raschemmel, you can also give Texas Instruments a "0" too. An analog "0".

I clearly stated I would not address the communications aspect since it has no relavance.

If you want to link a 10A analog PWM circuit then we can talk. The op amp circuit you linked has no relavance and once again I remind you we are discussing pwm of a motor, not communications PWM.

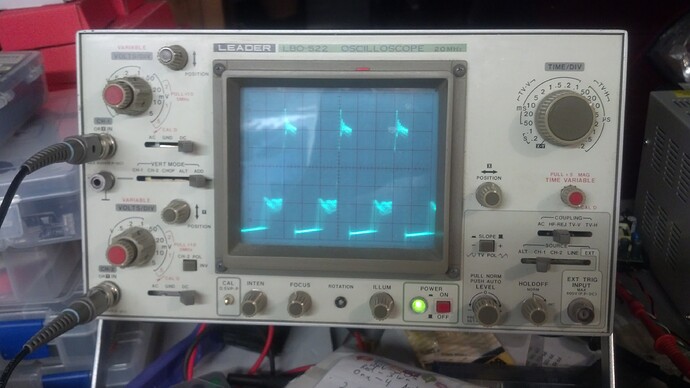

Please try to stay on topic. The OP has a 10A blower motor. Your TI communications circuit is not going to do him any good (and I said I wouldn't discuss communications). You can see the waveform on the scope, so unless you want to post a scope screenshot of a MOTOR PWM waveform that LOOKS ANALOG, you still get a "0".

The fact that you think the PWM is analog because TI's ANALOG circuits division designed a circuit that outputs PWM (again, not analog) is amusing. You need to review the definition of analog. That communications circuit is outputing PWM, which (once again) is not analog.

This circuit utilizes a triangle wave generator and

comparator to generate a pulse-width-modulated

(PWM) waveform with a duty cycle that is inversely

proportional to the input voltage. An op amp and

comparator generate a triangular waveform which is

passed to the inverting input of a second comparator.

By passing the input voltage to the non-inverting

comparator input, a PWM waveform is produced.

Negative feedback of the PWM waveform to an error

amplifier is utilized to ensure high accuracy and

linearity of the output

That circuit is an ANALOG to PWM converter.

This circuit utilizes a triangle wave generator and

comparator to generate a pulse-width-modulated

(PWM) waveform with a duty cycle that is inversely

proportional to the input voltage

Input voltage: -2 V to +2 V, dc coupled

Output: 5 V, 500 kHz PWM

Look up ANALOG. Or, better yet, look at an audio signal or an analog signal from a sensor or the voltage on a pot as you turn it.

while your at it, look up PWM.

The definition is in the name : It is a PULSE , and the WIDTH of the PULSE is MODULATED.

(it could also be +/- voltage pwm)

A PWM signal is still PWM , even when generated by analog chips, like op amps.

I guess you could ask "So why is a PULSE not ANALOG ?"

(hint: because it's a pulse ?)

@OP,

Pulse mode uses a continuous series of low speed (490Hz) 12V power pulses to regulate the blower speed

Why are you using 490 Hz instead of 16 kHz ?

// Arduino UNO DDS

#include <PWM.h>

int32_t frequency_9 = 12000; //frequency (in Hz)

int32_t frequency_3 = 16000; //frequency (in Hz)

void setup()

{

InitTimersSafe();

SetPinFrequencySafe(9, frequency_9);

SetPinFrequencySafe(3, frequency_3);

}

void loop()

{

int val = analogRead(A0);

val = map(val, 0,1023,0,100);

int dutyC =512; // Duty Cycle 0 (0%) - 1023(100%)

pwmWrite(9, dutyC / 4);

pwmWrite(3, val);

delay(30);

}

+1 no price tag

It was $95 if anyone was intereseted. (HALTED SPECIALTIES, SUNNYVALE, CA, USA)