When reflowing PCBs in a DIY reflow oven, I'm encountering issues where solder bridges are forming beneath SMD components, making it difficult to identify the faulty location. What could be causing this problem, and what steps can I take to prevent or address it effectively?

-

DIY ovens need to be hot enough for long enough to get good results.

-

Solder paste that doesn’t have sufficient flux can cause this.

-

Use 63/37 solder paste.

- Suggest you add a little liquid flux to the paste, mix well; Your resulting paste should have a slight watery look to it. See the shine on the solder paste dots.

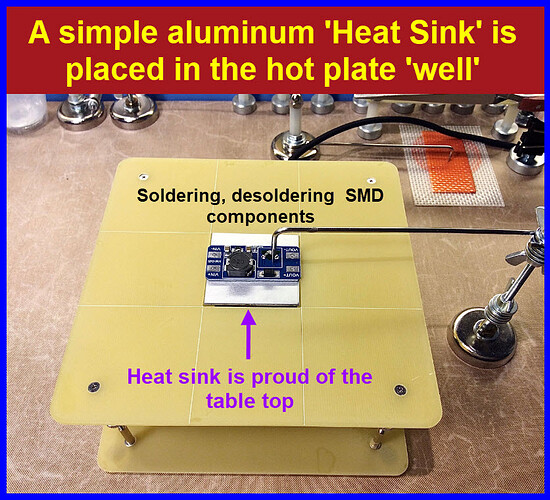

- You may have better luck with using a hot plate with a hold down clamp therefore get better PCB contact with the hot surface. As seen below.

- Large hot plates are available too:

Are you using a stencil? Some of those components look like they have a LOT of solder.

This topic was automatically closed 180 days after the last reply. New replies are no longer allowed.