Hi everybody!

I allow myself to open this topic because I have a small problem which made me lose tufts of hair .. here is my problem:

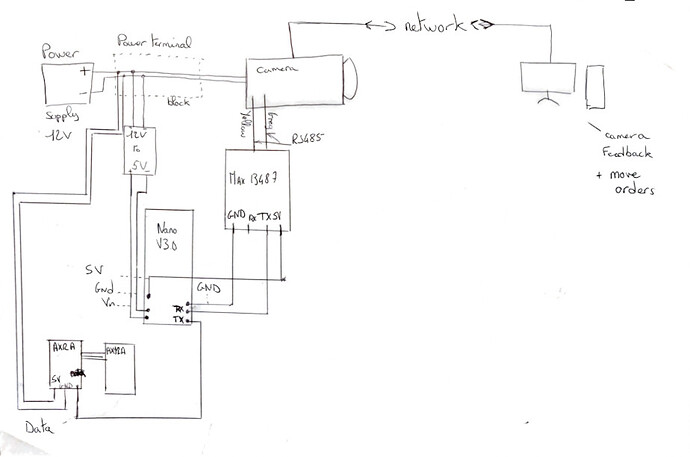

I'm on a personal project, I bought this camera 4.

To motorize it using dynamixel AX12A servomotors (to avoid shaking in the backlash of inexpensive servos and thus have a clean rendering).

For communication, I bought an RS485 to TTL module:

Here it is 2

I was able to recover and slightly modify a code which works very well, and so I managed my first version using a UNO R3 card and a "smart servo shield" from DFrobot.

my block with the arduino card and its shield being much too big by my eyes, I would therefore like to use a Nano V3.0 card.

I changed library to be able to order my servos without shield.

So I did again my connections with the nano, added a small 12-> 5V transformer for its power supply and turned everything on. Everything is at its nominal voltage, but it does not work.

I do have the TXD led of the module and TX of the card which flash at the same rate as the orders that I send from my return camera (on another PC), so I receive something.

But when I print my frame on the serial monitor, I realize that I only get empty frames

(0000000)

what bothers me is that it works great with the UNO R3 with or without shield ...

and I did not find any similar topics other than those which helped me to make my V1.

maybe a pilot problem?

Do you have any advice for me?

Thanks in advance for your time.

* module rs485 :

* -TXD (out module) sur RX carte

* _relier gnd cam au gnd IN module

*

*

*

*/

/*-----( Import needed libraries )-----*/

#include <SPI.h>

#include <ServoCds55.h>

/*-----( Declare Constants and Pin Numbers )-----*/

#define ID_Pan 1

#define ID_Tilt 2

#define RS485lTxControl 4 //RS485 Direction control

#define RS485Transmit HIGH // not needed here, the servos attached to the arduino will not transmit any data to the Pelco-D controller

#define RS485Receive LOW

#define Pin13LED 13

/*-----( Declare objects )-----*/

ServoCds55 myservo;

/*-----( Declare Variables )-----*/

byte byteReceived[7];

int byteNumber = 0;

int byteSend;

int minPulse1 = 100; // minimum servo position

int maxPulse1 = 212; // maximum servo position

int turnRate1 = 1; // servo turn rate increment (larger value, faster rate)

int minPulse2 = 138; // minimum servo position

int maxPulse2 = 178; // maximum servo position

int turnRate2 = 1; // servo turn rate increment (larger value, faster rate)

/** The Arduino will calculate these values for you **/

int centerservoPAN;

int centerservoTILT;

int pulseWidth1; // servo pulse width

int pulseWidth2; // servo pulse width

void setup() {

Serial.begin (9600);

myservo.begin ();

myservo.setVelocity(50);

centerservoPAN = maxPulse1 - ((maxPulse1 - minPulse1)/2);

centerservoTILT = maxPulse2 - ((maxPulse2 - minPulse2)/2);

pulseWidth1 = centerservoPAN;

pulseWidth2 = centerservoTILT;

Serial.println("Arduino Serial Servo Control with Pelco D");

Serial.println();

pinMode(Pin13LED, OUTPUT);

pinMode(RS485lTxControl, OUTPUT);

digitalWrite(RS485lTxControl, RS485Receive); // Init Transceiver

delay(10000);

Serial.println("initialisation des moteurs");

myservo.WritePos(ID_Pan,pulseWidth1);

myservo.WritePos(ID_Tilt,pulseWidth2);

Serial.println("ready");

}//--(end setup )---

void loop() {

// if (!Serial.available())Serial.println("pas de co");

if (Serial.available() > 0) //Look for incoming serial data from Pelco-D controller

{

byteReceived[byteNumber ++] = Serial.read(); // Read received byte

//Serial.println(byteReceived[byteNumber], DEC); // Show on Serial Monitor

delay(10);

if ( byteReceived[0] != 0xFF ) {byteNumber = 0;} // When Byte 0 isn't 0xFF (Pelco 1st Byte) reset byteNumber to 0 preventing the serial port being blocked.

}

if ( byteNumber > 6 ) // process it

{

byteNumber = 0; // ready for next time

byte data = byteReceived[3]; // read the incoming byte:

Serial.println(data, HEX); // Show on Serial Monitor

switch(data)

{

case 0x00 : break;

case 0x02 : pulseWidth1 = pulseWidth1 - turnRate1; myservo.WritePos(ID_Pan,pulseWidth1); break; // right

case 0x04 : pulseWidth1 = pulseWidth1 + turnRate1; myservo.WritePos(ID_Pan,pulseWidth1); break; // left

case 0x10 : pulseWidth2 = pulseWidth2 - turnRate1; myservo.WritePos(ID_Tilt,pulseWidth2); break; // down

case 0x08 : pulseWidth2 = pulseWidth2 + turnRate1; myservo.WritePos(ID_Tilt,pulseWidth2); break; // up

case 0x14 : pulseWidth1 = pulseWidth1 + turnRate1; myservo.WritePos(ID_Pan,pulseWidth1); pulseWidth2 = pulseWidth2 - turnRate1; myservo.WritePos(ID_Tilt,pulseWidth2); break; // left-up

case 0x12 : pulseWidth1 = pulseWidth1 - turnRate1; myservo.WritePos(ID_Pan,pulseWidth1); pulseWidth2 = pulseWidth2 - turnRate1; myservo.WritePos(ID_Tilt,pulseWidth2); break; // right-up

case 0x0C : pulseWidth1 = pulseWidth1 + turnRate1; myservo.WritePos(ID_Pan,pulseWidth1); pulseWidth2 = pulseWidth2 + turnRate1; myservo.WritePos(ID_Tilt,pulseWidth2); break; // left-down

case 0x0A : pulseWidth1 = pulseWidth1 - turnRate1; myservo.WritePos(ID_Pan,pulseWidth1); pulseWidth2 = pulseWidth2 + turnRate1; myservo.WritePos(ID_Tilt,pulseWidth2); break; // right-down

}

// stop servo pulse at min and max

if (pulseWidth1 > maxPulse1) { pulseWidth1 = maxPulse1; }

if (pulseWidth1 < minPulse1) { pulseWidth1 = minPulse1; }

// stop servo pulse at min and max

if (pulseWidth2 > maxPulse2) { pulseWidth2 = maxPulse2; }

if (pulseWidth2 < minPulse2) { pulseWidth2 = minPulse2; }

// print pulseWidth back to the Serial Monitor (uncomment to debug)

Serial.println("Servo 1: ");

Serial.println(pulseWidth1);

Serial.println(" Servo 2: ");

Serial.println(pulseWidth2);

Serial.println("degrees");

}

}````