I can share this much with you. There are dozens of sensors just like yours out there. They are, for the most part based on a ZMCT103C current transformer. You have that current transformer sitting on a module with an amplifier and a gain pot. A Google of "ZMCT103C 5A Range" will get you a few dozen hits of what you have from a few dozen suppliers.

Basically here is what is going on. The CT alone outputs a current proportional to the measured current. A burden resistor is placed across the CT to generate an AC voltage proportional to the current through the loop. The overview looks a little like this:

ZMCT103C 5A Range Single Phase AC Active Output Onboard Precision Micro Current Transformer Module Current Sensor

Features:

1.Onboard precision micro current transformer

2.High precision op-amp circuit board, do accurate sampling for the signal and appropriate compensation, and other functions

3.The module can measure within 5A current communication , corresponding to output analog quantity can be adjusted

4.PCB board size : 38 (mm) x18.5 (mm)

Package Include:

1 x ZMCT103C 5A Range Single Phase AC Active Output Current Transformer Module

I think (operative word think) the onboard pot can adjust the gain of the amplifier. The signal into your Arduino is an AC sine wave offset because an Arduino can't have an AC signal going below zero volts on an analog input pin.

Here is a typical code example used for using an Arduino and then we can look at it in minor detail.

/*

Made on Dec 22, 2020

By MehranMaleki @ Electropeak

Home

*/

#define calibration_const 355.55

int max_val;

int new_val;

int old_val = 0;

float rms;

float IRMS;

void setup() {

pinMode(A0,INPUT);

Serial.begin(9600);

}

void loop() {

new_val = analogRead(A0);

if(new_val > old_val) {

old_val = new_val;

}

else {

delayMicroseconds(50);

new_val = analogRead(A0);

if(new_val < old_val) {

max_val = old_val;

old_val = 0;

}

rms = max_val * 5.00 * 0.707 / 1024;

IRMS = rms * calibration_const;

Serial.print(" IRMS: ");

Serial.println(IRMS);

delay(1000);

}

}

Yes, you are correct as to a sine wave for the AC current. Also on these units the current must be a sine wave. Even then they leave a little, actually much to be desired. So looking at the code all we are really doing is finding a peak value of the sine wave. That is what this is about:

/*

Made on Dec 22, 2020

By MehranMaleki @ Electropeak

Home

*/

#define calibration_const 355.55

int max_val;

int new_val;

int old_val = 0;

float rms;

float IRMS;

void setup() {

pinMode(A0,INPUT);

Serial.begin(9600);

}

void loop() {

new_val = analogRead(A0);

if(new_val > old_val) {

old_val = new_val;

}

else {

delayMicroseconds(50);

new_val = analogRead(A0);

if(new_val < old_val) {

max_val = old_val;

old_val = 0;

}

rms = max_val * 5.00 * 0.707 / 1024;

IRMS = rms * calibration_const;

Serial.print(" IRMS: ");

Serial.println(IRMS);

delay(1000);

}

}

OK so now we have the peak value of the sine wave. There are other ways using code to get there but this works. So we have the AC peak value. The RMS value of a sine is equal to Epk * 0.707 so the code does that next. Finally we use a calibration constant. In this code the calibration constant is 355.55 . The way the calibration constant is derived is a matter of applying a known current through the CT loop and finding a cal constant that works doing the math.

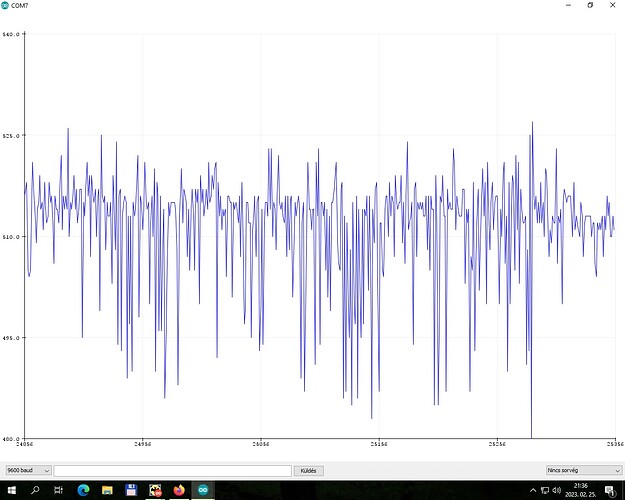

I don't have your CT so here is what I did using the code I posted. I applied a 5.0 volt PK to PK sine wave to A0 on an Arduino Uno. I offset the sine wave by 2.5 volts so 0 volts is my baseline. My peaks are 5.0 volts. Multiple that by 0.707 and we get 3.535 and then multiply by the cal factor of 355.55 and we get 1256.86. Pretty much what we see in the below image.

So that is how it plays out.  Personally there are much, much better AC current sensors. Least I forget the code you see came from here. Personally as to another sensor? I have used very similar to these. Jumper selectable range but you do need a 24 VDC power supply which is inexpensive and a 250 Ohm external resistor. This converts the 4 to 20 mA to a 1 to 5 VDC signal to a uC or Arduino Analog input. Yes, the good AC current transducers cost more but actually have come down in cost for those off the boat.

Personally there are much, much better AC current sensors. Least I forget the code you see came from here. Personally as to another sensor? I have used very similar to these. Jumper selectable range but you do need a 24 VDC power supply which is inexpensive and a 250 Ohm external resistor. This converts the 4 to 20 mA to a 1 to 5 VDC signal to a uC or Arduino Analog input. Yes, the good AC current transducers cost more but actually have come down in cost for those off the boat.

This is the data sheet for the actual CT on your module.

Ron