EDIT-1: The solution to the problem is (partly) given in my next post (#7).

EDIT-2: A pin / wiring layout of this (small) project is given in post #13 and #14.

Hello all,

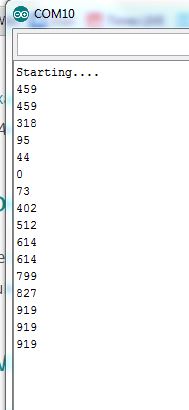

I am encountering strange behavior when connecting a TowerPro MG995 to my Arduino UNO. I've tried many setups, e. g., connecting it directly to the Arduino or using a potentiometer to control the final position of the servo---always with the same behavior: The servo roughly drives to the commanded position but than moves back randomly. Using a for-loop to let the servo occupy all possible angles (0-179°), was weird too: At first, the motions were comparable to the first test case (moving back and forward) but after some seconds the servo stopped moving at all (just a humming noise when a new position was send by the Arduino). Note that I am using the (default) "Servo"-Arduino library.

I've uploaded a video demonstrating this behavor (using the "poti-setup"). You can download it here. The code for this setup is as follows (taken from here):

#include <Servo.h>

Servo myservo;

int potpin = 0;

int val;

void setup()

{

myservo.attach(9);

}

void loop()

{

val = analogRead(potpin);

val = map(val, 0, 1023, 0, 179);

myservo.write(val);

delay(15);

}

Additionally, I've tried the following:

- Used an external power plug: The servo appeared to be more reactive but the overall "strange" behavior was the same.

- Connected another servo (TowerPro SG90): This servo worked well. Using the "poti-setup", I was able to set the position of the servo using the poti (as expected).

Does anyone have any idea what the problem is? I am assuming that the servo devices (BTW: both servos I am owning have this problem, except for the SG90) are simply broken ...? Any hints / suggestions are highly appreciated!

Thanks in advance!

Best regards,

CodeFinder

PS: I have another video showing the (working) result of connecting the SG90. If you need it, I can upload it as well. If you need more information, just ask me.