Hi Robert-

yes, that 'is' the one I have..

although for myself.. I recommend a different kit.. as the 'tools' were only 'meh' to me.. (can use toothpick, exacto..whatever)

so I opted for the kit of the same price on amazon.com came with 2 mats and two blades..1 stock multi-tool..etc

Im not sure what you mean by, am I cutting the mylar directly with it? the Silhouette Cameo does the cutting.. (but no I am not using the stock 'software' if thats what your asking?)

matter of fact.. there are 'two' approaches I have seen/tested..

but to qualify things first..

the Cameo comes with stock software called Silhouette Studio.. you can buy a better version (30-50 bucks depending on coupons/sales around) called Designer Studio..

which allows .svg support (which is nice I guess).. and a few other things I think?..

but you can import images .jpg, .png, .dxf files..etc.. and trace the image(s) you want to cut out.. takes a bit of getting used to.. and tweaking the settings for best cutting results..

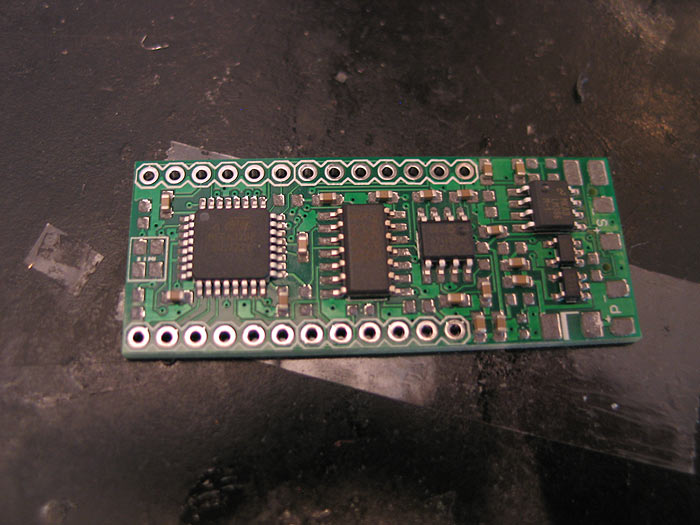

that being said.. I'll outline the two approaches I have tried/tested.. (all of this info is already out there, not new here, just my results, same stuff you seen on hackaday..etc, same cutter too)

method 1:

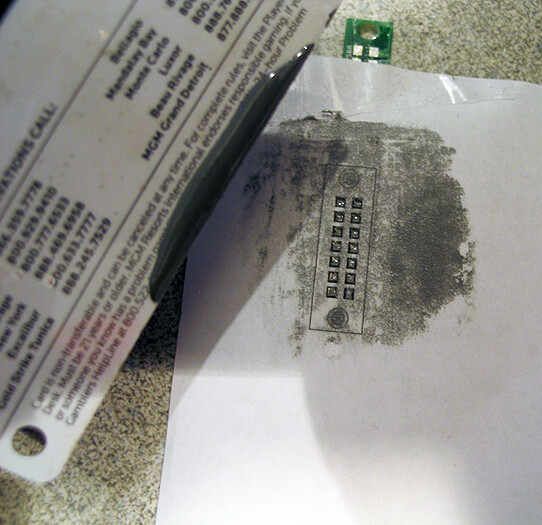

this involves using a custom Eagle script to export your cream layer to a .dxf file (using all straight lines for the pad outlines..thats was the 'key/trick')..

you then -do- use the Silhouette studio to import this .dxf file and cut away..

simple.. HOWEVER.. not the best results.. some slanted pads, not always straight.. depending on the footprints used in the file though, most stencils were still usable (solder paste is somewhat forgiving)

this way is fast and exports directly from Eagle.. easy to use/do..

summary: for anyone of the people 'here' reading this.. they should be able to handle method 2 no problem (especially if "I" did it!) ;).... and there -are- better results to be had..

method 2:

this takes the installation of several other programs/applications..

its more or less a Phython script that that takes your gerbfile file and converts it using a .py script into coords to send to the Cameo.... it more or less re-home/re-aligns the blade after each cut to make them all correct alignment/precise.. takes a long time to make one stencil (originally...read more)

if you are Windows its a bit more...Linux/Mac I guess it much easier by default.. (not sure.. Im a windows sap still!) lol..

anyways.. you'll need to download and install the following:

this is the 'magic script' right here:

download gerber2graphtec from:

matter of fact you can follow my failures and success here on Dangerous Prototypes forum:

it will outline everything way better than i can again.. lol..

once you get everything installed..

there were some NEW updates you'll want to use:

1.) the author made a GUI that makes things MUCH easier..

