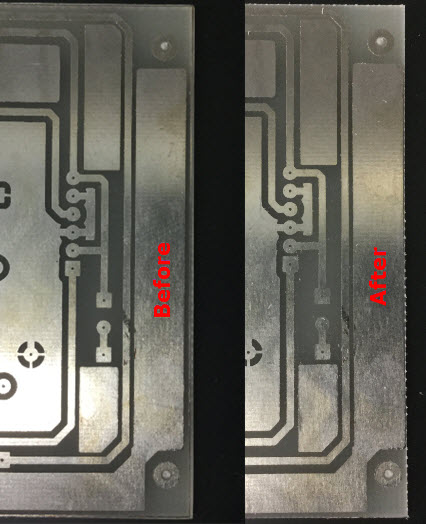

Here is an idea showing how to make professional trimming jobs.

You can remove fractions of an inch from: PCBs, Front Panels etc.

Also square things off.

Not everybody has a setup like that.

I do have a CNC machine, but I still keep a sanding block handy for those jobs.

I glue a full sheet of medium-course sandpaper onto a piece of slightly bigger MDF, with PVA.

Leave it flat on the bench, and slide edge of the the circuit board over it.

Leo..

Yes that works good also.

I made the jig using toggle clamps and floor hardboard.

How long do your bits stay sharp?

I use carbide bits in my router.

I am on my second flush cut bit (in three years).

I use this jig for: PCB glass board, acrylic plastic and wood projects.

Oh, so it's not a big issue. I thought you might be going through them like there was no tomorrow, but that sounds reasonable.

Obviously, the more you use it you may have to replace more.

I trim things quite often.

Also, cut my digits now and then when changing/adjusting the bit.

Note to self, wear gloves.

.

I used a metal file on a small PCB that only needed to be reduced by 1-2mm.

For a larger cut would a hacksaw work?

Files work.

For a larger cut would a hacksaw work?

I have used them.

You can can use a scroll saw with a metal blade.

An oscillating sander works well, you can even add a fence.

The problem with sand paper, files and saws is corners are usually rounded.

This is not to much of a problem for a PCB but more so for face plates and wood projects.

A router and a flush cut bit with the toggle jig allows you to cut/trim fractions of an inch up to about 1/4".