Let's just start by saying, that while I professionally build vehicles for Motorsports, including chassis, engine, and electrical, the fine electronics side of things have always baffled me. I am attempting to branch out on my personal project to expand my knowledge and potentially use this on future customer builds if and once perfected.

I bought a Amazon special knockoff board with a starter kit a few months back to start playing around the Arduino. I built myself a new sequential shift controller for my sim racer, that also controlled multiple vibrating motors to simulate road and engine feel. I'd love to take credit for doing this, but I relied heavily on forums, diy's and a program called SimHub.

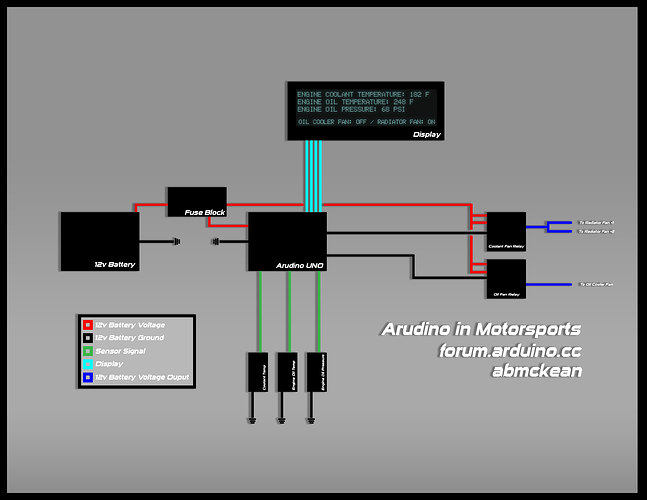

Lately, however, I've been brainstorming the feasibility of using an Arduino with a display to give temperature and pressure readouts based on sensors installed on my engine. Water temp, oil temp, oil pressure, etc. These are all resistance based sensors that are grounded by the chassis/engine block. I would also like to have an output based on water temp and another based on oil temp to trigger a relay for electric fans.

I am confident in the 12v wiring side of things and have attached a quick sketch on how I imagine it being hooked up. However, I'm not sure what the limitations of the board are and, quite frankly, I'm not sure where to start with coding. I'm sure I need to determine the resistance of each sensor at the given temperature or pressure that I want the fans to come on, and creating an output for the fan based on that. I would also need to create a table with voltage/resistances to convert into a temperature or pressure reading for the display.

Aftermarket gauges and fan controllers are nothing new on the market, however I have yet to find a programmable product that can both display sensor readings as well as control fans. A product like this would allow for more control of the systems at hand, as well as others I have yet to think of.

I have the sensors and an UNO from my shifter project to get started with. I have a display from the starter kit I ordered I'd like to use. These don't need to be final components, but I would like to keep my initial investment low until I know it will or will not work.

It would also be interesting to hear what you guys think Arduino (or similar) could be used for in Motorsports.