Could those with a bit of time please go through my sketch and give me some guidance as to what i could do better and where things could be a bit more streamline.

Given that I have only been writing code for two weeks without a single class, feel free to go easy on me...

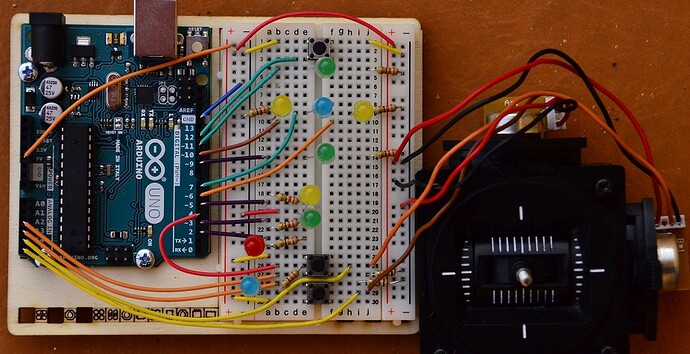

I hope a photo of the breadboard layout will suffice

//Joystick Inputs:

const int updownInPin = A4; // Analog input pin that "up down stick" is attached to

const int leftrightInPin = A5; // Analog input pin that the "left right stick" is attached to

const int estopInPin = A2; // Activate and deactivate the "E-Stop"

const int lockoutInPin = A3; // Activate and deactivate the "E-Stop"

const int faultInPin = 12; // Reset any Faults on the drive may encounter

//Signal Outputs to Vairiable Speed Drives:

const int upOutPin = 6; // UP LED or Clock Wise for drive A

const int downOutPin = 10; // DOWN LED or Counter Clock Wise for drive A

const int leftOutPin = 11; // LEFT LED or Clock Wise for drive B

const int rightOutPin = 9; // RIGHT LED or Counter Clock Wise for drive B

const int faultOutPin = 4; // Fault Reset

const int estopOutPin = 2; // Emergency Stop

//PWM Outputs to Drives:

const int updownOutPin = 5; // Analog input pin that "Up Down JStick" is attached to

const int leftrightOutPin = 3; // Analog input pin that "Left Right JStick" is attached to

//for information only

const int centreOutPin = 7;

int updownJSValue = 0; // value read from the "up down Joy Stick"

int leftrightJSValue = 0; // value read from the "left right Joy Stick"

int updownoutputValue = 0; // value output to the PWM (analog out)

int leftrightoutputValue = 0; // value output to the PWM (analog out)

int estopState = 0;

int lockoutState = 0;

int faultState = 0;

void setup() {

Serial.begin(9600);

pinMode(2, OUTPUT);

pinMode(3, OUTPUT);

pinMode(4, OUTPUT);

pinMode(5, OUTPUT);

pinMode(6, OUTPUT);

pinMode(7, OUTPUT);

pinMode(9, OUTPUT);

pinMode(10, OUTPUT);

pinMode(11, OUTPUT);

pinMode(12, INPUT_PULLUP);

pinMode(A2, INPUT);

pinMode(A3, INPUT);

pinMode(A4, INPUT);

pinMode(A5, INPUT);

}

void loop() {

//Fault reset:

faultState = digitalRead (faultInPin);

if (faultState == LOW){

digitalWrite (faultOutPin, HIGH);

}

else {

digitalWrite (faultOutPin, LOW);

}

// E-Stop and push botton Lock Out Feature

estopState = digitalRead (estopInPin);

lockoutState = digitalRead (lockoutInPin);

if (estopState == HIGH && lockoutState == HIGH){

analogWrite (estopOutPin, LOW);

updownJSValue = analogRead(updownInPin);

leftrightJSValue = analogRead(leftrightInPin);

//Signal for UP to go HIGH:

if (updownJSValue >=10 && updownJSValue <=508){

digitalWrite (upOutPin, HIGH);

updownoutputValue = map(updownJSValue, 507, 100, 0, 255);

analogWrite (updownOutPin, updownoutputValue);

}

else{

digitalWrite (upOutPin, LOW);

}

//Signal for LEFT to go HIGH:

if (leftrightJSValue >=10 && leftrightJSValue <=508){

digitalWrite (leftOutPin, HIGH);

leftrightoutputValue = map(leftrightJSValue, 507, 100, 0, 255);

analogWrite (leftrightOutPin, leftrightoutputValue);

}

else{

digitalWrite (leftOutPin, LOW);

}

//Signal for DOWN to go HIGH:

if (updownJSValue >=517 && updownJSValue <1013){

digitalWrite (downOutPin, HIGH);

updownoutputValue = map(updownJSValue, 518, 900, 0, 255);

analogWrite (updownOutPin, updownoutputValue);

}

else{

digitalWrite (downOutPin, LOW);

}

//Signal for RIGHT to go HIGH:

if (leftrightJSValue >=517 && leftrightJSValue <=1013){

digitalWrite (rightOutPin, HIGH);

leftrightoutputValue = map(leftrightJSValue, 508, 900, 0, 255);

analogWrite (leftrightOutPin, leftrightoutputValue);

}

else{

digitalWrite (rightOutPin, LOW);

}

//Indidcation Joystick is in Centre Position

if (updownJSValue >508 && updownJSValue <517) {

digitalWrite (centreOutPin, HIGH);

}

else if (leftrightJSValue >508 && leftrightJSValue <517) {

digitalWrite (centreOutPin, HIGH);

}

else{

digitalWrite (centreOutPin, LOW);

}

}

else {

analogWrite (updownOutPin, 0);

analogWrite (leftrightOutPin, 0);

digitalWrite (estopOutPin, HIGH);

digitalWrite (centreOutPin, HIGH);

digitalWrite (upOutPin, LOW);

digitalWrite (downOutPin, LOW);

digitalWrite (leftOutPin, LOW);

digitalWrite (rightOutPin, LOW);

}

Serial.print(" U D PWM = " );

Serial.println(updownoutputValue);

Serial.print("U D JoyS = " );

Serial.println(updownJSValue);

Serial.print(" L R PWM = " );

Serial.println(leftrightoutputValue);

Serial.print("L R JoyS = " );

Serial.println(leftrightJSValue);

Serial.print(" E-Stop = " );

Serial.println(estopState);

Serial.print("Lock Out = " );

Serial.println(lockoutState);

Serial.println();

delay(10);

}