Hi folks,

I'm trying to motorise a wardrobe setup and have prepared the hardware part, but now I'm somewhat stuck on the programming task. I'm an architect, so programming is something new to me, but I'm trying to understand it as much as possible and trying to learn and watch tons of videos.

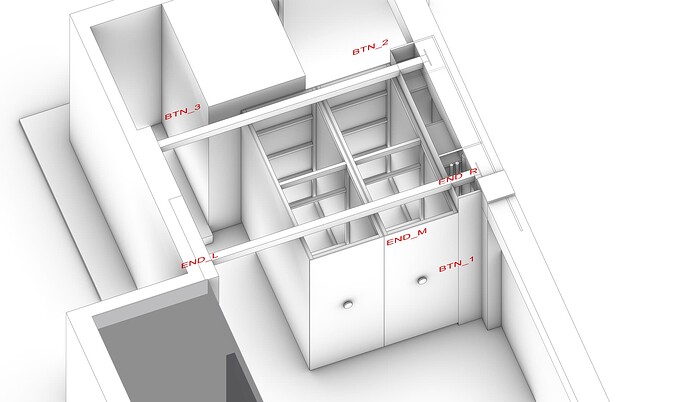

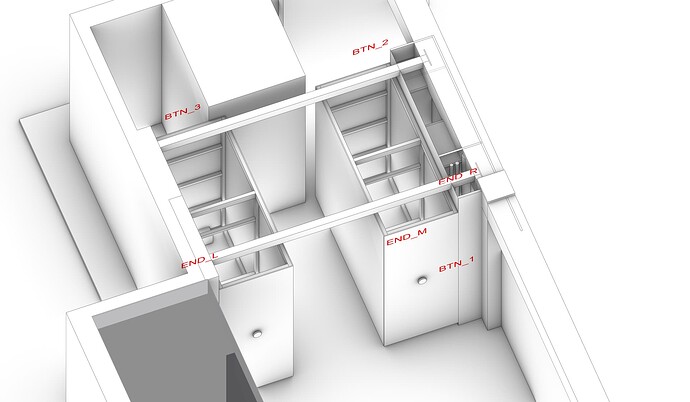

I have this schematic of how I have everything connected. Right now I'm doing the test part and I'm working my way through simpler code to more complex one.

I managed to write code, that moves both motors while holding any of the buttons. If I release the button and hold it again, the direction is reversed. If the endstop is being touched, it stops both motors and starts moving in the opposite direction with a small delay (so I would be able to release the button and the "home" position). This was pretty ok and fun, but now I'm at the trickier part.

I'm adding the third moving endstop (it is moving with wardrobe 2) and I have to come up with some logic on how to move the wardrobes. My first intention was to move one wardrobe at a time (to not put that much load on the power supply). When I press the button it should start moving W1 or W2 based on the last direction (the direction changes with each button press). Then it hits one of the end stops (L or R) and then it should start moving the other wardrobe to the Middle endstop. If Middle and L/R are pressed it has to move to the non-activated endstop and after hitting it it stops or if I still hold the button it has to start moving the other wardrobe. If just L/R is activated, it should move the other wardrobe to the M stop.

There are a lot of other problems I guess, but I don't have any idea, how to handle this kind of logic/variable-based code.

Do you have some inspiration, that I could read/watch to find some solution for this?

Here is the code, that I managed to test with the motors and end stops.

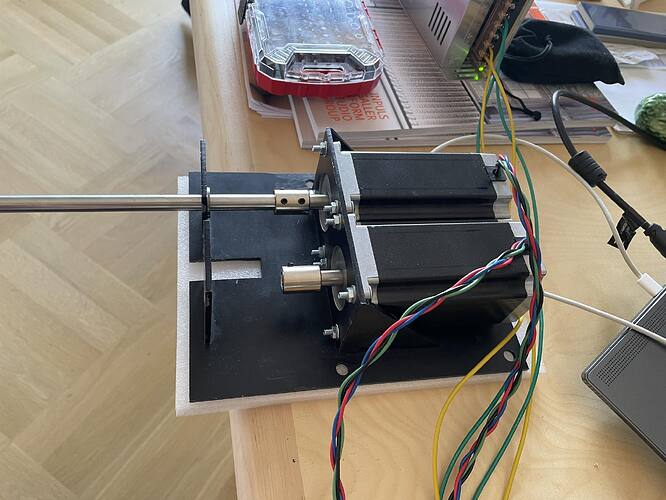

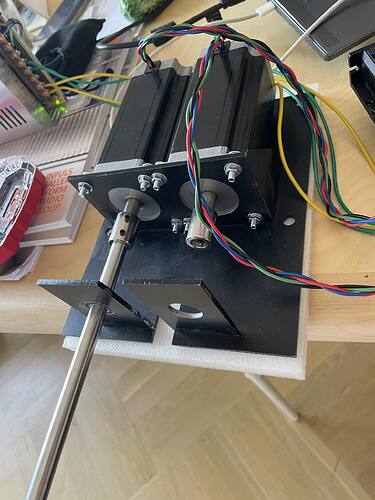

And pictures of the setup of the motor, some parts are missing, but I will add those once I install it in place.