2.) another member created an 'optimized' .py file to replace the OG one in the gerbertographtec directory...

it makes the stencils cut WAY faster.. minutes rather than hours (which is how long some stencils would take with original script)

just read through it to the end so you can see all the changes and results posted!

tip:

clean you blade before you do a new stencil!!!!

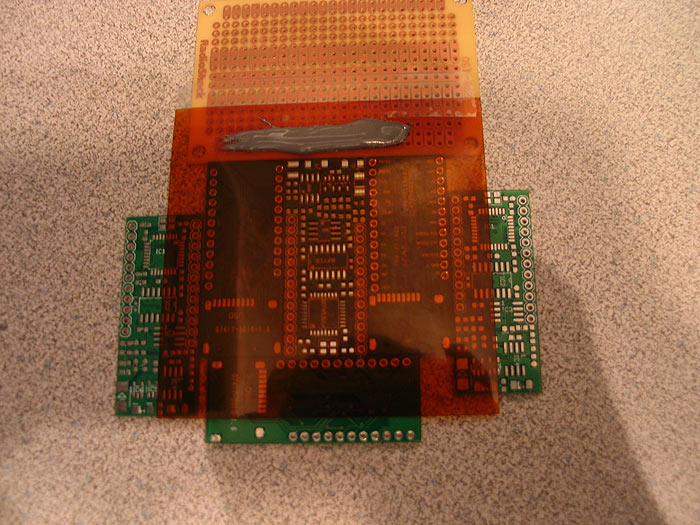

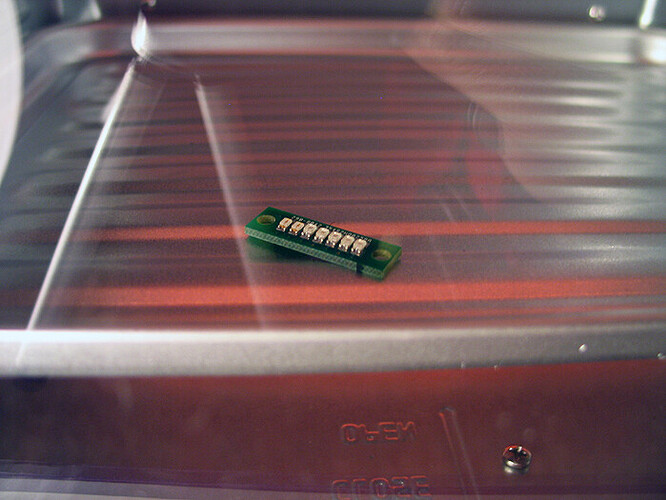

material used matters! (I have used same mylar as Pololu and overhead transparencies!)

making sure the mat is CLEAN (scrape with credit card/library card..etc)

squeegee your mylar/transparency over the sticky mat!!! make sure the cut area is adhered to mat good! (you do NOT want the material to LIFT on a cut with very tight footprint!)

not only is great to do vinyl stickers

masks for glass etching/painting/art

gifts..etc

its a GREAT addition to my in-house work shop!

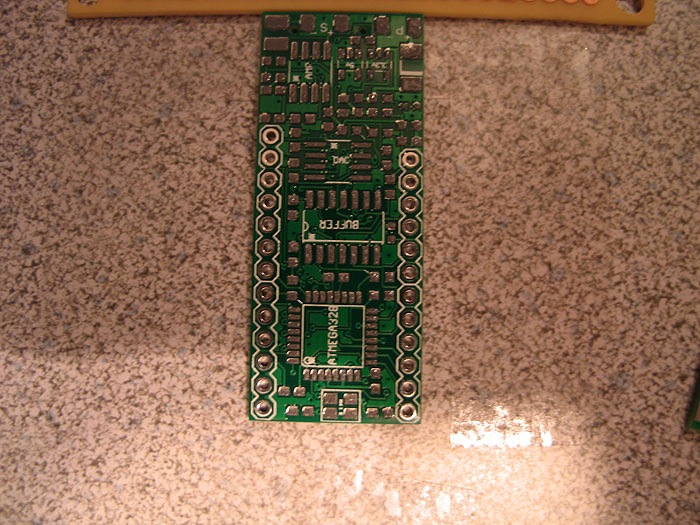

I have already saved myself in $90-$120 in stencils already!.. and cut a few for my buddies project/pcbs!

here was a vinyl sticker I made as a test..

grabbed some image on-line.. traced it in the software.. cut it out:

let me know you have any question Robert... be glad to help!..