That looks fine to me.

This is not something I am expert in, others here might want to comment on what I say, the ground plane is not just there to provide a convenient connection for everything, it also provides a low impedance path for ground. Note 'ground' does not equal negative, a common misunderstanding with beginners. Ground is often connected to negative but can just as easily be the positive of the supply or the middle, for example with a -15V, 0V +15V supply often used for analogue audio. Anyway, I digress. Having a plane provides a low impedance path for signals and power, much better than a track does. It also provides some level of noise shielding and it provides for high frequencies to have a return path that corresponds to the route of the track that carries the signal (which you don't need to worry about for the frequencies you are working with). There is a general rule in electrical circuits that you need to keep the current in both directions in adjacent wires to minimise noise pick up. A cable with all the wires bound together isn't just neat and tidy it also allows the signal and it's return to be kept together, which is essential for noise reduction. A ground plane does the same on a PCB because each track will be adjacent to the ground wherever it goes. As for a supply plane on the other side, I think the same argument applies, but I defer to the knowledge of others if someone wants to comment.

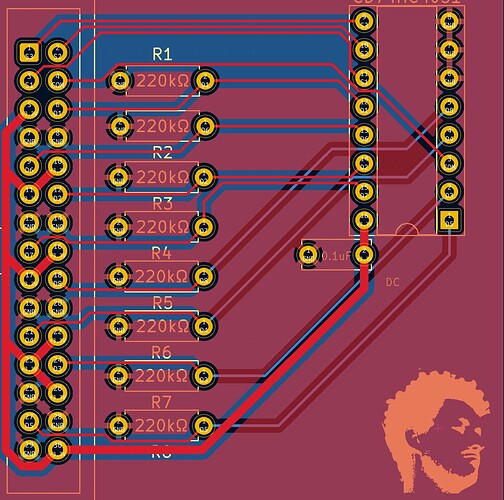

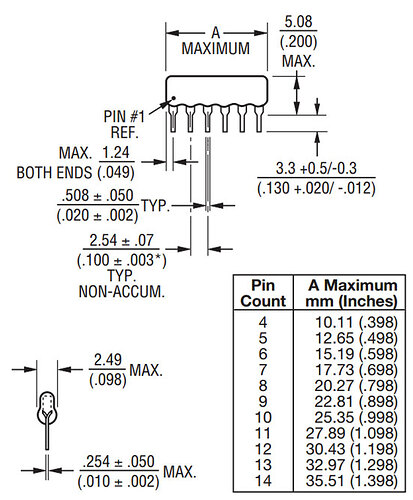

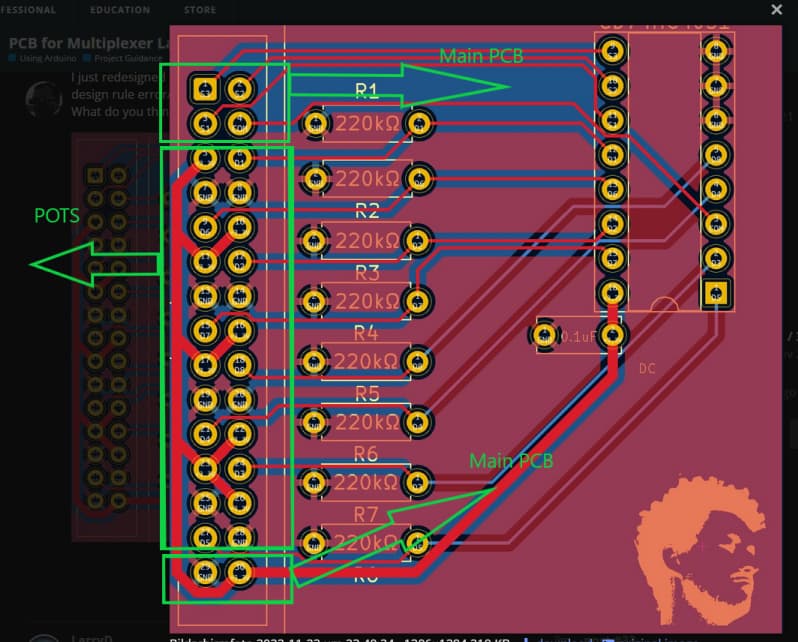

So, to translate the general comment above into something practical for your project, although the frequencies you are dealing with are low (varying voltage from adjusting a pot), the noise frequencies also have to be dealt with, and these are higher. Your circuit needs to minimise noise pick up. You need to consider the wider context of how it will be connected to its 8 pots, how it will be connected to power and how it will be connected to whatever micro-controller / Arduino you are using. The 2 connectors @6v6gt suggested makes sense. The wires to the pots should in in one cable, neatly routed and with the wires broken out to the pots as they go past. I suggest a 10 way connector and cable, that's 8 signals, 0V and +3V3. It should look neat when completed, not just for aesthetic reasons but because neat generally translates to low noise pick up.

As others have said, the capacitor on pin 16 should be 0μ1 ceramic for decoupling of the power to the chip.

Mike's advice on the input filter is good, if you have a problem with unstable readings on the input to your A2D then deal with that in software. I would expect them to vary by at least plus and minus 1 anyway, however carefully you design the electronics.