Hello All,

Project: Glow Plug Control System for Diesel Engine

Specifics: Temperature based control to determine control circuit timing of glow plug circuit.

Looking for some basic guidance to get the ball rolling on this project. I already have most of the main components, I have written a high level overview of the complete system and expected operations. I also have got code running for the Bosch 0 280 130 026 NPT Temperature Sensor.

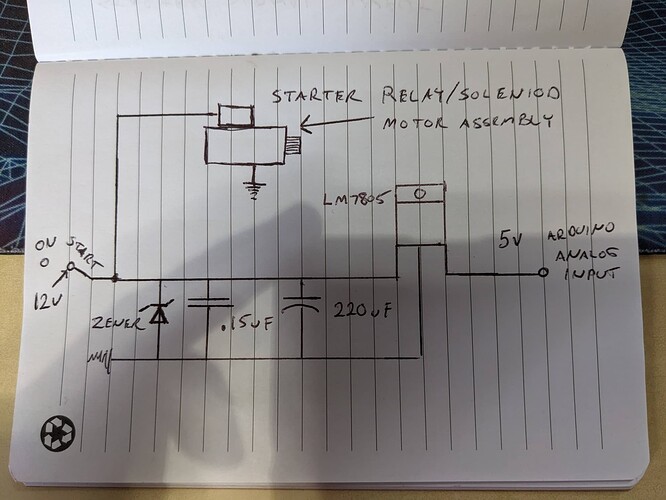

I have several inputs that are from the Automotive 12v system that I believe need to be brought down to 5v logic level input signals.

Input signals:

- 12v KeyOn power, this will provide power to the unit

- 12v Starter signal, this will indicate when in is cranking

- 12v Alternator signal, this will indicate engine is running

3a) VR signal reading from flywheel teeth as already planned to implement with tachometer, Potentially cleaner signal and easier to implement.

Now I know that those 12v signals will need to be conditioned and cleaned to prevent damage to the Arduino. I also know that has been talked about extensively already, but I would like some advice on building a shopping list.

I already have a Traco TSR-1 12v to 5v DC-DC converter I was going to use to send the 5v signal to the Bosch Temp Sensor.

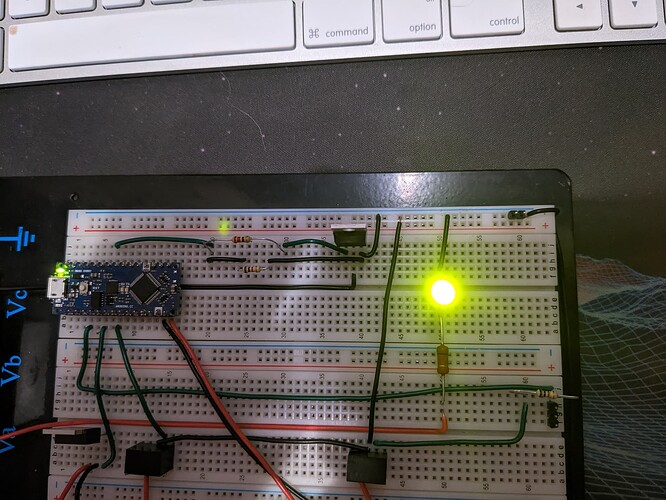

Currently using the Arduino 5v output, 1K resistor and then input that signal on A0 with the second pin going to the Arduino ground. This produces a clean signal that is already been coded and tested and responds to temp changes as expected.

My intention is to use the Arduino 5v output through a N-Channel Mosfet to drive the 12v 75amp relay that will power the 4 glow plugs.

Now on those 12v input signals, I understand I am going to need some 10uF capacitors and a 7805 linear voltage regulator on each input to pull down the 12v to 5v for analog signaling.

In addition for anyone thinking to ask my experience...I have been working in Automotive for 30 years, I have a excellent understanding of electrical, but only a basic to intermediate knowledge of electronics. In regards to the programming aspect I have only general understanding from a couple basic programming course but luckily I have a talented friend who is helping me with the coding side of things, I also have you guys (and gals) ![]()

I am including an a couple attachments for your review so you can get the big picture. Ultimately we are re-creating a factory Glow Plug controller that we do not have and is not readily available as the engine was never sold in the US.

I have all the hardware to implement the actual circuit such as the glow plugs, temp sensor, relay, arduino, multimeter, test battery for 12v power, etc. I also have some zener diodes, 330ohm, 1k ohm and 10k ohm resistors.

The controller_overview is my written work and the 4M40_glowplug ops is pulled from the factory service manual.

My goal of this post is to build a list of electronic items I need to order to be able to successfully complete the project. In addition, any overall guidance on the project. I will search threads for things such as how to implement the 7805, how to wire up the N Channel Mosfet, etc.. as I am sure those topics have been covered before me.

And Yes, I have a copy of the ST AN2689 ![]()

Mitsu_4M40_GlowPlug_Ops.pdf (157.4 KB)

Controller_Overview.pdf (29.8 KB)

T