Hi all,

I want to get the displacement information from a laser displacement sensor which is connected to an Arduino Mega Board through a ,RS485 to TTL module.

This is the RS485 to TTL module that I will be using. and the laser sensor is the XAORI LB -A100N-R4

XAORI Product Instruction Manual LB series.pdf (2.9 MB)

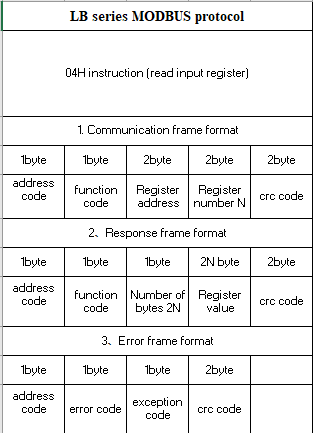

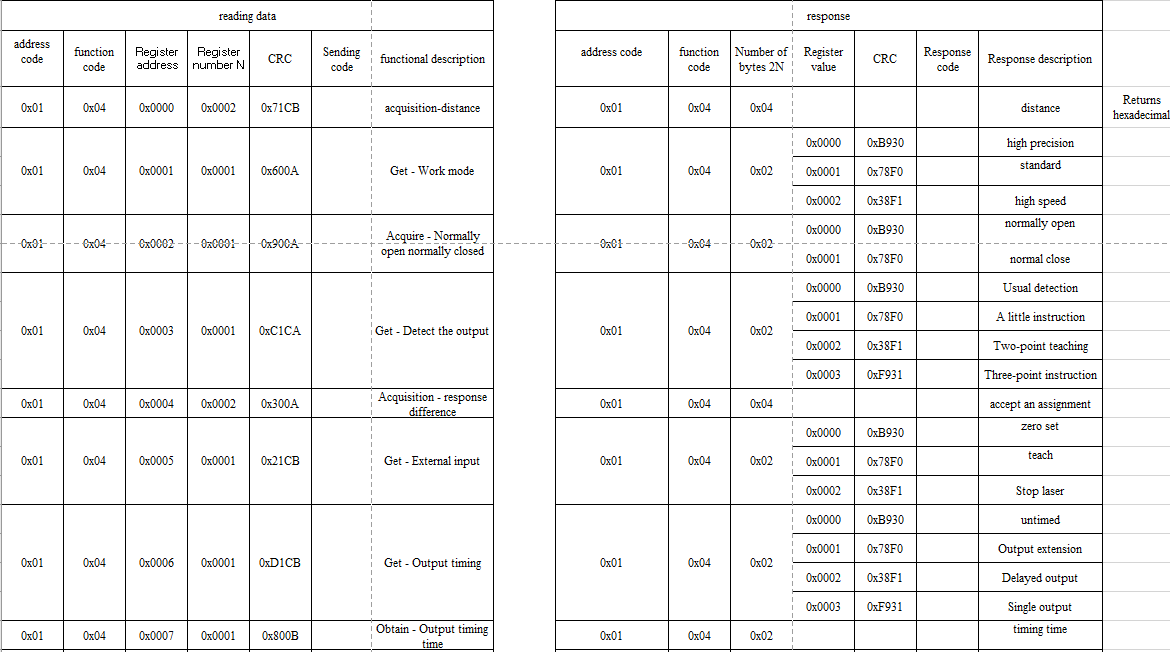

. I have documentation about the sensor's MODBUS protocol but I am unclear on how to utilize it with the libraries available as they cater towards another rs485 to ttl module that has the pins DI DE RE RO .

Can I use the Rx/Tx pins available on my ttl module with existing libraries such as Modbus Master.

How do I access the sensor data using the given documentation about addresses and function codes.

Any coding that I can refer to either create my own library or to read the data directly from an industrial sensor with an RS485 is appreciated.

Mods I do not know if this is a cross-post to my previous question or not.

Please do tell me what other information I should provide. I am currently trying to understand the examples in the SensorModbusMaster library.

/*****************************************************************************

GetValues.ino

This example writes a setting value to a holding register, reads it to confirm

the value has changed, and then reads several data values from holding registers.

The register numbers in this example happen to be for an S::CAN oxy::lyser.

*****************************************************************************/

// ---------------------------------------------------------------------------

// Include the base required libraries

// ---------------------------------------------------------------------------

#include <Arduino.h>

#include <SensorModbusMaster.h>

// ---------------------------------------------------------------------------

// Set up the sensor specific information

// ie, pin locations, addresses, calibrations and related settings

// ---------------------------------------------------------------------------

// Define the sensor's modbus address

byte modbusAddress = 0x01; // The sensor's modbus address, or SlaveID

long modbusBaudRate = 38400; // The baud rate the sensor uses

// Define pin number variables

const int sensorPwrPin = 10; // The pin sending power to the sensor

const int adapterPwrPin = 22; // The pin sending power to the RS485 adapter

const int DEREPin = 7; // The pin controlling Recieve Enable and Driver Enable

// on the RS485 adapter, if applicable (else, -1)

// Setting HIGH enables the driver (arduino) to send text

// Setting LOW enables the receiver (sensor) to send text

// Construct software serial object for Modbus

#if defined(ARDUINO_AVR_UNO)

// The Uno only has 1 hardware serial port, which is dedicated to comunication with the computer

// If using an Uno, you will be restricted to using AltSofSerial or SoftwareSerial

#include <SoftwareSerial.h>

const int SSRxPin = 10; // Recieve pin for software serial (Rx on RS485 adapter)

const int SSTxPin = 11; // Send pin for software serial (Tx on RS485 adapter)

SoftwareSerial modbusSerial(SSRxPin, SSTxPin);

#else

// This is just a assigning another name to the same port, for convienence

// Unless it is unavailable, always prefer hardware serial.

