Hey, I'm an avid Arduino user.

Just going to buy one, and I want my first project to be this, but a really simplified version. I'm going to use a soil Moisture sensor connected to an arduino, which is connected to a relay, which will be connected to a water pump.

So a few questions.

I was told about using a relay by someone with technical experience, I would like to know why is the relay necessary? Why do I need to tell the relay to turn on the motor, why can't I tell the motor to turn on straight away? (eliminating the middle man?)

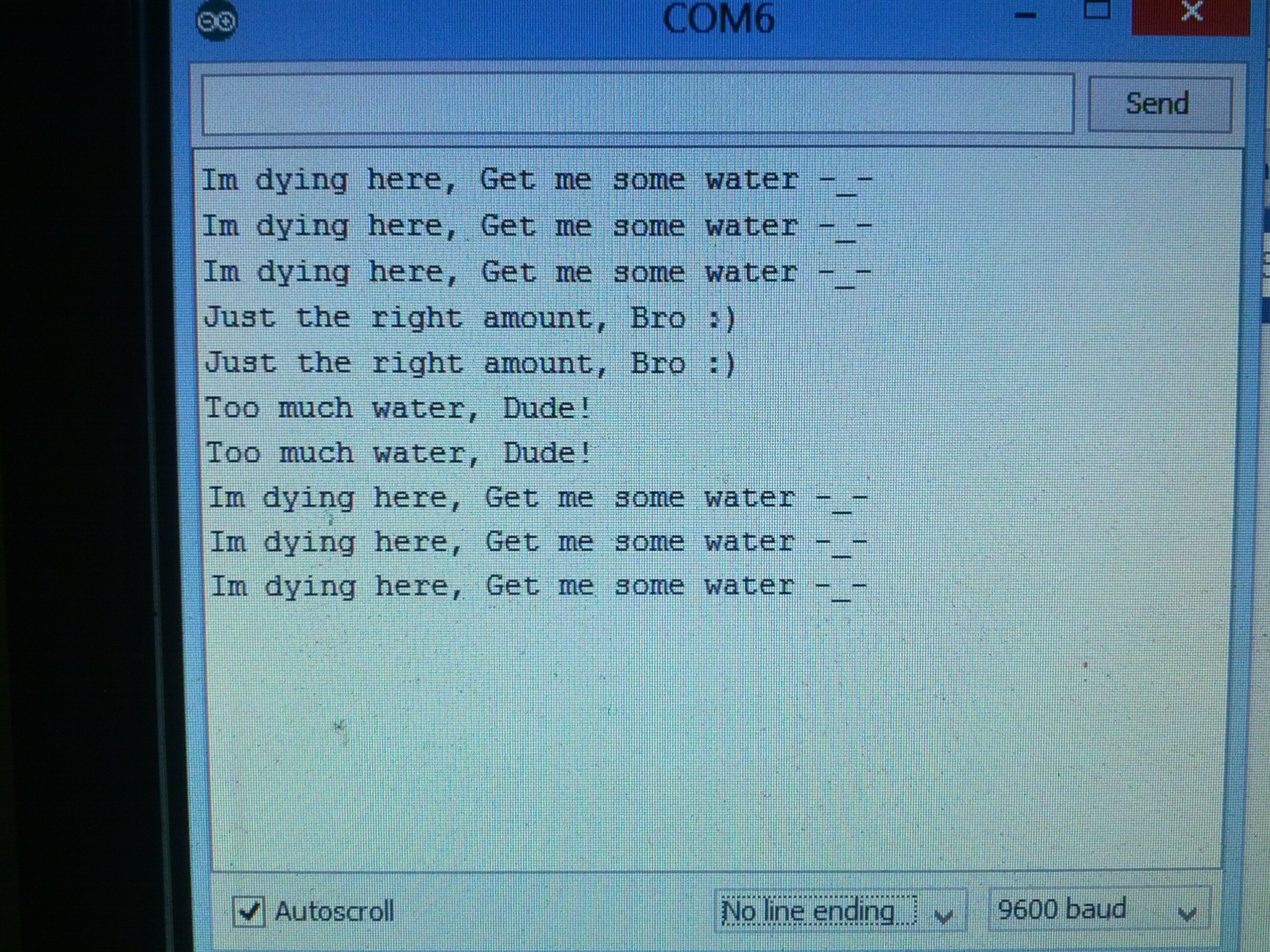

Secondly, I have no major coding experience, so I was hoping someone could help me. Before I purchase the pump, I want to make sure the sensor coupled with the arduino works perfectly, so I want it to show sensor values on a popup window (maybe using the "serial.printIn" Command?)

