Someone please correct me if I'm wrong here since I'm not the best with AC circuits, but these motors look to be industrial 3-phase motors.

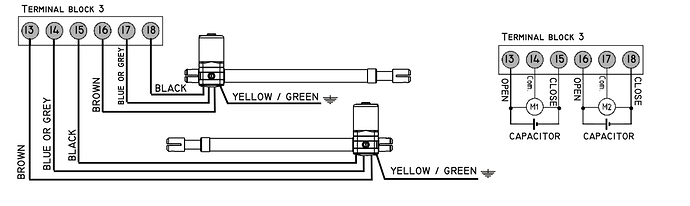

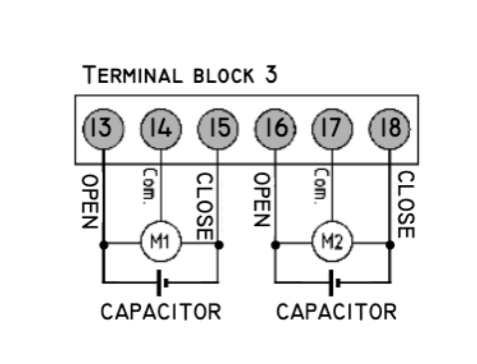

I've done a little wiring with "208-230v 3-phase" -- single-phase usually just has 2 wires to the motor, while 3-phase has 3 wires, which is what I'm seeing here.

It IS VERY possible to control with an arduino, but you may need to get rid of ALL the electronics and start with JUST the motors. If I remember correctly, on a 230 3-phase, you will get 110v-120v on each leg of the motor (while running), if you put a voltmeter between the leg (probably labelled T1, T2, and T3 on the motor) and to "ground" (one leg may be HIGHER voltage than the other 2 -- it's called the "wild leg").

To reverse a 3-phase motor, ANY TWO LEGS are swapped and it runs the opposite direction. In this set-up you would have a "common" leg but that is a bad use of the word "common." I think, for this setup, it is just the leg that is NOT switched when the motor is reversed. --- looking at the diagram, this looks like what they are doing.

Assuming this is the case, then you would be best served to to get what is called a "variable frequency drive" (also called a "VFD") and use the arduino to control it (VFD must be capable of being externally controlled -- the inexpensive ones are ONLY controlled by their own buttons). See the one that would work for this project here, assuming your motors are less than 2HP (1.5kW) each:

Variable Frequency Drive, or "VFD"

The above is "programmable" and will accept external control. You need one that will allow you to attach an "external switch" or potentiometer - this is VERY common in the industrial world, you just need to know what VFD to look for.

I don't want to give a bunch of USELESS information if your motors are NOT 3-phase, but if they are - your solution will cost $200-$300. I'll be happy to help explain the use of this "Variable Frequency Drive" and there is MUCH information on the internet about using an arduino to control a VFD, but...

I need to know if these are 3-phase motors. The "VFD" CAN have single-phase input and 3-phase output to the motors, so if your gate is attached to "single-phase" the original controller may have been using this conversion method already -- the gates may be less expensive to manufacture this way because 3-phase motors are generally less expensive and easier to control than single-phase motors.

You can use just one VFD to control both motors - as long as they are doing the same thing and in your case, it looks like they are.

edit: spelling