LarryD

April 12, 2020, 10:24pm

761

Make a wire bending jig for your solderless breadboards.

Now you really don’t need to to cut the PCB at 45°, But doing so gives you two jigs from one board ;).

Make things easy to remember:

5 Likes

LarryD

April 25, 2020, 11:50pm

762

Okay, this is not an electronic or tool tip, but it is a ‘Software Tool Tip’.

Hint

If you place these variables between braces, { }, you can then code fold this area at the opening { bace + and - button.

Hint:

2 Likes

The most usefull forum thread i have ever read, at all time!

Thanks. Specially to larryd

Sexy looking COVID-19 mask @larryd .

Tom...

LarryD

June 17, 2020, 6:56pm

765

Referring back to Post #250 and subsequent Post #758 .

The below addition for the 'Pinch Vise' makes it much more user friendly.

Here we are adding a rubber spacer to keep the jaws open while not compressed.

3/18" O.D. 'Surgical Rubber Tubing' is cut to a height of 1/8" (spacer).

The 1/8" rubber spacer is placed over the 6-32 set screw, i.e. between the two washers, see images below.

When the finger nut (top nylon standoff) is loosened, the 1/8" rubber spacer opens our vise.

This pinch vise can still accommodate a PCB thickness down to a 4 thou object.

LarryD

June 20, 2020, 1:30am

766

For more leverage when tightening the ‘Pinch Vise’, add a 10mm standoff to the offset screw.

Moving the 'screw washer' to the top position helps identify the 'pinch point' 180 degrees away.

Or just use a 10mm long screw

1 Like

LarryD

June 28, 2020, 4:15pm

767

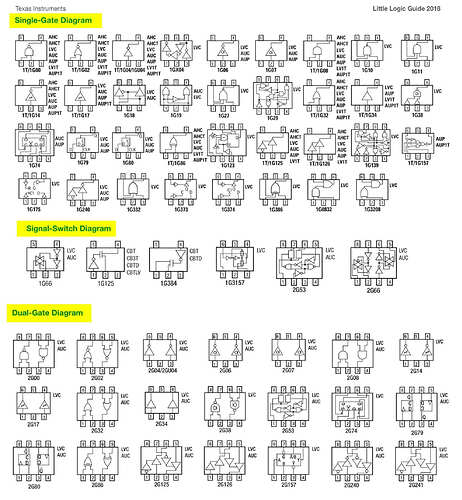

Sometimes all you need is ONE or TWO 'Simple Logic Gate(s)' to finish a design.

See attached PDF:Simple Gates.pdf (508 KB)

Example

1 Like

Where were you when I needed one lousy NOT gate to finish my project last year? I got a 7400 IC (2 inputs tied to make it a NOT) and 3 wasted gates on that IC.

LarryD

July 1, 2020, 9:17pm

770

Program 'Flow Charts' are not used much these days, however, every now and then we might need to make one.

See the attached PDF which discusses how you can use 'MS Word 365' to make your flow charting easier.

FlowCharts Using MS Word.pdf (358.8 KB)

1 Like

LarryD

July 2, 2020, 10:26pm

771

Use an inexpensive RJ45 tool to make cutting Male and Female headers easy.

An inexpensive tool is best because they are easily modifiable.

We must modify the tool by turning the wire cutting blade from a flush cutting blade to a chisel cutting blade.

Remove both the cutting blade and one of the stripping blades.

Put these two blades back to back as in the images and reinstall into the cutting blade position.

The cutting blade is parallel to the tool’s surface, so header cutting results in a nice, unfractured, cut.

1 Like

LarryD

July 5, 2020, 11:08pm

772

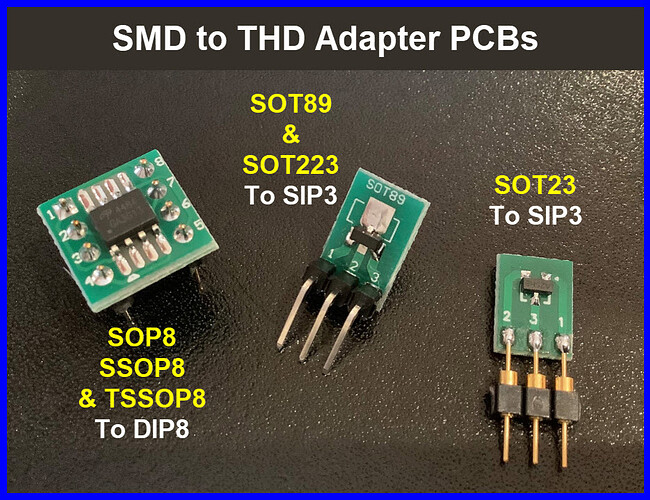

Just so it is documented here:

Use SMD adapter PCBs to convert SMD MOSFETs to THD, example SOT23 to SIP3.

Many of these PCBs are double sided and can accommodate two different package styles.

