Soldering to stainless steel

Someone asked how to solder stainless steel (SS) bicycle spokes with Lead solder.

This is a two-step process.

-

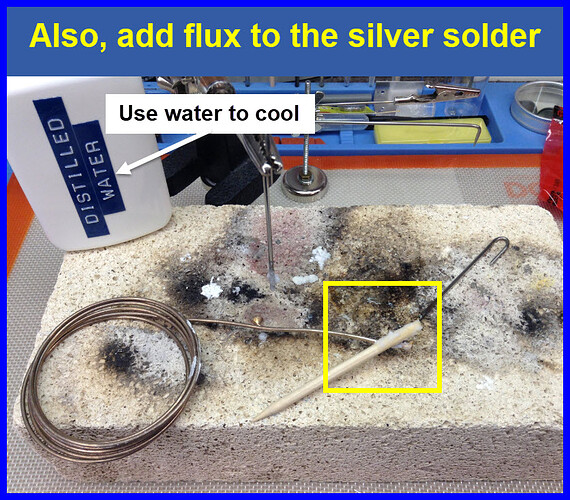

Frist add a small amount of silver solder to the end of the SS spoke. You must use a blowtorch to melt silver solder. It is important you use silver solder flux on surfaces. Silver solder is made from 65% fine silver, 20% copper and 15% zinc.

-

Clean off all remaining flux glass, use a 340°C soldering iron with 63/37 to connect the spoke to your work.

When silver soldering, the tip of the torch blue inner flame must touch the work piece. After a short time, the flux will turn transparent/glassy. Now touch the work with the silver solder wire, depositing a small amount of solder on the work. The solder should flow nicely around the work surface.

Once we get a thin layer of silver solder on an area of the stainless steel, we can easily use normal lead solder to connect this area to solderable components.