Several years ago I worked on a horticulture hobby project (a grow light) to maximize plant growth efficiently using electronics and also Arduino. I now decided to share it here. Although a website and some trademarks are mentioned that is only for fun and not anything else. This is completely a hobby project and not business.

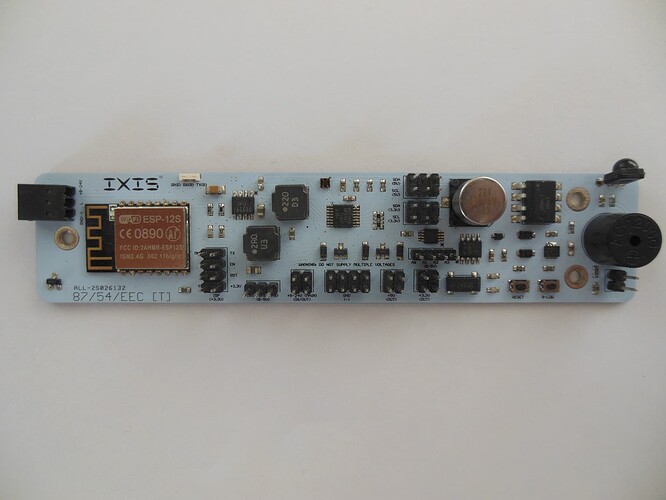

To have some control I decided to design and build a board which I named IXIS.

The (10-15 USD) board (made to sit on top of a supply) features (from left to right on the board):

- Up to 24V input, outputting 5V and 3.3V

- The fully occupied ESP8266 as the brains for the operation with a tiny indication LED.

- A small temperature sensing IC.

- Then you can see the 3.3V/5V voltage regulator with some output pins.

- A digital light sensor measuring environmental LUX values.

- Protection zener diodes for each voltage level.

- The 3.3V to 5V level shifter.

- Two I2C pin banks for 3.3V and 5V level reading.

- An IC for more analog to digital conversion to read analog sensors.

- The RTC with capacitor.

- An optocoupler driving a pin for switching and a buzzer.

- Then the IR part for remote input.

Also I designed and build a (10-15 USD) 24V constant current (adjustable between 100-1000mA) LED board to feed the plants what they need, this I named the AURA-X which features the correct light spectrum:

Plants require 450nm, 680nm and 720nm light to grow well. I cheated a bit by implementing a low K value white led to get the IR light required, this also complements the spectrum.

The system is powered by a 24V supply and put together like this:

To test the behaviour of PCBs in relation to the LEDs in terms of heat I designed this 3Oz board which keeps the LED junction temperature below the allowed value of about 130 Degrees Celsius at 350mA constantly supplied (much better performance than aluminium clad and for such a small board):

The LEDs are driven with an algorithm on the pulse. This works as follows:

- Plants have an optimum dark period at a minimum of 200 microseconds, absolutely no less.

- They can only grow for 45 minutes efficiently, then they need a minimal 9 minute rest.

- Depending on the LED board and the distance to the plant you provide a pulse for some duration (anywhere between 1 to about 200 microseconds is optimum).

- This runs around the clock and makes plants grow in a hurry. The system was tested with around the clock (24h continues) cycles in absolute darkness. It can be tuned down during the day or adjusted to rhythms should one require those (for specific plant types and/or required behaviour).

Another component I made (no pictures sorry) is a power distribution, pulse forwarding and pulse generating board. This is the analog approach to the IXIS. It features some OPAMP circuits providing the algorithm around the clock. The pulse is adjusted for environmental light automatically.

Two days in a row growing basil, these are only small plants, still relatively far away from the lights on the prototype AURA-X boards featuring older generation LEDs on 1Oz:

Eventually this system produced leafs with a weight of about 2 grams each which tasted great.

You can grow small fruit trees, regular plants, herbs or vegetables this way. They will function normally in case they are transplanted out into regular sunshine.

All of it was made using only ROHS quality components down to the solder and with a design build to last many years. Power supplies in this setup are easy to switch-out should they fail.

These first prototypes have been running for years without any failures. And using very little energy.

You could make something basic using a (adjustable) 12V power supply with things like:

I would recommend to change out the cheap COB LEDs seen above for something better (LUMILEDS) from Mouser but these are expensive and possibly use a higher voltage. When using the cheaper COBs as above some heat conductive paste between the COBs and a heatsink is needed. Or solder the slightly more expensive COBs to a custom PCB design (as they are SMD and have their contacts on the bottom). You could add materials to drive the COBs with constant current which is better than a voltage only. These cheaper COBs cost a few USD each and I only bought them to see if I could keep them cool at all and if the specification is correct.

Building SMD designs yourself at home I do not really recommend if you lack the equipment.

If you are really interested in the schematics or the board designs just let me know but for now I leave them out.

Currently I am working on ways to forward a pulse through the air without wires for use in larger open areas. When all the LEDs do not fire the pulse at the same time then light pollution occurs in the dark period of the plant resulting in reduced growth.

It is all based on science. This project was finished several years ago already but due to circumstances I could not work on it very much.

Thanks for reading my post.