Sorry for my bad english and my basic questions about electronics and programing but I hope you will understand me.

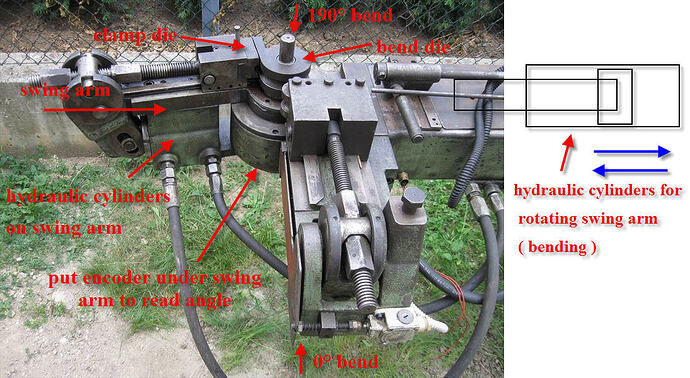

I have hydraulic tube bending machine that I need to controlled with Arduino.

Parts that machine have to be controlled:

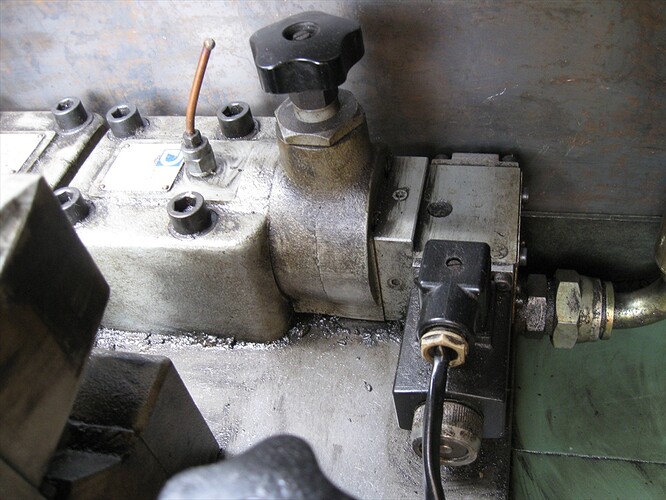

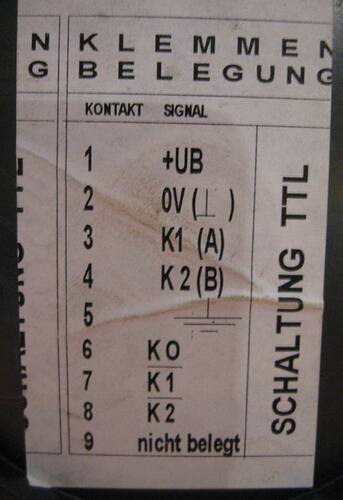

-two 110V AC hydraulic solenoid valvs for two hydraulic cylinders - I have documentation for solenoid valvs

- one hydraulic cylinder for clamping/unclamping die

- one hydraulic cylinder for rotating swing arm ( bending )

How much I search about Arduino what I need.

-Arduino uno

-Relay board for on/off hydraulic solenoid valvs

-encoder for reading angles ( what resolution I need ) to put under swing arm to read angles

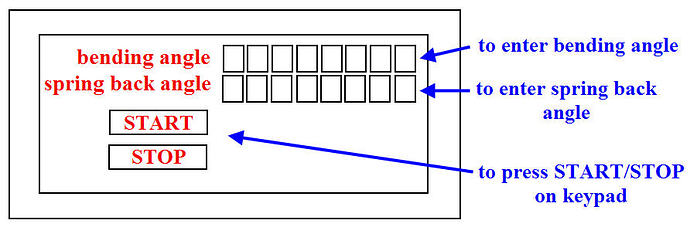

-LCD display + keypad

First to make program how machine will work ( behavior ) - hydraulic cylinder clamp die on swing arm press bend die and rotat to given angle and afrter bending to given angle that hydraulic cylinder on swing arm unclamp and swing arm to return to 0° angle.

-machine can bend from 0-190°.

-swing arm is NOT moving fast

I want machine to work like this:

- set bending angle on keypad

- pres start button on keypad to start bending

- bending to given angle swing arm to return to 0° angle.

Is this possible.

Is someone willing to help me step by step with connecting electronics and programing.

Is someone have solution how to controll this machine.

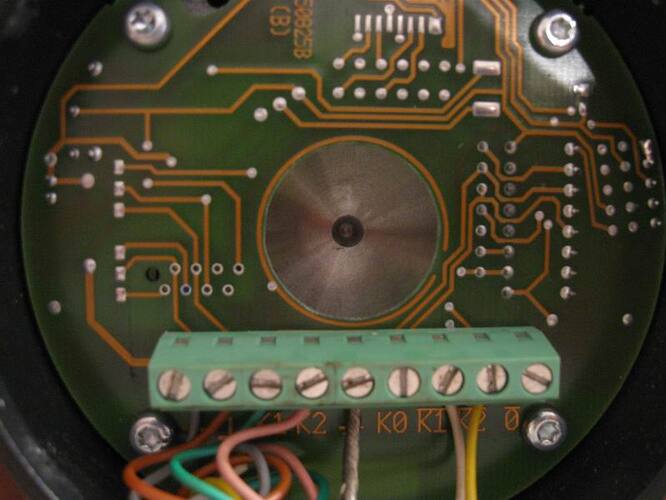

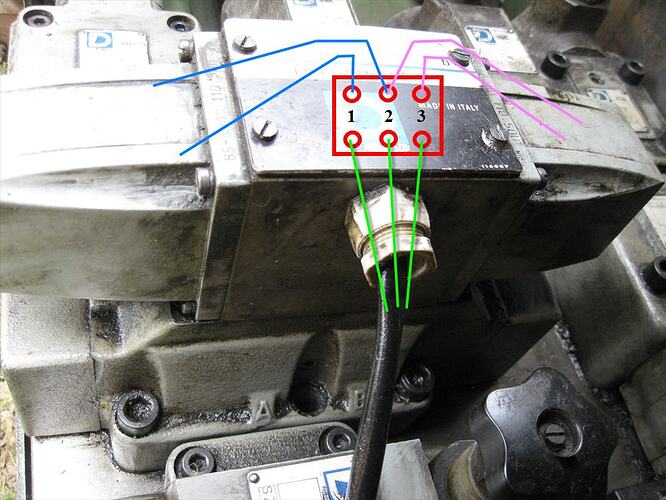

Pictures of machine and hydraulic solenoid valvs.