Now that makes sense.

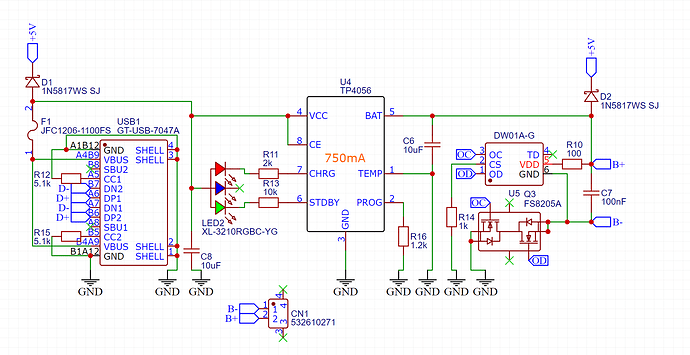

Well i figured that much, but the 'different matter' comes to light now. Using a TP4056 for charging, how do you prevent 'load-sharing' ? in other words, how do you prevent the board from draining current while the battery is being charged ? It is something to consider for safety. You have been creating a board, so i guess you thought about it, but given this kind of info, i just have to ask (check).

No, i don't use google-drive, but i would need to sing into something.

That happens. I make boards that use mosfets, If i want JLCPCB to add them to my board, i need to buy 2500 of them first up. My boards are not that successful yet.

But this is the first time you are using an ESP12-f rather than a Wemos ?

Anyway we are drifting off. (my fault) The issue must be somewhere in the automated Reset system, either in the 2 transistors responding to DTR and pulling GPIO 0 LOW while pulling RST LOW, and otherwise further upstream (so to say) in the CH340. As said, i don't use the automated reset system on my boards, but rather do the initial upload and use OTA from then on.

Ah well that is a limitation that wasn't clear to me. I guess it works with original Wemos, so it should work with your board.

Hmmm how to figure out what is going on, even with an oscilloscope, i guess you would need to monitor several pins to see if what is supposed to happen actually does.

Maybe the easiest is the sacrifice a PCB, remove the transistors, and create 2 push-buttons (or just one, i see you actually have a RST button already) to set the board into 'flash-boot-mode' manually, so at least you can confirm that the whole rest of the board works as it is supposed to.

There is also the possibility that JLCPCB or you have made a mistake with the BOM of course, The Capacitor on the RST pin might not be the correct value. If that is to big, you would have to manually reset the board every time because the DTR signal won't manage to pull the Pin LOW. For a manual reset system, it doesn't need to be there, and even for an automatic one, i think it should work without (or it is in the wrong place in the schematic and belongs to the DTR system) , so it's worth a go to remove it and / or replace it with a cap if which you know the size.

I am just throwing Ideas in there, if you can open your gerber viewer and make a screen-shot for each layer, then crop them, you can post the gerbers as pictures.