1 Like

LarryD

July 12, 2020, 11:46pm

773

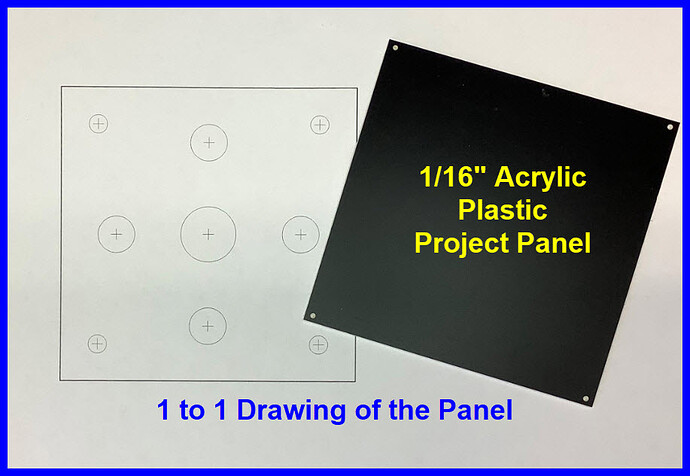

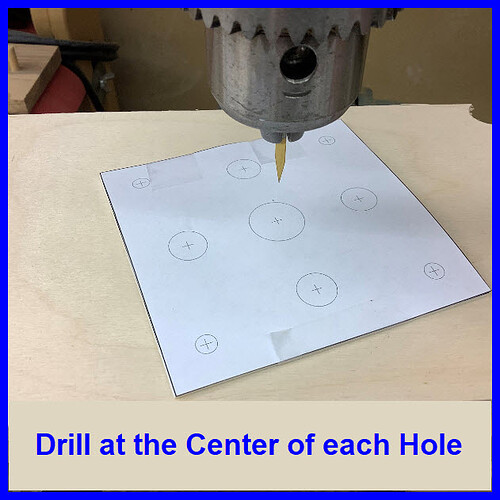

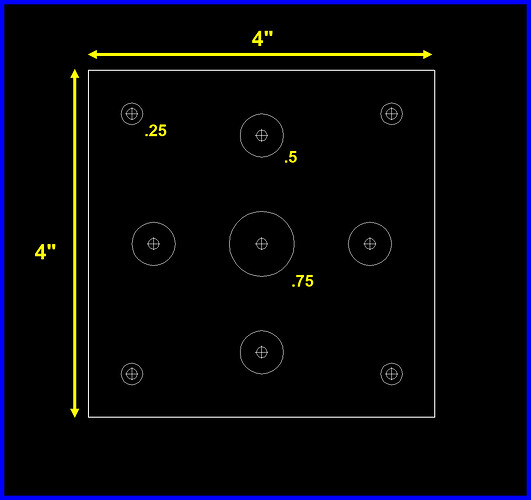

If you do not have access to a CNC machine, you can manually drill accurate ‘Project Panels’ by following this discussion.

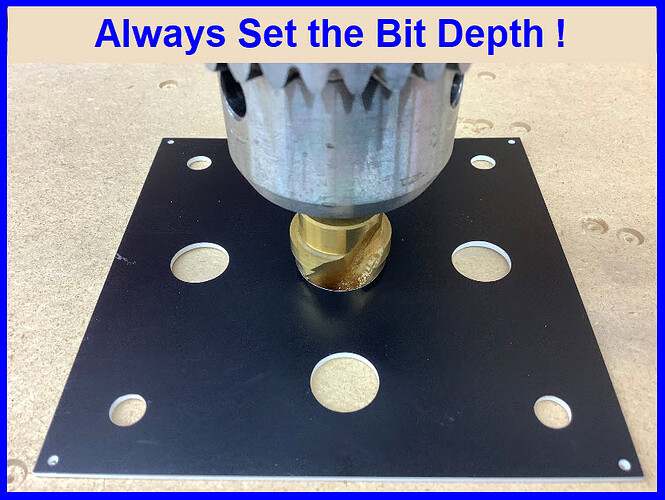

Plastic panels are best drilled manually using ‘Step Bits’ as they do not auger into the panel as regular bits do.

Using your favourite template drawing software, make a 1:1 layout of your panel.

Print the template on ‘Sticky Backed’ label paper. (Regular paper may be used and attached with tape.)

Attach the template to the plastic panel.

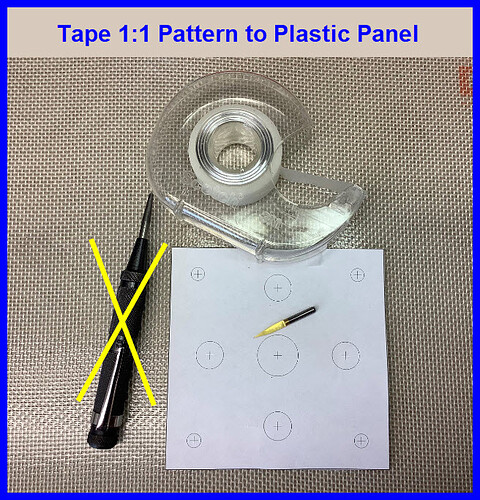

You can avoid center punching holes by using a ‘D’ (engraving) bit to mark hole centers.

