Try switching to FastAccelStepper, as its superior for ESP32 anyhow.

"This stepper driver uses mcpwm modules of the esp32: for the first three stepper motors mcpwm0, and mcpwm1 for the steppers four to six. "

As it knows how to use ESP32:s mcpwm modules and this makes it much lighter to run.

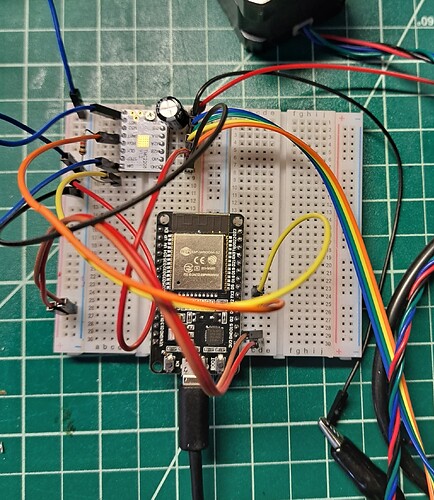

Here is my current test code using FastAccelStepper on a single motor, it has some extras but you can probably get what you need out of it. It reports actual mm/s speeds, currently its set to 4mm per revolution. So just change it in the serial reports and you get actual speeds.

Ok, now i realized that you were allready using FastAccelStepper

I think your issues is probably about how and where you instruct the stepper to move. Are you using RTOS? If not, start using RTOS. In this example i also use RTOS to run the motor on a different core on its own loop, and serial reporting on another core on its own loop.

But this is just a really simple, move back & forth and set speeds & accelerations test code for my test jig.

/*

ESP32 ONLY! RUNS ON TWO CORES.

DOES NOT USE EN PIN, DIRECTLY SOLDERED TO GROUND TO KEEP IT SIMPLE.

SET SPEED, ACCELERATION & CURRENT IN SERIAL TERMINAL LIKE THIS

TO SET SPEED:

-------------

TO SET 1000, INPUT 1000

TO SET 2000, INPUT 2000

MAX 99999, INPUT 99999

ACCELERATION:

-------------

TO SET 1000, INPUT 101000

TO SET 2000, INPUT 102000

MAX 99999, INPUT 199999

CURRENT:

--------

TO SET 100mA, INPUT 200100

TO SET 1000mA, INPUT 201000;

MAX 2000mA, INPUT 202000;

*/

//LIBRARIES THAT YOU NEED

#include <TMCStepper.h> // https://www.arduino.cc/reference/en/libraries/tmcstepper/

#include "FastAccelStepper.h" // https://www.arduino.cc/reference/en/libraries/fastaccelstepper/

//DEFINE YOUR STARTING VALUES!

int AMPS = 2000; // SET STARTING CURRENT MAX 2000

int micro = 0; // SET MICROSTEPS

int Maccell = 1000; // SET STARTING ACCELERATION

int Mspeed = 1000; // SET STARTING STEPS/S

int MMperRev = 2; // SET MM PER REVOLUTION

int moveMM = 57; // SET MOVEMENT IN MM

float StepsPerRoation = 200; // PHYSICAL STEPS OF MOTOR, NO MICROSTEPS INCLUDED

//SET THESE 3 PER YOUR CONNECTIONS, AND YOU ARE GOOD TO GO!:

#define DIR_PIN 4 // Direction

#define STEP_PIN 0 // Step

#define SERIAL_PORT Serial2 // HardwareSerial port

#define STALL_VALUE 255 // [0..255]

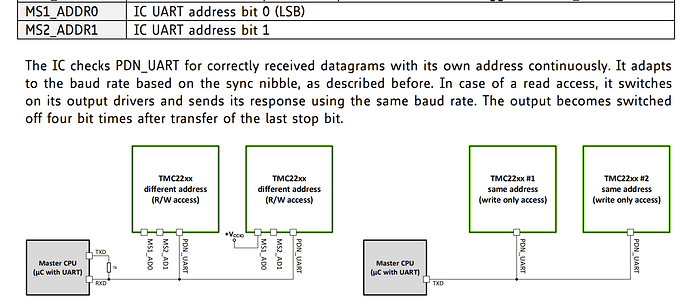

#define DRIVER_ADDRESS 0b00 // TMC2209 Driver address according to MS1 and MS2

#define R_SENSE 0.11f // 0.11 for MKS TMC2209

TMC2209Stepper driver(&SERIAL_PORT, R_SENSE, DRIVER_ADDRESS);

using namespace TMC2209_n;

