removing the PICC from reading distance too early.

*

* If your reader supports it, this sketch/program will read all the PICCs presented (that is: multiple tag reading).

* So if you stack two or more PICCs on top of each other and present them to the reader, it will first output all

* details of the first and then the next PICC. Note that this may take some time as all data blocks are dumped, so

* keep the PICCs at reading distance until complete.

*

* @license Released into the public domain.

*

* Typical pin layout used:

* -----------------------------------------------------------------------------------------

* MFRC522 Arduino Arduino Arduino Arduino Arduino

* Reader/PCD Uno/101 Mega Nano v3 Leonardo/Micro Pro Micro

* Signal Pin Pin Pin Pin Pin Pin

* -----------------------------------------------------------------------------------------

* RST/Reset RST 9 5 D9 RESET/ICSP-5 RST

* SPI SS SDA(SS) 10 53 D10 10 10

* SPI MOSI MOSI 11 / ICSP-4 51 D11 ICSP-4 16

* SPI MISO MISO 12 / ICSP-1 50 D12 ICSP-1 14

* SPI SCK SCK 13 / ICSP-3 52 D13 ICSP-3 15

*/

#include <SPI.h>

#include <MFRC522.h>

#define RST_PIN 9 // Configurable, see typical pin layout above

#define SS_PIN 10 // Configurable, see typical pin layout above

MFRC522 mfrc522(SS_PIN, RST_PIN); // Create MFRC522 instance

void setup() {

Serial.begin(9600); // Initialize serial communications with the PC

while (!Serial); // Do nothing if no serial port is opened (added for Arduinos based on ATMEGA32U4)

SPI.begin(); // Init SPI bus

mfrc522.PCD_Init(); // Init MFRC522

delay(4); // Optional delay. Some board do need more time after init to be ready, see Readme

mfrc522.PCD_DumpVersionToSerial(); // Show details of PCD - MFRC522 Card Reader details

Serial.println(F("Scan PICC to see UID, SAK, type, and data blocks..."));

}

void loop() {

// Reset the loop if no new card present on the sensor/reader. This saves the entire process when idle.

if ( ! mfrc522.PICC_IsNewCardPresent()) {

return;

}

// Select one of the cards

if ( ! mfrc522.PICC_ReadCardSerial()) {

return;

}

// Dump debug info about the card; PICC_HaltA() is automatically called

mfrc522.PICC_DumpToSerial(&(mfrc522.uid));

}