Use the pinpoint ‘D’ bit to make a 1/8” hole at the center of each template hole.

These engraving bits are made of Carbide so be careful as they break easily; these are very sharp!

Tune hole centers with a file before progressing further.

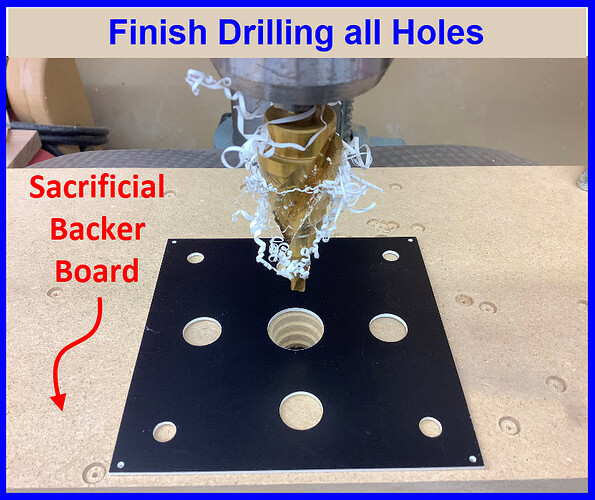

Always clamp your sacrificial backer board to the drill press table and lock in place.

Set ‘Step bit depths’ by drilling into the sacrificial backer board.

Finish drilling each hole with the ‘Step Bit’.

It is best to drill all holes one size then place tape over holes when the finished diameters have been made.

Double fluted spiral step bits:

No center punching !

Plastic panels are best drilled manually using 'Step Bits' as they do not auger into the panel as regular bits do.

Back when I worked in the Sign business an old timer showed me how to get a regular drill bit to work for drilling plastics.

Running the bit into concrete for just a few seconds will dull it enough to keep it from augering in and splitting the plastic. Crazy but it works better than you might think, especially for smaller bits

Keep up the good work this is still my favorite thread!

LarryD

July 16, 2020, 3:32am

775

Attached is a MS Word document that produces labels for 0.1” DuPont header housings.

It is always best to place several of the same header labels on a page as you might accidentally damage one

More Rows and Columns can be added as needed.

Make lettering changes as needed.

Print the page with several labels on it. Colored paper can add interest.

Roughly cut out the label leaving boarder margins.

Place thin ‘Double Stick’ tape on the back of the cut-out. One-inch tape should be easily sourced.

Laminate the front of the label with clear packing tape.

Trim the border of the label with a utility knife.

Remove the tape backing and install the label on the header housing.

Use flush cut nippy cutters to trim any overhanging label.

Attached is a ZIPPED file of the .DOCX file with a sample header label you can modify.

MD5 is C4261B275B923733A5C87E03B60574CF

Header Labels.zip (11.6 KB)

See this link for UNO labels:https://forum.arduino.cc/t/arduino-uno-header-labels/917713?u=larryd

LarryD

July 19, 2020, 4:46am

776

Further to posts #748 and #750

‘Desoldering Spatulas’

Stiffen the aluminum desoldering tool for better handling.

Also, use 600 sandpaper on the aluminum edges to reduce the chances of cutting yourself.

In this version, a bent spine goes all the way to the end of the tool giving best support ;D.

LarryD

July 20, 2020, 12:34am

777

No electronics lab is complete without having a can of ‘Compressed Air’.

We buy 12 cans (12oz) of ‘DUST Off’ at COSTCO for ~ $60.00 CDN ($50.00 USD).

Suggested uses:

Cooling components after soldering.

Cooling Heat Shrink.

Cooling hot glue.

Evaporating IPA when cleaning up after soldering.

Blowing dust from electronic equipment, potentiometers, and other mechanical/moving components.

Cleaning fans.

Cooling a component while trouble shooting PCB problems looking for thermal problems.

Blowing out small parts bin debris.

Cleaning hard-to-get-at places including: hoses, bottles, syringes, screw holes, cracks before gluing.

Cleaning cuttings from Foredom/Dremel tool work.

Cleaning keypads and keyboards.

Blowing out bearings.

etc.

‘ALWAYS’ follow the directions on the ‘Dust Off’ can.

When blowing filings and drilling debris, always wear a dusk mask and eye protection.

'Dust Off' YouTube video:

LarryD

July 27, 2020, 10:23pm

778

Inexpensive tweezers are not much use; however, they can be turned into an especially useful tool.

Follow the discussion in the images below to see how you can make a pair of ‘Screw Tweezers’.

You can also use strips of FR4 material to make tweezer arms then proceed with the conversion process

Make a pair for each screw size that you use: M2, M3, 2-56, 4-40, 6-32, 8-32 etc.

MK1888

July 29, 2020, 12:23pm

779

Good perfboard technique:

Good perfboard technique:

https://www.youtube.com/watch?v=_ypW45Y8VSs

Is it just me, or are his joints not really wetting?

Anyways, here is my little technique for keeping my tools atleast somewhat organised. I just hang them on thumb tacks. For things like my hot glue sticks, I have a clip that goes on the thumb tack, and the clip clips onto a bag or a box.