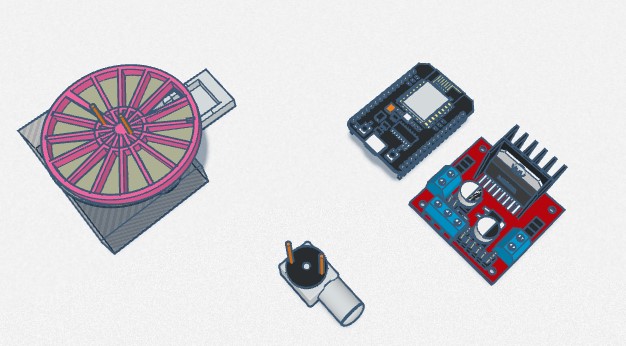

Here is my update for the project as promised. I ve decided to go with the DRV8825 Motor Driver, Nema 17 Stepper Motor, 7805 voltage regulator, DS3231 Clock module, 10 uF Cap on Volt Reg., 100uF Cap on Power 12V 2 Amps., red colored led, 10k resistor on button, and for the processing module I am using a NodeMCU 32S Dev Board. Attached is the schematics and code.

- 1st problem - Led fails to light when triggered at time period designated in code.

- 2nd problem - Nema 17 hums until called on and gets very hot.

Please see the code and the schematics for reference.

Thank you

John

#include <Arduino.h>

#include <LiquidCrystal_I2C.h> // For LCD

#include <RTClib.h> // For RTC DS3231

#include <DRV8825.h> // For Stepper Driver

#define setStepsPerRevolution 100

LiquidCrystal_I2C lcd(0x27,16,2); // Create LCD with I2C address 0x27, 16 characters per line, 2 lines

RTC_DS3231 rtc; // Create RTC for the DS3231 RTC module

//time settings for pill dispensing at 6am

int Hr = 6;

int Min = 0;

int Sec = 0;

const int dirPin = 18; // Pins 16, 17, 18 and 19 perminetly set to (ledPin, button, dirPin and stepPin)

const int stepPin = 19;

const int button = 17;

const int ledPin = 16;

//int buttonStateTwo = 0; // Sets buttonTwo off at initial state

int buttonState = 0; // Sets button off at initial state

// Minimum and maximum values structure for each input.

typedef struct minMax_t {

int minimum;

int maximum;

};

/*

Function to validate user input.

Returns TRUE if value in range, FALSE otherwise.

*/

bool checkInput(const int value, const minMax_t minMax) {

if ((value >= minMax.minimum) &&

(value <= minMax.maximum))

return true;

Serial.print(value);

Serial.print(" is out of range ");

Serial.print(minMax.minimum);

Serial.print(" - ");

Serial.println(minMax.maximum);

return false;

}

/*

Function to update RTC time using user input using "u" in serial input.

*////////////////////////////////////////////////////////////////////////////////////////////////////////

void updateRTC()

{

lcd.clear();

lcd.setCursor(0, 0);

lcd.print("Edit Mode...");

// Prompts for user input at "u" call. Sets paramaters for time.

const char txt[6][15] = {

"year [4-digit]", "month [1~12]", "day [1~31]",

"hours [0~23]", "minutes [0~59]", "seconds [0~59]"

};

// Define limits of user inputs.

const minMax_t minMax[] = {

{2000, 9999}, // Year

{1, 12}, // Month

{1, 31}, // Day

{0, 23}, // Hours

{0, 59}, // Minutes

{0, 59}, // Seconds

};

String str = "";

long newDate[6];

DateTime newDateTime;

// The outer loop. Goes around and around until we get a valid

// date and time. Thats all 6 inputs valid. It does not validate

// February and/or leap years - it doesn't have to DateTime.isValid()

// does that for us.

while (1) {

while (Serial.available()) {

Serial.read(); // Clear serial buffer

}

// We have 6 different user inputs to capture.

for (int i = 0; i < 6; i++) {

// This loop exits when one user input is valid in

// as far as being numeric and in range, sort of.

