Hey guys,

as part of my first real in depth project i want to incorporate an analog looking gauge that will show the angle of a hydrofoil (aka 'wedge') on my boat.

I started with the 'motorknob' example in the stepper library and am modifying it to meet my needs.

The hydrofoil moves from a stowed position out of the water(0 degrees) to a 'functional' angle that is about 75-90 degrees. those 15 degrees is what i want to precisely control and display it's position on my gauge. That leaves 74 degrees that is relatively useless on my gauge (not completely useless as i do want to know it's approx position while it's getting deployed). I am measuring the angle of my hydrofoil with a linear 10k pot atached to it's pivot point.

This is the hydrofoil:

and here is how it'll be mounted on my boat:

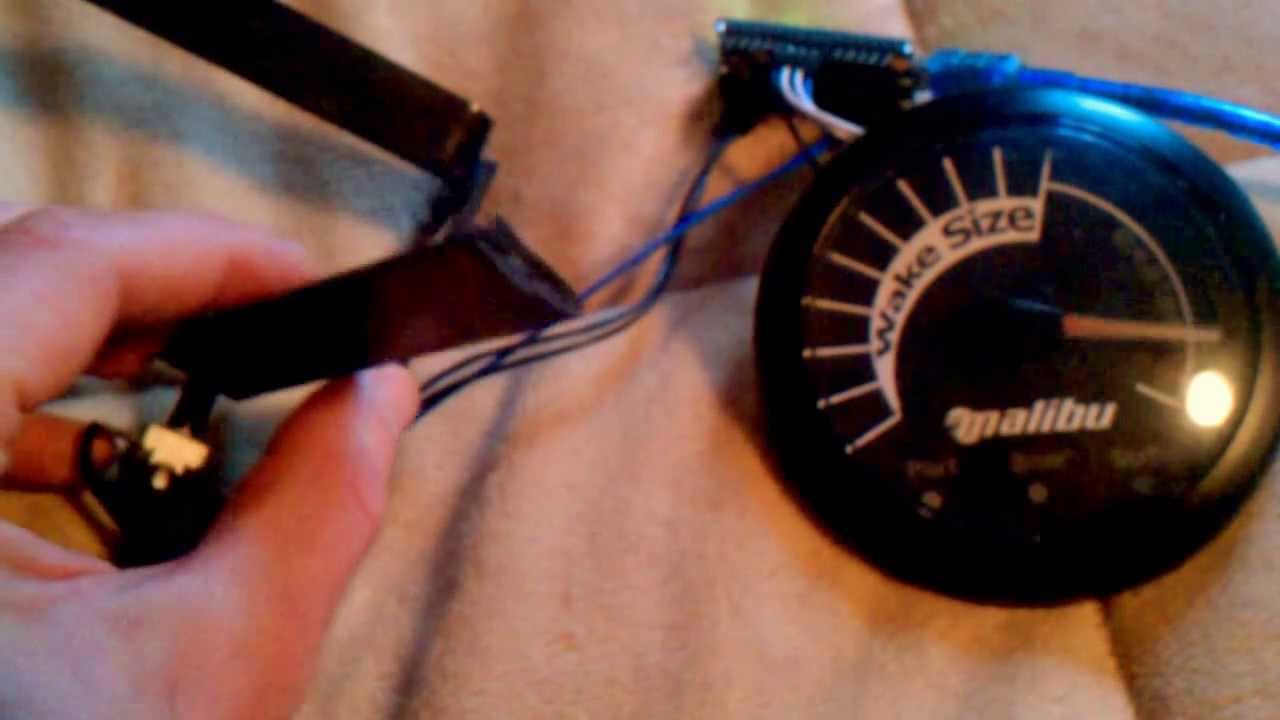

Here is a video of the actual gauge's layout (the plastic piece is just a proxy for the real wedge):

the 'deploy' area is only useful to show me that the wedge is moving from 0 degrees to 75. there is no need for me know the precise angle. So in my code i figured i could remap my sensor's values so that when the pot is is more the 75 degrees it'd 'sweep' a larger area on the gauge, increasing accuracy for those 15 degrees. On the flip side, when it's less the 75 it is represented by a much smaller area of the overall sweep so i adjusted the sensor output with another map function. The problem is, i start to lose 'sync' when the pot sweeps back and fourth.

/*

* WedgeGauge

*/

#include <Stepper.h>

// change this to the number of steps on your motor

#define STEPS (315)

// create an instance of the stepper class, specifying

// the number of steps of the motor and the pins it's

// attached to

Stepper stepper(STEPS, 4, 5, 6, 7);

// the previous reading from the analog input

int previous = 0;

const int numReadings = 10;

int encoderbutton =0; //for future use

int mtcsetup =0; //for future use

int speedthreshold =31; //for future use

int wedgemin=480;

int wedgemax =520;

int readings[numReadings]; // the readings from the analog input

int index = 0; // the index of the current reading

int total = 0; // the running total

int average = 0; // the average

int averageold = 0;

int inputPin = A0;

int sensorValue = 0; // the sensor value

int sensorMin = 1023; // minimum sensor value

int sensorMax = 0; // maximum sensor value

int sweep =0;

void setup()

{

// set the speed of the motor to 30 RPMs

stepper.setSpeed(80);

// initialize all the readings to 0:

for (int thisReading = 0; thisReading < numReadings; thisReading++)

readings[thisReading] = 0;

stepper.step(-650); //sets the initial home position of the gauge

//Serial.begin (9600);

}

void loop()

{

// subtract the last reading:

total= total - readings[index];

// read from the sensor:

sweep = analogRead(inputPin);

if(sweep >= wedgemin){ //functional wedge angle, this is where the pot is when the hydrofoil is at 75 degrees

sweep = map(sweep,wedgemin,wedgemax, 214, 483); //the remapped values are representative of where the gauge's needle is.

// at 214 it is where the 'deploy' sweep transitions to the 'wedge size' position

}

else { //wedge depoly and retract. non functional angle

sweep = map(sweep, 0,wedgemin, 0,214);

}

readings[index] = sweep;

// add the reading to the total:

total= total + readings[index];

// advance to the next position in the array:

index = index + 1;

// if we're at the end of the array...

if (index >= numReadings)

// ...wrap around to the beginning:

index = 0;

// calculate the average:

average = total / numReadings;

// get the sensor value

int val = average;

if((average >= (averageold+3)) || (average <= (averageold-3))) { //reduces the amount of needle jitter by only move the stepper if the interger changes by 3 or more

// sensor reading

stepper.step(val - previous);

// remember the previous value of the sensor

previous = val;

averageold =average;

}

//Serial.print ("average: ");

//Serial.print (average);

//Serial.print (" actual: ");

//Serial.println (analogRead(inputPin));

/* //wedgeSetup below

if(mtcsetup == 1){ // record the maximum sensor value

if (sweep > wedgemax) {

wedgemax = sweep;

}

if (encoderbutton == HIGH){ // pressing the encoder button will set the wedges highest functional angle

wedgemin =sweep;

}

}

//*/

}

I hope i was clear enough.

i know the issue is in the remap portion but i just don't know an alternative to fix the sync issue. any ideas on how to correctly code for something like this?

thanks in advance,

'scott