Thank you for explaining. Learned something new.

^ Railroader gets it.

Try to accomplish your task with 1/2 the parts. Better yet, 1/5 the parts. All this to change a fan speed based on air quality measurements?

15 years as a HAZMAT specialist, I can assure you this: if the AQ is anything less than ideal, the fan goes 100%

The pollution is not in life threatening levels, it is just moisture and Voc gasses. I don't think %100 fan is necessary. Also I think I used pretty much the minimum amount of parts.

BTW I'm not sure but I found the reason of the burn. It might be because of the uneven grounds between high power side and low power side. They should have been equal. Details:

100% is absolutely necessary, or else you have the wrong fan. VOCs cause cancer. VOCs can explode. VOCs cause acute effects that I'd rather buy a new fan over than even one headache, besides fans last years even at 100%. The "V" is VOC is for volatile. Who cares, right? Well, it means you've lost control of the substance and the goal is firstly to reduce that potential deleterious effect on humans to zero (and I do mean zero) and secondly, well there is no second place.

Hi,

What is your electronics, programming, arduino, hardware experience?

Note that the drive has to have a COM connection to the source of the lower MOSFET....

But before all that, can you please post an image of the other side of your board?

- Having 230Vac mains on these "prototyping" type boards is very dangerous.

- Having your Nano working in a 230Vac circuit is very dangerous to not just the operator but as a fire hazard.

- Note that your sensor will also be at 230Vac potential and may not have the insulation to make it a safe device, have you looked at the sensor specs to see what its gnd insulation is rated at?

- Also the insulation rating on the four potentiometers.

- Your fuse is in the wrong place.

- Your power supply is not designed for constant voltage but constant current for LED lights. So its output voltage could be more that the max rated Vraw input voltage of the Nano.

Questions;

- Do you have the spec of the LED power supply?

- Did you measure it's output before attaching the NANO?

- How do you know the power supply has 12V ouptut?

- Do you know the difference between a specifically designed LED power supply and a regulated voltage output power supply?

Tom... ![]()

![]()

![]()

![]()

Yep and I conected it to Arduino's ground instead of MOSFET's that was the main problem.

Amateur in all fields, I am a new graduate from control engineering with no work experience.

Yeah I realized it very later, it should be after the rectification I guess.

Okay, the LED driver is just a name market gives, it is probably a Flyback voltage regulator and it has constant voltage I checked it, the market calls it a LED driver because it has low output power. (6 Watts, 12V, 0.5 Amps max)

Yes

Sorry to confuse you.

Btw it is a pro mini not a nano but doesn't matter I guess.

No.

It should be close to the power input so it protects all your circuitry.

What do the four potentiometers do?

Are they front panel controls or on board trim pots?

Thanks.. Tom... ![]()

![]()

![]()

![]()

Oh, I was only concerned about my custom H bridge lol. Also the Power supply has it's own fuse probably. And 3 Amps is much more than enough to destroy it so I don't think 3 A fuse would protect it ![]()

- Set refererance, 2. Set Kp, 3. Set Ki, 4. Set Kd

The coefficients for PID controller. They were front panel controls. For slow systems such as air quality system, the derivative term might be ignored but I've added it anyway. The controller part was working greatly btw. I conected the output to a LED before the H bridge drivers. I could watch how the led blink frequency change and I could imagine the fan spinning already. Well R.I.P

Nail on the head @TomGeorge !

@prince_charming

I cant see any supply connection to your several earth points

have you calculated the ripple current in C15?

H

No it doesn't, but do you have the mains turned ON when you connect your USB adapter to program the ProMini?

Can you identify in the ProMini what component fails, does any smoke come out?

Have you got the ProMini plugged or soldered in?

If you plug it into headers, then you can power up your project and CAREFULLY measure the voltages at the pins.

I strongly suggest you dump that design and use a safer isolated solution.

Tom.... ![]()

![]()

![]()

![]()

PS, Are you aware that slowing down a motor will probably reduce any cooling device it has built in, that is fan blades for the motor itself. The motor may run hot as you slow it down and you may need extra cooling to help it perform.

