Hello, I am building a compression tester using an E Series Nema 34 Bipolar Stepper Motor (34HE45-6004S) and Digital Stepper Driver (DM860T). Since the motor has 2 phases, do I input 12A/36V or 6A/36V into the driver? I am planning on micro stepping.

Nema 34 (34HE45-6004S)

###Electrical Specification:

- Manufacturer Part Number: 34HE45-6004S

- Number of phase: 2

- Step Angle: 1.8deg

- Holding Torque: 8.2Nm(1161.22oz.in)

- Rated Current/phase: 6.0A

- Phase Resistance: 0.51ohms± 10%

- Inductance: 5.1mH±20%(1KHz)

Digital Stepper Driver (DM860T):

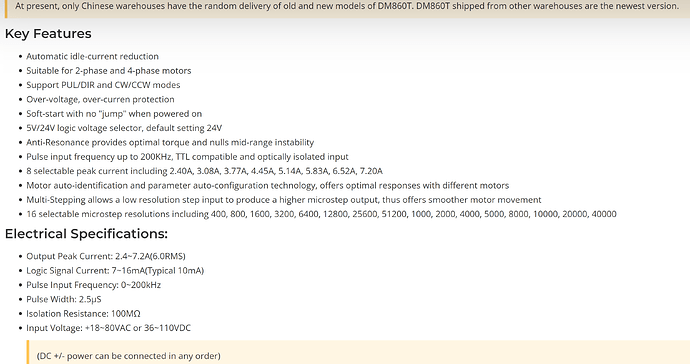

Key Features:

- Automatic idle-current reduction

- Suitable for 2-phase and 4-phase motors

- Support PUL/DIR and CW/CCW modes

- Over-voltage, over-curren protection

- Soft-start with no "jump" when powered on

- 5V/24V logic voltage selector, default setting 24V

- Anti-Resonance provides optimal torque and nulls mid-range instability

- Pulse input frequency up to 200KHz, TTL compatible and optically isolated input

- 8 selectable peak current including 2.40A, 3.08A, 3.77A, 4.45A, 5.14A, 5.83A, 6.52A, 7.20A

- Motor auto-identification and parameter auto-configuration technology, offers optimal responses with different motors

- Multi-Stepping allows a low resolution step input to produce a higher microstep output, thus offers smoother motor movement

- 16 selectable microstep resolutions including 400, 800, 1600, 3200, 6400, 12800, 25600, 51200, 1000, 2000, 4000, 5000, 8000, 10000, 20000, 40000

Electrical Specifications:

- Output Peak Current: 2.4~7.2A(6.0RMS)

- Logic Signal Current: 7~16mA(Typical 10mA)

- Pulse Input Frequency: 0~200kHz

- Pulse Width: 2.5μS

- Isolation Resistance: 100MΩ

- Input Voltage: +18~80VAC or 36~110VDC