12V measures 12.3V

Arduino measures 4.98V (from 12V supply)

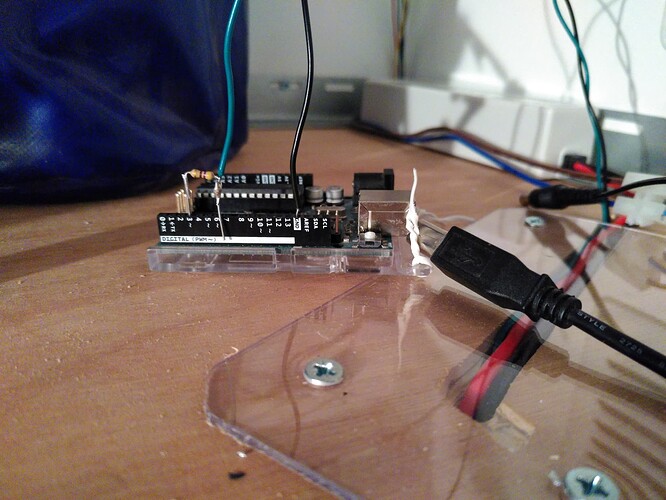

The connectors you stick into the Arduino are unreliable. You should use male-header pins which are square in shape and fit much better.

That actually is more than the Arduino's regulator is rated for as an input. Though it seems functional, i would make sure programmatically that it isn't shutting down periodically due to overheating. Something simple that lights up the built in LED for 10 seconds when the sketch starts would probably do.

Always does. Just confirm with a multimeter that there are no shorts between Vcc & data terminals & GND anywhere but the 1st Bin & GND, and that the 5v rail on the strip is actually powered.

I get it from the fact that the OP is not able to set the power supply to exactly 5V but something higher. Common sense suggests that because of that you are better trying to set the power supply just under rather than just over.

Your picture shows not only a strip with no ceramic capacitors on each chip, but also no place to solder one. ![]()

Saw that as well, and thought hmmm. But i am not so familiar with WS2813's and when i saw a closeup picture here it appears as if there is an internal one. Can't tell for sure but there is 2 extra elements in the LED that are not in a WS2812b

That OP said there was no way to adjust it. I have a PSU like that, and it also produces something like that. I also have ones that put out 5v nearly exactly, but those are a bit less powerful.

I thought drift was related to fluctuations in voltage ? A double-coil would drift with the drift in the AC-mains. Modern PSU's don't really do that.

Yes, there is definitely much misleading and confusing information running about.

From what would you actually imagine the Arduino needs "protecting"? ![]()

ATmega328 absolute maximum voltage is 6.0 V.

I have had the same issue with WS2813s and speculated a lot. Read all of the comments carefully but non of them seemed to be really the problem and neither worked.

So used oscilloscope to track the signal along the strip and found out that source of the problem is some of LEDs in the strip and came across this explanation:

And for the initial working and then going crazy my explanation is that when soldering process isn't executed correctly some of them get damaged but in few seconds QC test doesn't show up and when left on for a while (in my case few minutes) the accumulated heat causes damaged LEDs go crazy and finally go off. this process goes on till two adjacent LEDs shut down and all of the rest goes off too.

I tried to find the corrupted ones and replace them according the datasheet time and temperature table (albeit according to the link above 20'C less than datasheet recommended Temperature) and now strip runs smoothly.

This topic was automatically closed 180 days after the last reply. New replies are no longer allowed.