What is the application of the fan?

Can you also consider alternative solutions which provide better isolation from mains voltages such as (1) a low voltage fan or, if it must be at mains voltage, (2) a solution with an optically isolated triac/diac pair such as described here: Dimming effect by zero crossing detector and a triac

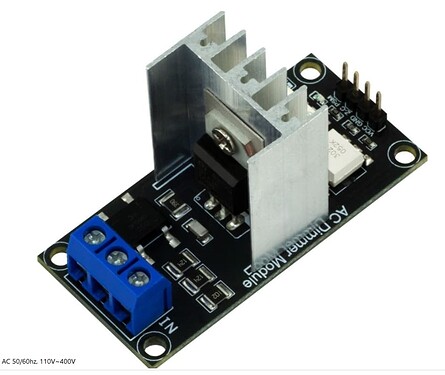

You can also get ready made modules: https://robotdyn.com/ac-light-dimmer-module-1-channel-3-3v-5v-logic-ac-50-60hz-220v-110v.html

Even if you get your current solution working satisfactorily, absolutely everything has to be insulated to prevent the user coming into contact with any otherwise exposed metal parts.

Also 12v LED PSUs may not be isolated. In my experience they are dreadful, poorly regulated, cheaply made, best avoided except for their intended application.

Do you mean there is no connection between H bridge ground and power supply ground? I should have done at and maybe I could avoid the burn.

No I plug it out.

First the regulator got really hot, I removed it and connected to VCC via USB this time the chip got really hot. I measured the resistance between VCC and GND and it was 10 ohms with regulator and 18 ohms without. Current basically penetrated the Arduino otherwise the resistance would be much greater.

Soldered. I removed the Led PSU btw, since there is no regulator the voltage will probably be 5V but the current is, wooaahhh probably 500mA or something.

Yeah we discussed that in stack electrical, they said the same. I shouldn't underestimate isolation.

I will reduce the voltage as I reduce the frequency, I will keep 4.4 V/Hz ratio. So I guess it wont heat?

It's a window fan.

Triacs aren't the best way o control AC motors because AC motor will try to catch the coil magnetic field rotation rate and that's all about frequency. Lowering the voltage with triac will decrease the torque and eventually the speed will get lower but still, you can't precisely determine the speed of fan with triac. Am I wrong?

What size does the fan have and how much electric power does the fan have?

For something in the 5W to 20 Watt size. Replace with a DC-Fan

Your aim is reducing variate the rpm of the fan. What is the final effect of the fan running?

How much precision is needed in this final effect?

best regards Stefan

Arduino clone has a poor regulator that can't keep up with 12V Raw input?

Possibly. The behavior you describe sounds exactly like what happens when a linear regulator goes into thermal shutdown. I haven't had trouble with 12V at Arduino Vin terminal, but I've heard that some people have.

Also, note that according to your schematic, it's possible to put 12V into the analog inputs depending on the position of those pots. This is Not Wise.

What size does the fan have and how much electric power does the fan have?

50Watt , 20cm diameter and 1400 rpm.

What is the final effect of the fan running?

What do you mean? It can clear cigar smoke quickly as much as I know, I used it in another project that's why I know (if interested: https://youtu.be/ZWUWvB_GEJE (beginner level circuit design)).

How much precision is needed in this final effect?

Not too much actually but I don't know how much precision will voltage control bring, that's why I was concerned. I watched a video on Youtube about a motor with no load, it didn't even drop single RMP even though the voltage was halved. If load was there rpm would drop I guess but who knows how much?

The behavior you describe sounds exactly like what happens when a linear regulator goes into thermal shutdown.

Ohh okay, I tested every component except the H bridge in a breadboard before, probably the wrong ground connection at MOSFET drivers caused it to heat up and eventually burn.

note that according to your schematic, it's possible to put 12V into the analog inputs depending on the position of those pots.

The arrows on pots are connected to VCC not 12V.

This topic was automatically closed 180 days after the last reply. New replies are no longer allowed.