Thank you for any advice or good word, I appreciate it. ![]()

```cpp

#include <AccelStepper.h>

// Buttons

#define BTN_1 4 // Button - entrance (to bedroom)

#define BTN_2 5 // Button - exit (from bedroom)

#define BTN_3 6 // Button - hideout

// Endstops

#define END_L A0 // Endstop - left

#define END_R A2 // Endstop - right

// Stepper motor pins for the left stepper

#define STEP_L 7 // Define step pin (pulse pin) for the left stepper motor

#define DIR_L 8 // Define direction pin for the left stepper motor

#define ENA_L 9 // Define enable pin for the left stepper motor

// Stepper motor pins for the right stepper

#define STEP_R 10 // Define step pin (pulse pin) for the right stepper motor

#define DIR_R 11 // Define direction pin for the right stepper motor

#define ENA_R 12 // Define enable pin for the right stepper motor

// Alarm pin connected from both stepper drivers - NOT USING THOSE YET

#define ALM 13

// SSR for reseting power to the power supply of stepper drivers - NOT USING THOSE YET

#define SSR A3

AccelStepper stepperL(AccelStepper::DRIVER, STEP_L, DIR_L);

AccelStepper stepperR(AccelStepper::DRIVER, STEP_R, DIR_R);

// Variables - button states and endstop states

bool btn1_state = false; // actual button state

bool btn2_state = false; // actual button state

bool btn3_state = false; // actual button state

bool lastBtn1_state = false; // previous button state

bool lastBtn2_state = false; // previous button state

bool lastBtn3_state = false; // previous button state

bool END_L_STATE = false; // actual endstop state

bool END_R_STATE = false; // actual endstop state

bool lastEND_L_STATE = false; // previous endstop state

bool lastEND_R_STATE = false; // previous endstop state

bool direction = true; // true = right, false = left

bool waitingForDelay = false; // flag to check if waiting for delay

unsigned long endstopHitTime = 0;

const unsigned long endstopDelay = 700; // Delay in milliseconds

void setup() {

// Initialize the buttons

pinMode(BTN_1, INPUT_PULLUP);

pinMode(BTN_2, INPUT_PULLUP);

pinMode(BTN_3, INPUT_PULLUP);

// Initialize the endstops

pinMode(END_L, INPUT_PULLUP);

pinMode(END_R, INPUT_PULLUP);

// Initialize the left stepper motor

stepperL.setMaxSpeed(400); // Set maximum speed

stepperL.setAcceleration(100); // Set acceleration

stepperL.setEnablePin(ENA_L);

stepperL.setPinsInverted(false, false, true);

stepperL.disableOutputs();

// Initialize the right stepper motor

stepperR.setMaxSpeed(400);

stepperR.setAcceleration(100);

stepperR.setEnablePin(ENA_R);

stepperR.setPinsInverted(false, false, true);

stepperR.disableOutputs();

}

void loop() {

// Update button and endstop states

updateButtonStates();

updateEndstopStates();

unsigned long currentMillis = millis(); // Save current millis to be able to add delay after hitting endstop and reversing movement

if (waitingForDelay) {

// Check if the delay period has passed

if (currentMillis - endstopHitTime >= endstopDelay) {

waitingForDelay = false;

} else {

return; // Exit the loop until delay period has passed

}

}

// Check if any button is pressed

if (btn1_state || btn2_state || btn3_state) {

// Enable the stepper motors

stepperL.enableOutputs();

stepperR.enableOutputs();

// Move the motors in the current direction

if (direction) {

if (!END_R_STATE) { // Allow movement if right endstop is not triggered

stepperL.moveTo(stepperL.currentPosition() + 10000); // Greater movement then current position and physicall limitations (

stepperR.moveTo(stepperR.currentPosition() + 10000); // will be adjusted to be sligtly more then real physicall limitations)

}

} else {

if (!END_L_STATE) { // Allow movement if left endstop is not triggered

stepperL.moveTo(stepperL.currentPosition() - 10000);

stepperR.moveTo(stepperR.currentPosition() - 10000);

}

// Run the motors while any button is pressed

while ((btn1_state || btn2_state || btn3_state)) {

stepperL.run();

stepperR.run();

// Update button and endstop states

updateButtonStates();

updateEndstopStates();

// Check if an endstop is hit

if (END_L_STATE && !direction) {

// Left endstop reached and moving left

direction = true; // Change direction to right

stepperL.setCurrentPosition(0); // Reset position

stepperR.setCurrentPosition(0); // Reset position

endstopHitTime = millis();

waitingForDelay = true;

break;

}

if (END_R_STATE && direction) {

// Right endstop reached and moving right

direction = false; // Change direction to left

stepperL.setCurrentPosition(0); // Reset position

stepperR.setCurrentPosition(0); // Reset position

endstopHitTime = millis();

waitingForDelay = true;

break;

}

}

// Disable the stepper motors to save power

stepperL.disableOutputs();

stepperR.disableOutputs();

} else {

// Reset positions to 0 when no button is pressed

direction = !direction; // Switch the direction for the next press

stepperL.setCurrentPosition(0);

stepperR.setCurrentPosition(0);

}

}

void updateButtonStates() {

lastBtn1_state = btn1_state;

lastBtn2_state = btn2_state;

lastBtn3_state = btn3_state;

btn1_state = (digitalRead(BTN_1) == LOW);

btn2_state = (digitalRead(BTN_2) == LOW);

btn3_state = (digitalRead(BTN_3) == LOW);

}

void updateEndstopStates() {

lastEND_L_STATE = END_L_STATE;

lastEND_R_STATE = END_R_STATE;

END_L_STATE = (digitalRead(END_L) == LOW);

END_R_STATE = (digitalRead(END_R) == LOW);

}