Hi guys

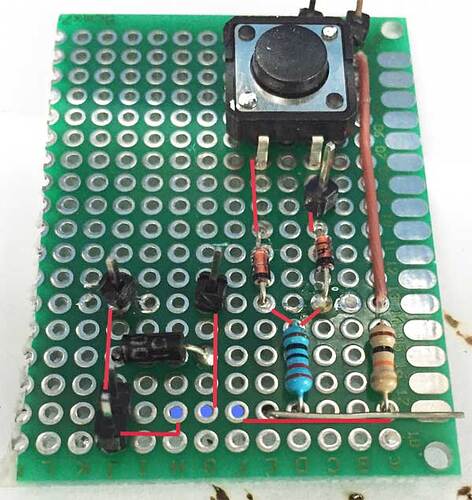

I'm working on a small perf board 5x7cm and I've got the components laid out buy a few connections to make between holes and I was wondering what is good practice.

For example I had a long raceway of about 10 holes so I used a cable, peeled the tips and connected the ends. That way I avoid wasting solder.

But I have other connections to make that only span about 2 or 3 holes. In a past project I used the clipped ends of a resistor, laid it over a 4 hole stretch and added solder at every hole in between but it was a waste of solder. The advantage of it was that I could bend the solid wire into L shapes or X shapes and connect many points of the board.

Is stranded wire the usuales of connecting points on a perf board? What else do you suggest for small 3 to 5 hole connections?