FastAccelStepperEngine engine = FastAccelStepperEngine();

FastAccelStepper *stepper = NULL;

unsigned long howLong=0;

TaskHandle_t Motor;

TaskHandle_t Print;

TaskHandle_t Input;

void setup() {

// INTITIALIZE SERIAL0 ITERFACE

Serial.begin(115200);

Serial.println(F("---------------------------------------------------"));

Serial.println(F("UART0 serial output interface intitialized @ 115200"));

// INITIALIZE SERIAL2 UART FOR TMC2209

SERIAL_PORT.begin(115200); //,SERIAL_8N1, 16, 17

Serial.println(F("UART2 interface for TMC2209 intitialized @ 115200"));

Serial.println(F("---------------------------------------------------"));

//TMCSTEPPER SETTINGS

driver.begin();

driver.toff(2); // [1..15] enable driver in software

driver.blank_time(24); // [16, 24, 36, 54]

driver.hysteresis_start(1); // [1..8]

driver.hysteresis_end(12); // [-3..12]

driver.rms_current(AMPS, 0.01); // motor RMS current "rms_current will by default set ihold to 50% of irun but you can set your own ratio with additional second argument; rms_current(1000, 0.3)."

driver.seimin(1); // minimum current for smart current control 0: 1/2 of IRUN 1: 1/4 of IRUN

driver.semin(15); // [0... 15] If the StallGuard4 result falls below SEMIN*32, the motor current becomes increased to reduce motor load angle.

driver.semax(15); // [0... 15] If the StallGuard4 result is equal to or above (SEMIN+SEMAX+1)*32, the motor current becomes decreased to save energy.

driver.sedn(4); // current down step speed 0-11%

driver.seup(2); // Current increment steps per measured StallGuard2 value 5 seup0 %00 … %11: 1, 2, 4, 8

driver.iholddelay(3); // 0 - 15 smooth current drop

driver.TPWMTHRS(0); // 0: Disabled, 0xFFFFF = 1048575 MAX TSTEP.

// StealthChop PWM mode is enabled, if configured. When the velocity exceeds

// the limit set by TPWMTHRS, the driver switches to SpreadCycle.

driver.TCOOLTHRS(0); // 0-7 TSTEP

// 0: TPWM_THRS= 0

// 1: TPWM_THRS= 200

// 2: TPWM_THRS= 300

// 3: TPWM_THRS= 400

// 4: TPWM_THRS= 500

// 5: TPWM_THRS= 800

// 6: TPWM_THRS= 1200

// 7: TPWM_THRS= 4000

driver.pwm_autoscale(true); // Needed for stealthChop

driver.en_spreadCycle(false); // false = StealthChop / true = SpreadCycle

driver.microsteps(micro); // microsteps

driver.shaft(false); // direction

driver.intpol(true); // interpolate to 256 microsteps

//driver.ihold(2); // hold current 0=1/32 … 31=32/32

//driver.irun(31);

driver.SGTHRS(STALL_VALUE);

//driver.I_scale_analog(0); // if 5v vdd

//ACCELL STEPPER SPEED & ACCELERATION

engine.init();

stepper = engine.stepperConnectToPin(STEP_PIN);

stepper->setDirectionPin(DIR_PIN);

stepper->setSpeedInHz(Mspeed); // STEPS PER SECOND

stepper->setAcceleration(Maccell);

if (micro!=0) {StepsPerRoation=StepsPerRoation*micro;};

xTaskCreatePinnedToCore(PrintTask, "Print", 2000,NULL,tskIDLE_PRIORITY,&Print,1);

xTaskCreatePinnedToCore(MotorTask, "Motor", 5000,NULL,5,&Motor,0);

xTaskCreatePinnedToCore(InputTask, "Input", 5000,NULL,2,&Input,1);

