If you do not have access to a CNC machine, you can manually drill accurate ‘Project Panels’ by following this discussion.

Plastic panels are best drilled manually using ‘Step Bits’ as they do not auger into the panel as regular bits do.

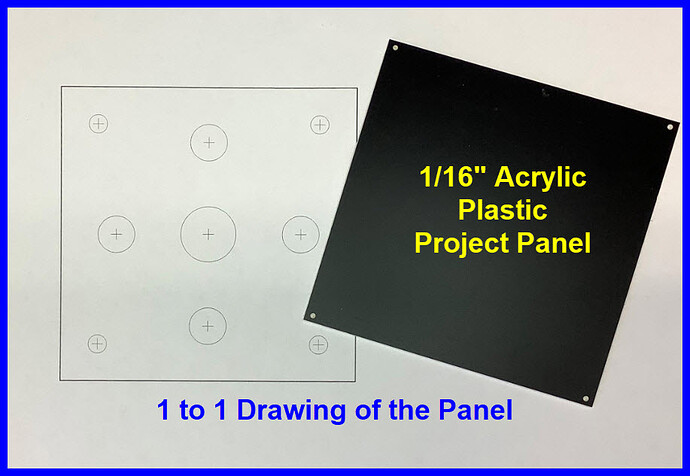

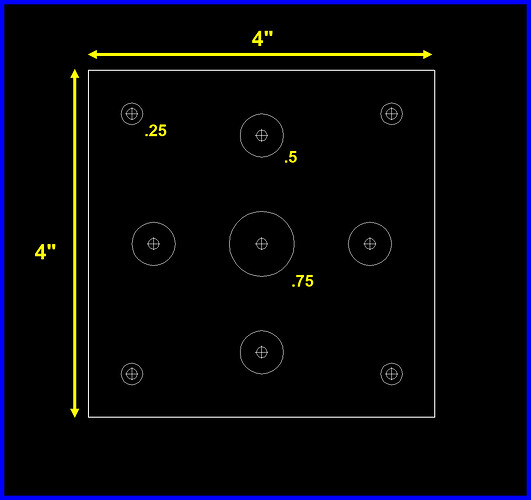

Using your favourite template drawing software, make a 1:1 layout of your panel.

Print the template on ‘Sticky Backed’ label paper. (Regular paper may be used and attached with tape.)

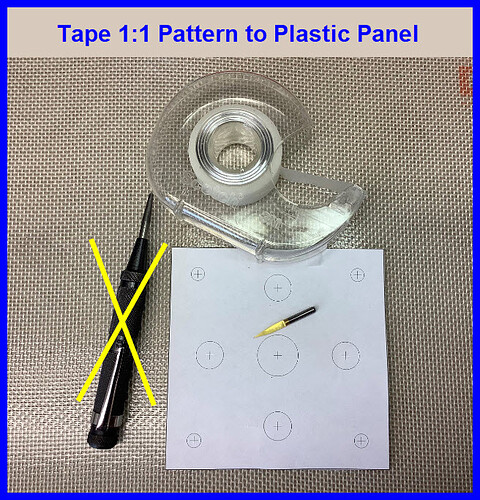

Attach the template to the plastic panel.

You can avoid center punching holes by using a ‘D’ (engraving) bit to mark hole centers.

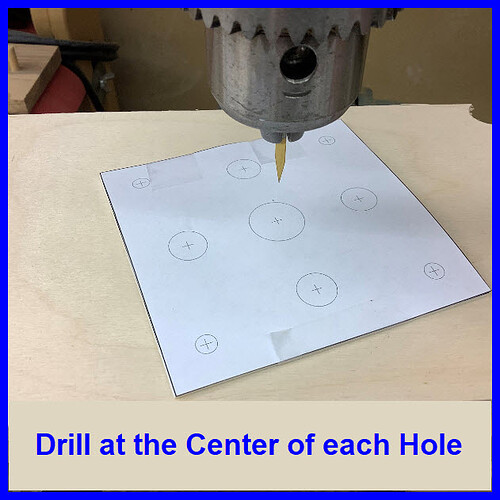

Use the pinpoint ‘D’ bit to make a 1/8” hole at the center of each template hole.

These engraving bits are made of Carbide so be careful as they break easily; these are very sharp!

Tune hole centers with a file before progressing further.

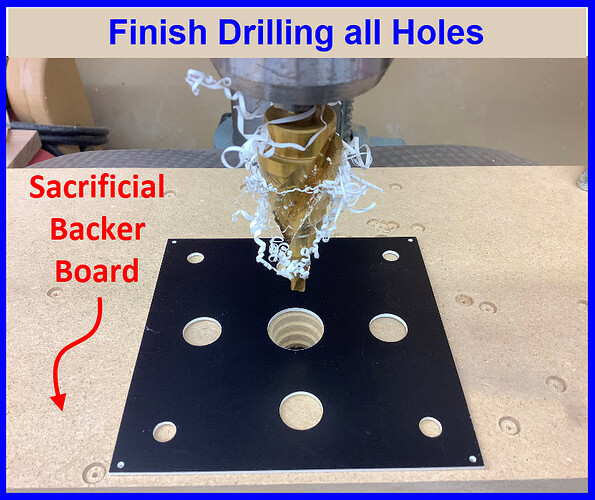

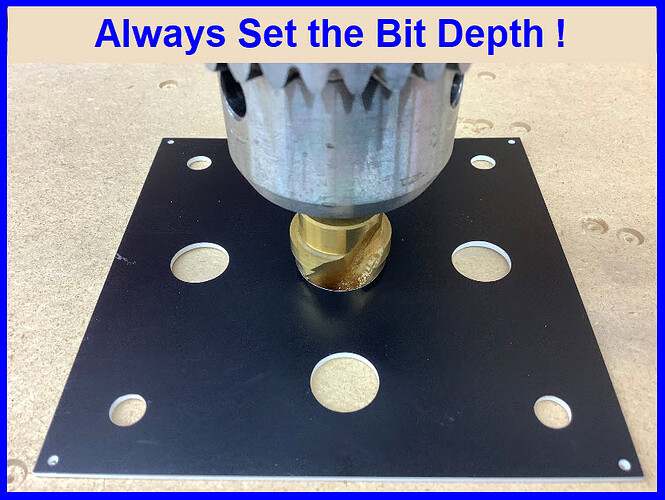

Always clamp your sacrificial backer board to the drill press table and lock in place.

Set ‘Step bit depths’ by drilling into the sacrificial backer board.

Finish drilling each hole with the ‘Step Bit’.

It is best to drill all holes one size then place tape over holes when the finished diameters have been made.

Double fluted spiral step bits:

No center punching !