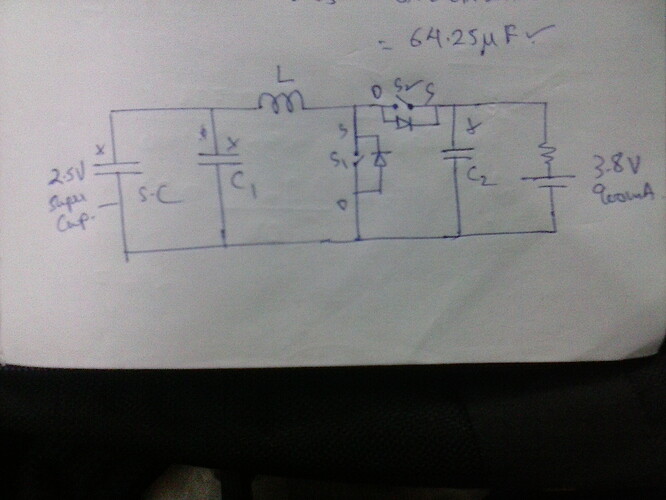

Im working on a dc-dc buck boost converter, with 2 different switching elements for bidirectional operation:

#include <PID_v1.h>

#include <math.h>

float pwPin1 = 5;

float pwPin2 = 6;

float analogPin1 = 1;

float analogPin2 = 2;

float analogPin3 = 3;

float value1 = 0;

float value2 = 0;

float boostDuty = 0;

float buckDuty = 0;

int v1 = 0;

double Input1;

double Output1;

double Setpoint1;

double Input2;

double Output2;

double Setpoint2;

double aggKp1 = 1, aggKi1 = 0.5, aggKd1 = 1; // settiing aggressive values of Kp Ki Kd for PID1

double consKp1 = 0.1, consKi1 = 0.05, consKd1 = 0.25; // settiing aggressive values of Kp Ki Kd for PID1

double aggKp2 = 1, aggKi2 = 0.5, aggKd2 = 1; // settiing aggressive values of Kp Ki Kd for PID2

double consKp2 = 0.1, consKi2 = 0.05, consKd2 = 0.25; // settiing aggressive values of Kp Ki Kd for PID2

PID myPID1(&Input1, &Output1, &Setpoint1, consKp1, consKi1, consKd1, DIRECT); //PID1

PID myPID2(&Input2, &Output2, &Setpoint2, consKp2, consKi2, consKd2, DIRECT); //PID2

void setup()

{

pinMode(pwPin1, OUTPUT); //set PWM 5 to output

pinMode(pwPin2, OUTPUT); //set PWM 6 to output

Input1 = analogRead(analogPin1); //take feedback of output in boost mode to PID1

Input2 = analogRead(analogPin2); //take feedback of output in boost mode to PID2

Setpoint1 = 777; // set point for PID1

Setpoint2 = 491; // set point for PID2

myPID1.SetMode(AUTOMATIC); // turn ON PID1

myPID2.SetMode(AUTOMATIC); //turn on PID2

TCCR0B = TCCR0B & B11111000 | B00000001; // set freq. of PWM to 62.5kHz

}

void loop()

{

TCCR0B = TCCR0B & B11111000 | B00000001;

Input1 = analogRead(analogPin1);

Input2 = analogRead(analogPin2);

v1 = analogRead(analogPin3);

double gap1 = abs(Setpoint1 - Input1); //distance away from setpoint

double gap2 = abs(Setpoint2 - Input2); //distance away from setpoint

if (gap1 < 10)

{

myPID1.SetTunings(consKp1, consKi1, consKd1);

}

else

{

myPID1.SetTunings(aggKp1, aggKi1, aggKd1);

}

if (gap2 < 10)

{

myPID2.SetTunings(consKp2, consKi2, consKd2);

}

else

{

myPID2.SetTunings(aggKp2, aggKi2, aggKd2);

}

if (v1 <= 511 && v1 > 306)

{

do // boost converter fn.

{

Input1 = analogRead(analogPin1); //read A2

boostDuty = 1 - (Input1 / 778); //calculate boost duty ratio

myPID1.Compute();

analogWrite(pwPin2, (boostDuty * 255 * Output1)); //write to D6

}

while (v1 > 306);

}

else

{

do //buck converter fn.

{

Input2 = analogRead(analogPin2);

value1 = Input2 / 4.01;

buckDuty = value1 / 202;

myPID2.Compute();

analogWrite(pwPin1, buckDuty * Output2);

}

while (v1 < 511);

v1 = analogRead(analogPin3);

if (v1 = 0)

analogWrite(pwPin1, 0);

}

}

As per value of v1 the buck mode or boost mode gets selected.Im facing the following problems:

-

The buck mode does not seem to generate a PWM??

-

Ive used 2 seperate PID fns. ...can someone please check wether ive applied correctly? especially the output statement?

-

I based the duty ration of buck & boost fn on the basic voltage eqn. for buck and boost converter...is that fine...and ive multipled it with output1 & output 2 of PID??

-

The processor is heating up??why?

-

Is the if ..else statement used for selecting boost and buck function correct???

Ive attached the power circuit diagram for your reference..

Please help have a project submission.....

Thanks & regards

Emmanuel