}

void loop() {

vTaskDelete(NULL);

}

//PRINT SERIAL--------------------------------------------------

void PrintTask(void*) {

int SSpeed;

int steppes;

float ActualSpeed;

float MaxSpeed;

for(;;) {

steppes = driver.TSTEP();

SSpeed = 12000000./(steppes*256.);

ActualSpeed = (SSpeed/StepsPerRoation)*MMperRev;

if (ActualSpeed > MaxSpeed) {MaxSpeed = ActualSpeed;};

if (ActualSpeed == 0) {MaxSpeed = 0;};

Serial.print("ACTUAL");Serial.print(F(" / "));Serial.print("MAX");Serial.print(F(" / "));Serial.print("AVARAGE");Serial.print(F(" / "));Serial.println("REQUESTED");

Serial.print(ActualSpeed,2);Serial.print(F(" / "));Serial.print(MaxSpeed,2);Serial.print(F(" / "));Serial.print((moveMM/(howLong/1000.)),2);Serial.print(F(" / "));Serial.print((Mspeed/StepsPerRoation)*MMperRev,2);Serial.println(F(" MM/S"));

Serial.print(SSpeed);Serial.print(" / ");Serial.print(MaxSpeed/(MMperRev/StepsPerRoation),0);Serial.print(" / ");Serial.print((moveMM/(MMperRev/StepsPerRoation))/(howLong/1000.),0);Serial.print(" / "); Serial.print(Mspeed);Serial.println(F(" STEPS/S"));

Serial.print(60.*(SSpeed/StepsPerRoation),0);Serial.print(" / "); Serial.print(60.*((MaxSpeed/(MMperRev/StepsPerRoation))/StepsPerRoation),0);Serial.print(" / "); Serial.print((((moveMM/(MMperRev/StepsPerRoation))/(howLong/1000.))/StepsPerRoation)*60.,0);Serial.print(" / "); Serial.print(60.*(Mspeed/StepsPerRoation),0);Serial.println(F(" RPM"));

Serial.print(Maccell);Serial.println(F(" ACCELERATION"));

Serial.println("----------------------------------");

Serial.print(driver.cs2rms(driver.cs_actual()),DEC);Serial.print(" / ");Serial.print(AMPS);Serial.println(" MA MOTOR CURRENT");

Serial.print(stepper->getCurrentPosition());Serial.print(" / ");Serial.print(stepper->targetPos());Serial.println(" STEP POSITION");

Serial.print(driver.SG_RESULT());Serial.println(" STALLGUARD");

Serial.print(steppes);Serial.println(" TSTEP");

Serial.print(float(howLong/1000.),2);Serial.println("S LAST MOVEMENT DURATION");

Serial.print(driver.microsteps());Serial.println(F(" MICROSTEPS"));

Serial.println("----------------------------------");

vTaskDelay(100);

}

}

//CHECK FOR SERIAL COMMANDS--------------------------------------------------------

void InputTask(void*) {

for(;;)

{

int dataIn=0;

if (Serial.available()) {

dataIn = Serial.parseInt();

if (dataIn>0 && dataIn<10000) {

Mspeed=dataIn;

stepper->setSpeedInHz(Mspeed);

};

if (dataIn>=100000 && dataIn<200000 ) {

Maccell=dataIn-10000;

stepper->setAcceleration(Maccell);

};

if (dataIn>=200000 && dataIn<=202001 ) {

AMPS=dataIn-200000;

driver.rms_current(AMPS, 0.01);

};

};

vTaskDelay(5);

}

}

//MOTOR--------------------------------------------------------

void MotorTask(void*) {

for(;;)

{

unsigned long timeIs = millis();

stepper->moveTo(moveMM/(MMperRev/StepsPerRoation),true); // TRUE makes this a blocking function. Remove it to use it as non blocking.

howLong = millis()-timeIs;

vTaskDelay(2000);

stepper->moveTo(0,true); //

vTaskDelay(2000);

}

}