Hi there and thanks for your advice !

Project Outlines:

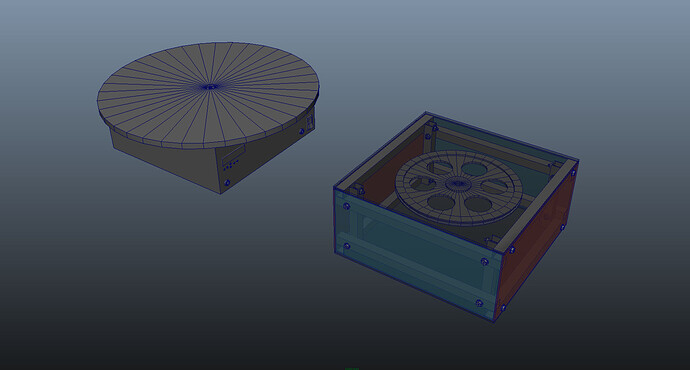

- motorized Lazy Susan ( yes, I know, it's been done a thousand times )

- it is for object VR photography ( rotate a product on the table while taking photos of it )

- realistically I need it to work with loads up to 10kg on a platform that should fit a normal kitchen chair

- the ambitious version should work with loads as large as 100kg ( a person's average weight ? )

- I want it to be autonomous - no connection to computer required while operating

- should have a display ( 2 lines x 16 chars should be enough ) for routine presets or custom cycles, and buttons to input these

- for custom settings I want to be able to set number of photos or degree intervals, pauses between shots

- I need it to trigger the camera ( just closing a circuit )

- maybe a buzzer also for marking the progress, cycle start, cycle ending, feed back on pushing those little buttons

Why don't I want to do it manually ? Because I am a lazy ass, because 36 flashes even with my eyes closed is too much for me. And when you have 10 things to shoot is even worse. Then, something breaks your attention, and you have no idea if you shot position 13 or not. Or if all the flashes went off, because you went at it too soon, and the strobes didn't load fully. So, you see, when one does it manually, there is a thing called human error that ruins it all. Besides this, I love DIY projects.

Questions:

- What Arduino board should I use ?

Can I control the stepper motor shield and the display and the camera triggering and the beeper with one Arduino board ? Do i need the Mega 2560 ? - How powerful does the stepper motor needs to be ? I plan using a small timing pulley on the engine and a rather large wheel inside the "box" to drive the table on top, connected to the motor by a some belt. It will be in the range of 300mm diameter for the big wheel and 25mm on the engine cog. The external platform will be 400 to 600 mm diameter.

- If I need to use a motor that requires more amps than the Arduino can provide, how do I power the engine from external source ? I couldn't figure this so far. If you would like to give an answer .. this is where I am most confused.

- Do I really need a bread board ? Don't like those wires running in all directions. Don't pick on me on this please, excuse my ignorance.

- What do you recommend for a power supply ? Can I use a computer power supply ?

What I found so far:

Should I use something like this ?

http://shieldlist.org/sparkfun/powerdriver

http://shieldlist.org/robotpower/megamoto

http://www.robotshop.com/ca/productinfo.aspx?pc=RB-Ada-02&lang=en-US

I really want to use one of these:

http://www.robotshop.com/ca/dfrobot-lcd-keypad-shield-arduino-1.html

if not this fancy one:

http://www.robotshop.com/ca/4d-systems-1-5-oled-display-shield-arduino.html

So far I am working on a 3D model of the contraption (mechanical part), once I get it to the right proportions and scale I will post some scr caps.

I am not very good with programming, but I am not very worried about it, I should be able to do it.

Budget

Well, if I can do the electronic part of it for under 200$ I am happy. Obviously at this point I don't have a clear idea of what I need to do. So that could be too little, but if it is more than I need .. I am happy.

Thanks again for all the help and advice.

Much appreciated.

Bspin