Ignore direction of the motors(for now).

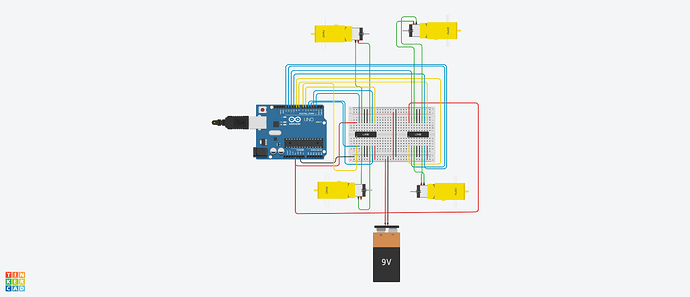

This is my connection diagram. Any and all improvements to the connections are welcome.

PS: I really cant change any of the components present here, due to material, financial and time constraints.

Bottom left motor seems to run at 210-224 rpm

Bottom right motor runs at 160-180 rpm

Top right motor runs at 210-224 rpm

Top left motor runs at 160-180 rpm

Code:

// Motor A connections

int enA = 7;

int in1 = 4;

int in2 = 5;

// Motor B connections

int enB = 6;

int in3 = 3;

int in4 = 2;

//Motor c

int enC = 9;

int in5 = 12;

int in6 = 13;

// Motor d connections

int enD = 8;

int in7 = 10;

int in8 = 11;

void setup() {

// Set all the motor control pins to outputs

pinMode(enA, OUTPUT);

pinMode(enB, OUTPUT);

pinMode(in1, OUTPUT);

pinMode(in2, OUTPUT);

pinMode(in3, OUTPUT);

pinMode(in4, OUTPUT);

pinMode(enC, OUTPUT);

pinMode(enD, OUTPUT);

pinMode(in5, OUTPUT);

pinMode(in6, OUTPUT);

pinMode(in7, OUTPUT);

pinMode(in8, OUTPUT);

// Turn off motors - Initial state

digitalWrite(in1, LOW);

digitalWrite(in2, LOW);

digitalWrite(in3, LOW);

digitalWrite(in4, LOW);

digitalWrite(in5, LOW);

digitalWrite(in6, LOW);

digitalWrite(in7, LOW);

digitalWrite(in8, LOW);

}

void loop() {

moveForward();

delay(3000);

motorOff();

delay(1000);

}

void moveForward(){

analogWrite(enA, 200);

analogWrite(enB, 200);

analogWrite(enC, 200);

analogWrite(enD, 200);

digitalWrite(in1, HIGH);

digitalWrite(in2, LOW);

digitalWrite(in3, HIGH);

digitalWrite(in4, LOW);

digitalWrite(in5, HIGH);

digitalWrite(in6, LOW);

digitalWrite(in7, HIGH);

digitalWrite(in8, LOW);

}

void motorOff(){

digitalWrite(in1, LOW);

digitalWrite(in2, LOW);

digitalWrite(in3, LOW);

digitalWrite(in4, LOW);

digitalWrite(in5, LOW);

digitalWrite(in6, LOW);

digitalWrite(in7, LOW);

digitalWrite(in8, LOW);

}

Any changes to the code are also welcome

type or paste code here

EDIT: Tried this simulation in the real world, with a raspberry pi model 4B, and the corresponding python code, Worked almost successfully(3 motors worked, i suspect the 4th one didnt receive as much current to start), and in return fried my raspberry pi.