the simplest none-invasive way to measure current is to use a clamp, e.g. SCT-013

e.g. I use three to monitor power consumption of the property

does it have an instantaneous current output?

Does not look like it does

Your two or more topics on the same or similar subject have been merged.

Please do not duplicate your questions as doing so wastes the time and effort of the volunteers trying to help you as they are then answering the same thing in different places.

Please create one topic only for your question and choose the forum category carefully. If you have multiple questions about the same project then please ask your questions in the one topic as the answers to one question provide useful context for the others, and also you won’t have to keep explaining your project repeatedly.

Repeated duplicate posting could result in a temporary or permanent ban from the forum.

Could you take a few moments to Learn How To Use The Forum

It will help you get the best out of the forum in the future.

Thank you.

Im so sorry for this. I just thought that i could post another topic coz i have changed some of the materials that i have used in my project and I am also asking abt the code now instead of the specific materials that i can use with my project. But will delete my newer post. Sorry again.

are you asking about the SCT-013 current clamp?

if so yes - the ADC reading of the voltage output from the load resistor is related to the current flowing at that instant

to get RMS current I sample over several cycles, square the samples, take the root of the average

I have a current clamp meter and the values I get from the SCT-013 are within a couple of amps of the meter - note I am using a 100amp clamp so I was OK with 2% error

there are versions of the SCT-013 for a range of currents, e.g. 10amp to 100amp

when the heating is running at full power the load can get as high as 80amps/phase

Hi,

You really need a scope to observe the current waveform, so you know what you are dealing with.

Is this a school/college/university project?

Can you please tell us your electronics, programming, arduino, hardware experience?

Thanks... Tom... ![]()

![]()

![]()

![]()

What version of sct-013 is suggested for a 1.5 hp single phase ac motor? We have the yc90l-4 motor type for reference.

the yc90l-4 motor is rated at 1KW which at 240volts would be approximatly 4amp

I would suggest a 10 or 15amp SCT-013

a useful interface would be a ESP8266 Mains Current Sensor - Wemos which would save you buiulding a PCB to offset the voltage from the current clamp (the clamp outputs AC and the Arduino ADCs in general only accept positive DC)

Unfortunately we already bought the arduino uno r3 as our main data acq device in this project. Would it still offset the collected current from our motor if we add some resistors and capacitors with the sct sensor?

Here is a fundamental problem with your project. Your grandchildren will be able to see the motor bearings begin to fail. They are sealed ball bearings.

Detecting failed bearings with motor current is simply bs.

As above, detect dodgy bearings with vibration /over temp sensors, however, in this instance, with bearings and motor so small, probably best just to go by ear.

Works for me for the last 50 years.

hi guys can u help me with the code. i need to get the instantaneous current but the code is in rms. tya.

#include "EmonLib.h" //Include Emon Library

#define VOLT_CAL 148.7

#define CURRENT_CAL 111.1

EnergyMonitor emon1; //create an instance

void setup()

{

Serial.begin(9600);

emon1.voltage(1, VOLT_CAL, 1.7); //Voltage: input pin, calibration, phase_shift

emon1.current(0, CURRENT_CAL); //Current: input pin, calibration.

}

void loop()

{

emon1.calcVI(20,2000); //Calculate all. No.of half wavelength (crossings), time-out

float currentDraw = emon1.Irms; //extract Irms into Variable

float supplyVoltage = emon1.Vrms; //extract Vrms into Variable

Serial.print("Current: ");

Serial.println(currentDraw);

}

Hi,

Read the documentation of the library, it may tell you how.

Thanks.. Tom.. ![]()

![]()

![]()

![]()

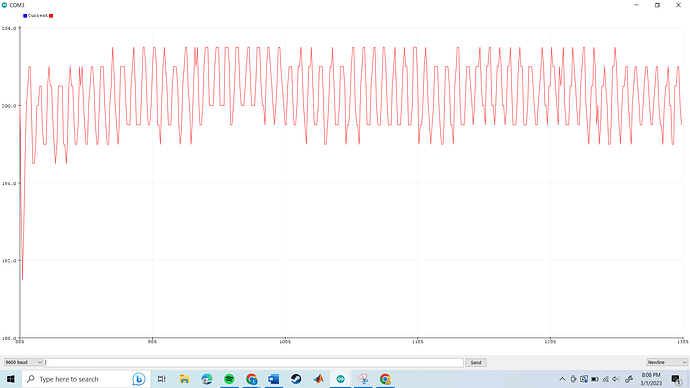

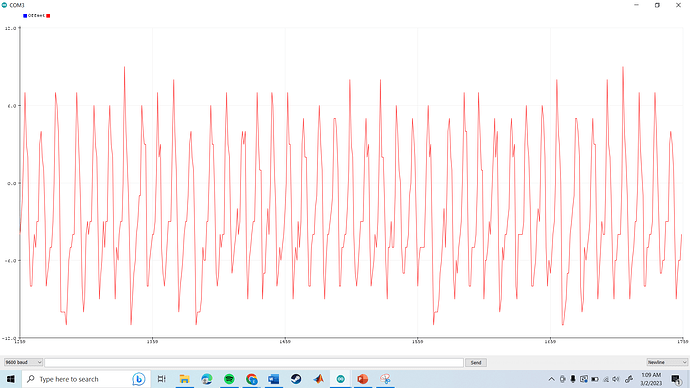

Subtract the offset (which appears to be around 201) from your data before sending it to the serial monitor.

thank you so much. do u also happen to know how to interpolate a graph so our current reading would plot out smoothly like a sine wave?

You do not have enough samples per second to give a smooth sinewave or to see any noise caused by bearing failure.

Do you have an oscilloscope?

You are going to have to be able to see what the REAL current waveform is, so you can see if your Arduino system is working properly?

What circuit and software are you using now?

Is this a school/college/university project?

If so what subject/course?

Thanks.. Tom.. ![]()

![]()

![]()

![]()

right now we are just collecting sample data using the healthy bearing of the motor. unfortunately we also don't have an oscilloscope, and we're still using the arduino uno r3 with the arduino ide. and this is actually for my bs thesis for ee. anw how long should we sample our data to see the smooth sinewave?

It is not for how long but what intervals you need to sample.

What is the frequency bandwidth you wish to detect the noise over?

bs for ee.. Bachelor of Science.. Electronic Engineering?

What year of the course?

Have you heard of the Nyquist Rate?

Google;

Nyquist Rate

The Nyquist rate or frequency is the minimum rate at which a finite bandwidth signal needs to be sampled to retain all of the information . For a bandwidth of span B, the Nyquist frequency is just 2 B. If a time series is sampled at regular time intervals dt, then the Nyquist rate is just 1/(2 dt ).

Tom.. ![]()

![]()

![]()

![]()