Thanks everyone for the input! Power economics is truly an art form!

I have replied to every one of your comments below.

Yep 2032 coin battery. Thanks for pointing out the error.

Chrisknightley

“it is necessary to retain the "previously transmitted voltage"

What I imagined is the “previously transmitted voltage” level could be stored in a capacitor attached to the comparator. When the comparator output toggles (because a difference has occurred) the cap gets recharged via the comparator output (through a diode). Several issues with what I just explained, but it is meant to seed further thought. My attraction to comparators does little to solve the problem if the pot is still bridging the rails.

Chrisknightley

“sleep on a regular basis, acquire the POT value with the ADC, “

Perhaps this will be the end solution. As you point out, the MCU outputs are the only way to interrupt the load of the pot. If polling periodically, the power economics possibly favor using the internal comparator, there is a little dance with the comparator register, but on lay glance, it looks like a couple dozen clock cycles (see Smajdalf comments below - I am wrong about this). Where the ADC takes 13 to 25 cycles per sample, not including the preparatory overhead. That said there is a sleep mode referred to as ADC noise reduction meant to quiet things down during a conversion, which may counterbalance the clock cycle difference between being fully awake. Seems like an advanced, bare metal, hack. —NOTE smajdalf sheds light later - I am probably wrong here….

TomGeorge

“Have you breadboarded this circuit to see if your proposal works.”

No I am looking for a jumping off point. Being a non-EE, I reached out for opinions and insight.

TomGeorge

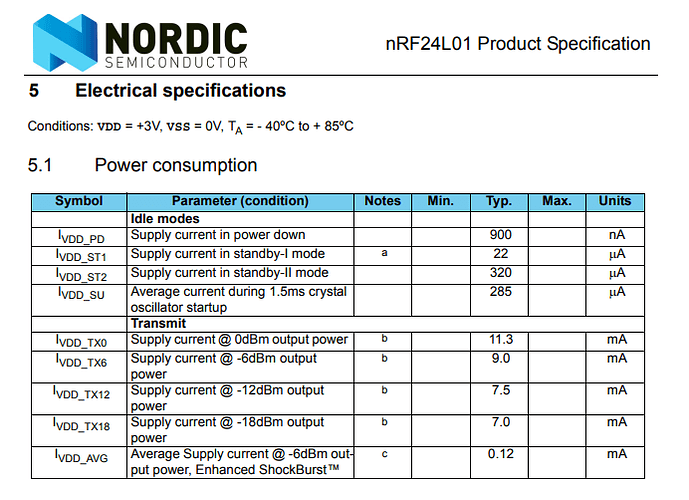

“I am not sure the CR2023 will be able to provide the pulse energy for the NRF when it transmits.”

My transmit distance is 2 meters, the nRF24l01 at -18dBm will draw about 7ma. I sourced this information from Table 5.1 of the nRF24l01 datasheet (see chrisnightly’s embed above). Is there another power domain element that I have overlooked?

smajdalf

“to reduce current consumption of the pot connect it to MOSI instead of Vcc.”

That’s interesting! Would this effect the SPI coms? Conditional reassignment? And most importantly, what would the benefit be? Super curious!

hzrnbgy

“utilize the IRQ pin from the NRF to signal the MCU, so you don't have to "poll" it”

I may have misunderstood your idea. The MCU needs to wake on the movement of a local pot. Your concept, if I have understood you properly, would wake the MCU on receipt of incoming radio data.

paulRB

“You would need to use some high-pass filter on the pot output”

“But you would need to detect a change in either direction, and I'm not sure how that could be achieved.”

I am not understanding what role a high pass filter would serve. I was thinking low-pass, to filter emi/rfi. With careful filtering, perhaps a high impedance pot can be used. “...either direction…”

Good point - perhaps bi-polar sensitivity could possibly be achieved by a dual comparator, one blind to positive, one blind to negative. ??

markT

Use a 1M pot and add 10nF or so between wiper and ground to provide a stable and low-impedance source for the on-chip ADC to sample. A 1M pot … would take 9 years for this to discharge …

Thanks mark, I will breadboard this and put it on my scope and hook it to an arduino for testing.

Smajdalf

“Internal comparator cannot be used. It needs too much current. “

My intuition was wrong - is it a software comparator?? I just ctrl-f’d the data sheet, and I am seeing “8-bit comparator”. Further data sheet study awaits me.

Smajdalf

“How quickly is needed to react to the pot change?”

extended dormancy >60 minutes: 100ms

standby: i.e. 1 to 60 minutes since last change: 20ms

active: 5ms (MCU would be idle)

Great comments - thank you so much!!

Dan

San Jose, CA