HardwareSerial* modbusSerial = &Serial1;

#endif

// Construct the modbus instance

modbusMaster modbus;

// ---------------------------------------------------------------------------

// Main setup function

// ---------------------------------------------------------------------------

void setup()

{

// Set various pins as needed

if (DEREPin >= 0)

{

pinMode(DEREPin, OUTPUT);

}

if (sensorPwrPin >= 0)

{

pinMode(sensorPwrPin, OUTPUT);

digitalWrite(sensorPwrPin, HIGH);

}

if (adapterPwrPin >= 0)

{

pinMode(adapterPwrPin, OUTPUT);

digitalWrite(adapterPwrPin, HIGH);

}

// Turn on the "main" serial port for debugging via USB Serial Monitor

Serial.begin(57600);

// Turn on your modbus serial port

#if defined(ARDUINO_AVR_UNO)

modbusSerial.begin(modbusBaudRate);

// NOTE: Software serial only supports 8N1

#else

Serial1.begin(modbusBaudRate, SERIAL_8O1);

// ^^ use this for 8 data bits - odd parity - 1 stop bit

// Serial1.begin(modbusBaudRate, SERIAL_8E1);

// ^^ use this for 8 data bits - even parity - 1 stop bit

// Serial1.begin(modbusBaudRate, SERIAL_8N2);

// ^^ use this for 8 data bits - no parity - 2 stop bits

// Serial1.begin(modbusBaudRate);

// ^^ use this for 8 data bits - no parity - 1 stop bits

// Despite being technically "non-compliant" with the modbus specifications

// 8N1 parity is very common.

#endif

// Turn on debugging, if desired

// modbus.setDebugStream(&Serial);

// Start the modbus instance

modbus.begin(modbusAddress, modbusSerial, DEREPin);

// Write to a holding register

// In this case, we are changing the output units of a dissolved oxygen sensor

Serial.println("Setting DO units to ppm");

modbus.int16ToRegister(0x01, 1, bigEndian);

// Verify that the register changed

// 0x03 = holding register

// only holding registers are writeable

int16_t doUnitMode = modbus.int16FromRegister(0x03, 0x01, bigEndian);

Serial.print("Current unit mode is ");

Serial.println(doUnitMode);

}

// ---------------------------------------------------------------------------

// Main setup function

// ---------------------------------------------------------------------------

void loop()

{

// Get data values from read-only input registers (0x04)

// Just for show, we will do the exact same thing 2 ways

// All values will be read as bigEndian

// Some variables to hold results

uint16_t deviceStatus = 0;

int16_t doPPM = 0;

uint16_t temperature = 0;

// Method 1:

// Get three values one at a time from 3 different registers.

// This code is easier to follow, but it requires more back-and-forth between

// the Arduino and the sensor so it is a little "slower".

deviceStatus = modbus.uint16FromRegister(0x04, 0x00, bigEndian);

doPPM = modbus.int16FromRegister(0x04, 0x01, bigEndian);

temperature = modbus.uint16FromRegister(0x04, 0x02, bigEndian);

// Print results

Serial.print("Device Status:");

Serial.println(deviceStatus);

Serial.print("Dissolved Oxygen in ppm:");

Serial.println(doPPM);

Serial.print("Temperature in °C:");

Serial.println(temperature);

Serial.println();

// Method 2:

// Read all three registers at once and parse the values from the response.

// This is faster, especially when getting many readings, but it's trickier to

// write and understand the code.

bool success = modbus.getRegisters(0x04, 0x00, 3);

// ^ This gets the values and stores them in an internal "frame" with the hex values of the response

if (success)

{

deviceStatus = modbus.uint16FromFrame(bigEndian, 3);

// ^ The first data value is at position 3 in the modbus response frame

// 0 = modbus address, 1 = modbus method, 2 = # registers returned, 3 = 1st value returned

doPPM = modbus.int16FromFrame(bigEndian, 5);

// ^ The next data value is at position 5 since each register occupies 2 places

temperature = modbus.uint16FromFrame(bigEndian, 7);

}

// Print results

Serial.print("Device Status:");

Serial.println(deviceStatus);

Serial.print("Dissolved Oxygen in ppm:");

Serial.println(doPPM);

Serial.print("Temperature in °C:");

Serial.println(temperature);

Serial.println();

}