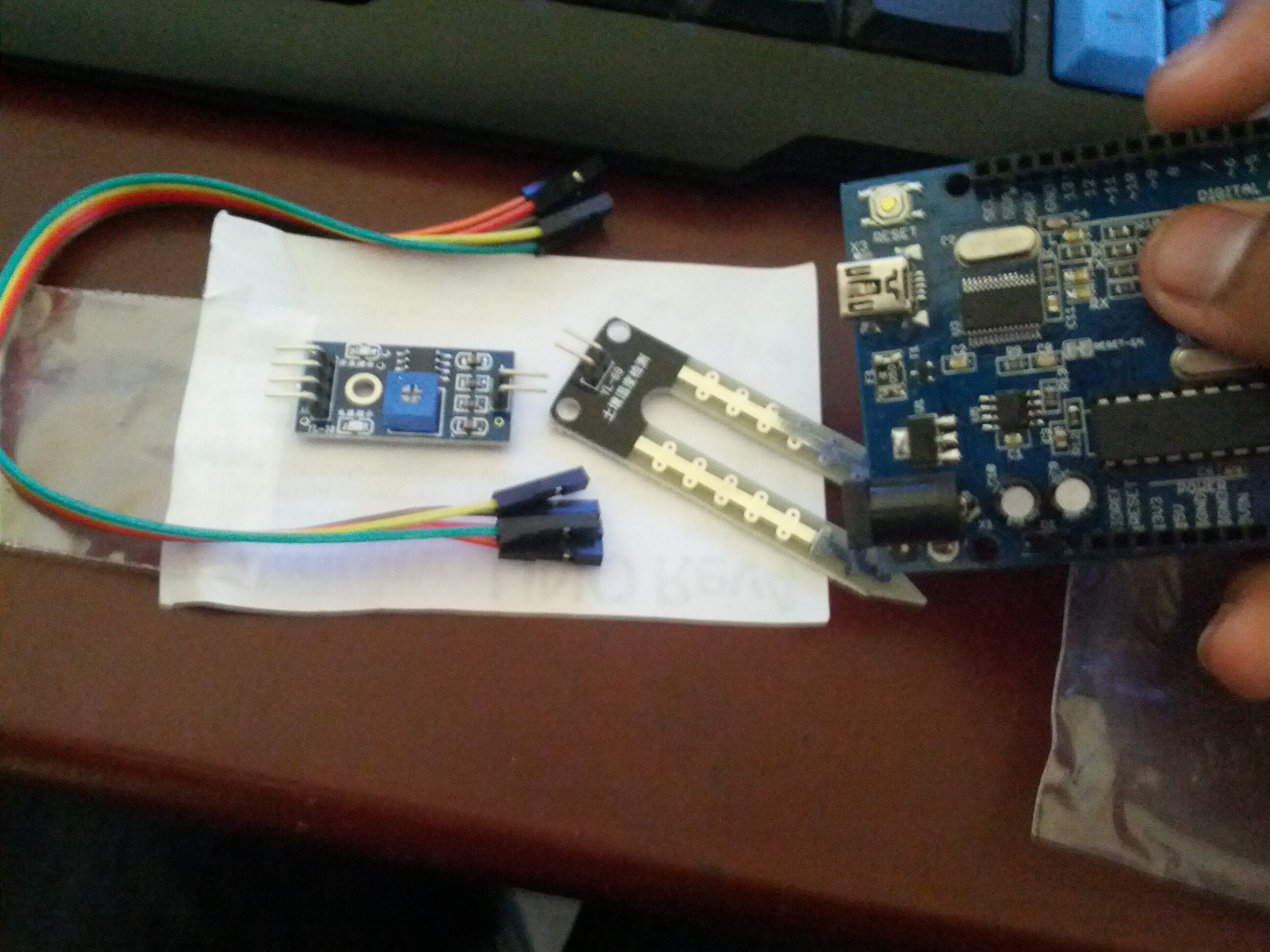

So this is the sensor im going to use

http://www.lankatronics.com/soil-dust-humidity-water-moisture-sensor.html

I checked out some stuff online and I saw some codes but they used a grove shield, however I want to connect this without a Grove shield.

So could I get some kind of basic code that reads the sensor value and outputs it to the computer screen. Just as simple as that for now, I want to code the major part of it using the relay and pump myself (or atleast try to), So just need help on the starting point.

Oh, and a little help on how to connect the sensor to the Arduino, which connections to use and whatnot

Will be purchasing the Arduino Uno and the Sensor tomorrow.

Thanks for the help ![]()