Damn, That's the way I am so crazy lazy clever.

That's not true, I am just a good guy, I want to show you a lot of information about programming, and arduino with electronics. Oh, Also, the word of Arduino is not recognized (red underlined).

Mate, I'm still doubting. About the sensor, is making me crazy, works like a charm, or just it's crazy broken.

My hygrometer says min and max very different from the sensor. But when the hot air is blowing around the inside's saloon, I can not believe how the humidity is updated in less than 4 minutes. And it's stable until the temperature changes again. That's the way I am saying I am so crazy lazy clever, but it's the problem. This is not working well, I guess even without interrupts.

Because, I need to know, now that I now that the range of measurement of the sensor, is from 0 to 100 RH %

But, just taking the difference between low measures, and knowing my hygrometer is very slow... I think, maybe a good improvement would be to use a 3V battery, instead of 1.5V. But maybe it will burn.

The true, is that my hygrometer says min 30% but it can't measure under 28%

That's the way I was confused. Because the 0% is completely relative and true.

Another problem, is that the speed of the board can read even faster than the others, if speaking about mega2560 compared to ATMEGA328P.

But, I don't have TLC555 that would make the sensor, generic. With a very complex circuit. For me, at least, very hard to read if using that small size. And as I said, I am a newbie.

What I would do?

Just, to reach the 100% tonight. Again, calculate, use the same board, telecommunicate with the server over the air,

and then, response back to the controller. Which controls the power rails of the humidifier and other altern current electronic components.

So, I will use mega 2560, which I really love as it was a present, and my first Arduino. But I had to repair it =).

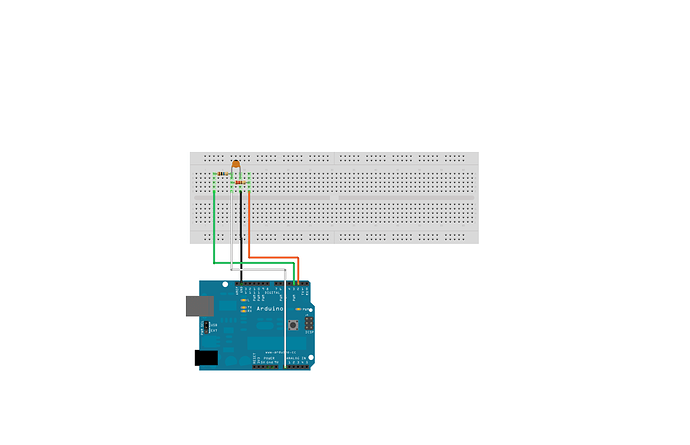

The wires are just 0.1 mm thick, and ~16cm long.

I use 2 wires, brown and green. Green is Analogue Input, brown is GND.

I used 220Ohm resistor in serie with a 1Mohm resistor in pararlel with the cap. HCH-1000 is the cap.

This humidity sensor, is crazy accurate, faster and bravely optimized. But I must recalibrate again. It's over 6% difference between "real" measurements, and between a range of 23% and 42%.

Well, I am writing a new comment every time to answer you. I am thinking always in global.

thanks for the reply, I was wondering to had news from you yesterday night, but obviously it wasn't accurate ;).

Cheers,

abel.