// Leap years and month end dates are validated later

// when we have the complete date and time.

while (1) {

Serial.print("Enter ");

Serial.print(txt[i]);

Serial.print(" (or -1 to abort) : ");

while (!Serial.available()) {

; // Wait for user input

}

str = Serial.readString(); // Read user input

// The actual value depends on the line ending configured in

// the Serial Monitor. The configured line end character(s)

// are part of the input string!

// If the value is -1, then we abort the clock change

// completely and bale out of this function.

if ((str == "-1") || (str == "-1\n") ||

(str == "-1\r") || (str == "-1\r\n")) {

Serial.println("\nABORTED");

return;

}

newDate[i] = str.toInt(); // Convert user input to number and save to array

// Validate input is in range, exit this inner while() loop

// if so, otherwise, lets go round again.

if (checkInput(newDate[i], minMax[i]))

break;

}

Serial.println(newDate[i]); // Show user their input

}

newDateTime = DateTime(newDate[0], newDate[1], newDate[2], newDate[3], newDate[4], newDate[5]);

if (newDateTime.isValid())

break;

Serial.println("Date/time entered was invalid, please try again.");

}

// Update RTC as we have a valid date & time.

rtc.adjust(newDateTime);

Serial.println("RTC Updated!");

}

// Function to update LCD text

void updateLCD()

{

// Get time and date from RTC.

DateTime rtcTime = rtc.now();

/*

Buffers to format the date and time (on separate lines of the LCD)

If either "AP" or "ap" is used, the "hh" specifier uses 12-hour mode

(range: 01--12). Otherwise it works in 24-hour mode (range: 00--23).

The specifiers within _buffer_ will be overwritten with the appropriate

values from the DateTime. Any characters not belonging to one of the

above specifiers are left as-is.

*/

char dateBuffer[] = "DD MMM hh:mm";

//char timeBuffer[] = "hh:mm:ss AP"; //12 hour with Am Pm settings

// char timeBuffer[] = "hh:mm:ss"; //24 hour

// char hoursBuffer[] = "hh";

//char minsBuffer[] = "mm";

//move LCD cursor to top left

lcd.setCursor(2, 0);

lcd.print(rtcTime.toString(dateBuffer));

//Then after above move LCD cursor to top line,

//far left position.

// lcd.setCursor(5, 0);

// lcd.print("Time");

//lcd.setCursor(4, 1);

//lcd.print(rtcTime.toString(timeBuffer));

}

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////

void setup()

{

Serial.begin(9600);

lcd.display();

lcd.init();

lcd.clear();

lcd.backlight();

//lcd.noBacklight(); // Switch-off lcd backlight

rtc.begin(); // Initialize RTC module.

pinMode(stepPin, OUTPUT);

// set both step and dir pins to output from board

pinMode(dirPin, OUTPUT);

// set led pin to output

pinMode(ledPin, OUTPUT);

// set button pin to INPUT

pinMode(button, INPUT);

// set buttonTwo pin to INPUT

//pinMode(buttonTwo, INPUT);

}

///// Begin Dispensing

void rotate() {

// Set motor direction clockwise

digitalWrite(dirPin, HIGH);

// Spin motor

for (int i = 0; i < setStepsPerRevolution; i++) {

digitalWrite(stepPin, HIGH);

delayMicroseconds(1000);

digitalWrite(stepPin, LOW);

delayMicroseconds(1000);

}

delay(1000); // Wait a second

}

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////

void loop()

{

// Get time and date from RTC.

DateTime rtcTime = rtc.now();

// read the state of the pushbutton value:

buttonState = digitalRead(button);

//buttonStateTwo = digitalRead(buttonTwo);

updateLCD();

if (rtcTime.hour() == Hr && rtcTime.minute() == Min && rtcTime.second() == Sec){

lcd.clear();

lcd.setCursor(0,1);

lcd.print("Pills Ready");

digitalWrite(ledPin,HIGH);

rotate(); //start stepper

}

if (buttonState == HIGH) {

lcd.backlight(); // Switch-on lcd backlight

lcd.clear();

digitalWrite(ledPin, LOW);

lcd.setCursor(0, 1);

lcd.print("Pills Taken");

}

// Press button when pills taken. Check if the pushbutton is pressed.

// If it is, the buttonState is HIGH:

if (Serial.available()) {

char input = Serial.read();

if (input == 'u') updateRTC();

}

}