Hi everyone,

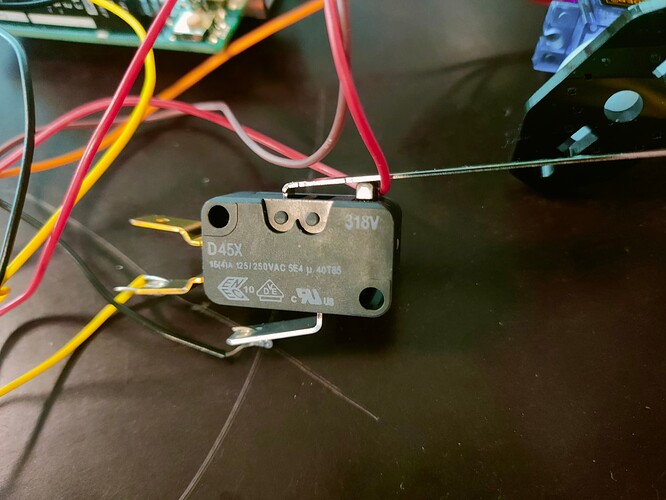

I am currently trying to program a servo motor to rotate clockwise, counter clockwise and stop when it hits a limit switch. I have got it to rotate clockwise and counter clockwise but cannot figure out how to stop it when it hits the limit switch. I also have to program a stop button but can only seem to get the servo to stop at 58 rather than stop it in its current position. I have attached my code below.

Any help would be much appreciated.

Thanks

CODE:

#include <Servo.h>

Servo myservo; // create servo object to control a servo

// twelve servo objects can be created on most boards

int servoPin = 9;// this pin must be of those with PWM ~

#define STOPpin 3 // push button pin for STOP

#define CWpin 2 // push button for CW

#define CCWpin 4 // push button for CCW

int sc[]={180, 58, 0};// servo commands are in order

//CCW, STOP,CW

String scText[]={"CCW","Stop","CW"};// define texts for 3 action

int statusText;

int CWBS, CCWBS, SBS;

//CW button status (CWBS)

//CCW button status (CCWBS)

//stop button status (SBS)

void setup() {

Serial.begin(9600);

pinMode(STOPpin,INPUT_PULLUP);// set pin for push button STOP

pinMode(CCWpin,INPUT_PULLUP);// set pin for push button CCW

pinMode(CWpin,INPUT_PULLUP);// set pin for push button CW

myservo.attach(servoPin); // attaches the servo on pin 9 to the servo object

myservo.write(sc[1]);// send STOP command

statusText=1;// initial value is STOP

}

void loop() {

CCWBS = digitalRead(CCWpin);// read status of button CCW

SBS = digitalRead(STOPpin);// read status of button STOP

CWBS = digitalRead(CWpin);// read status of button CW

if(CCWBS ==LOW)

{

servoCommand(0);

}else if(SBS ==LOW)

{

servoCommand(1);

}else if(CWBS ==LOW)

{

servoCommand(2);

}

Serial.println(scText[statusText]);

delay(50);

}// loop

void servoCommand(int n)

{

statusText = n;

myservo.write(sc[n]);

Serial.print("Going to ");

Serial.print(scText[n]);

Serial.print( "(");

Serial.print(sc[n]);

Serial.println(")");

}