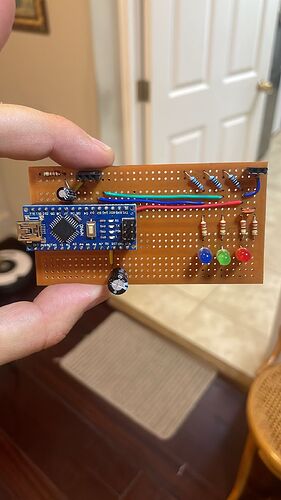

I am working on a control circuit for a humidifer in a shiitake mushroom growing room. That equipment consists of an AC motor that spins a disk spraying mist over the room, rated at 300W working under 220Vac. The arduino opens or closes the circuit via a solid state relay SSR25DA, based on the humdity read by the DHT sensor.

I have designed the four following stages:

Stage 1: Humidity below 75%. SSR is on. Red led on.

Stage 2: Uptrend from 75% to 85%, SSR on. Red led on, green led flashing.

Stage 3: 85% or more reached. Only blue light on. Relay is off.

Stage 4: Downtrend from 85 to 75%. Only green led steady.

Error code: upon NaN read by sensor: flash green.

The circuit failed when using the humidifier as a load, with error code.

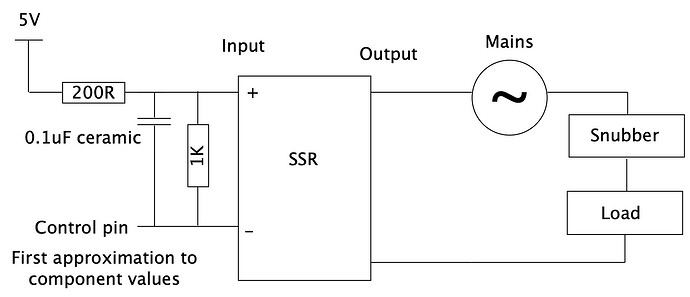

This circuit works fine with loads light a light bulb. I found that turning on the egg beater close to the circuit leads to the same error. This egg beater runs at 300W too. I added a snubber at the 5V terminals of the SSR. With this, i could run the egg beater to speed 4 (out of 5) with no failure. failing at 5. (when connected as load, at a distance of 5m of the arduino). This makes me think that maybe the mains cables themselves cause EMI on the arduino (distance = 0.5m from the SSR to the soldered breadboard. Not sure.

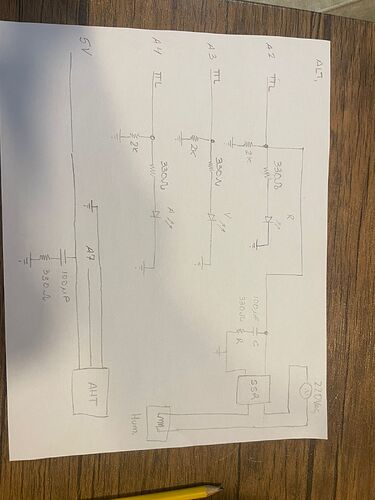

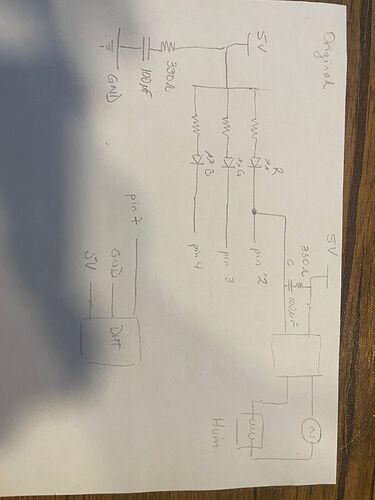

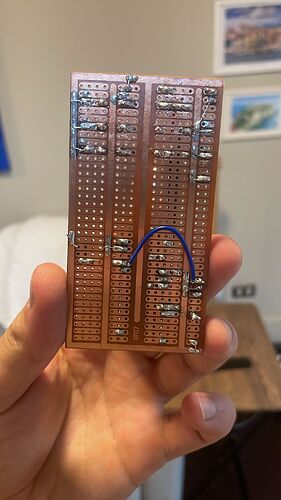

I have provided code and schematic. I am thinking of implementing a second circuit but wanted to ask for suggestions first.

#include <DHT.h> // Temp/hum

#include <Wire.h> // I2C

#define DHTPIN 7 // what pin we're connected to

#define DHTTYPE DHT22 // DHT 22 (AM2302)

DHT dht(DHTPIN, DHTTYPE);

float hum;

float marcador;

float temp;

void setup() {

// put your setup code here, to run once:

Serial.begin(9600); // Inicio comms Serial Monitor

Wire.begin();

dht.begin();

Serial.println("DHT iniciado");

pinMode(2, OUTPUT);

pinMode(3, OUTPUT);

pinMode(4, OUTPUT);

}

void flashinggreen() {

digitalWrite(3, LOW); //

delay(200);

digitalWrite(3, HIGH); //

delay(200);

digitalWrite(3, LOW); //

delay(200);

digitalWrite(3, HIGH); //

delay(200);

digitalWrite(3, LOW); //

}

void loop() {

// put your main code here, to run repeatedly:

String espacio = " ";

hum = dht.readHumidity();

temp = dht.readTemperature();

String nan = "NAN";

Serial.println(hum + espacio + temp);

String Hum = String(hum);

Serial.println(Hum);

if (isnan(hum)){

Serial.println("Error");

digitalWrite(2, HIGH); // apago luz roja

digitalWrite(4, HIGH); // apago azul

flashinggreen();

}

else{

if (hum <= 75) // Baja de humedad

{

digitalWrite(2, LOW); // prendo luz roja

digitalWrite(3, HIGH); // apago luz verde

digitalWrite(4, HIGH); // apago azul

Serial.println("Hum bajo 75, relay on");

delay(5000);

marcador = 1;

}

else{

if (hum<= 85){ // transicion

Serial.print("Verde transicion, marcador = ");

Serial.println(marcador);

if (marcador >= 1) {

digitalWrite(2, LOW); // mantengo luz roja

flashinggreen();

digitalWrite(4, HIGH); // apago azul

Serial.println("Hum normal, relay mantiene");

delay(1000);

}

else{

digitalWrite(2,HIGH); // apago roja

digitalWrite(3, LOW); // luz verde fija

digitalWrite(4, HIGH); // apago azul

Serial.println("relay off, en bajada");

delay(5000);

}

}

else{ // humedad mayor a 85

digitalWrite(2,HIGH);

Serial.println("Sobrehumedad, relay off");

digitalWrite(2, HIGH); // apago luz roja

digitalWrite(3,HIGH); // apago luz verde

digitalWrite(4, LOW); // prendo azul

marcador = 0;

delay(5000);

}

}

}

}

New circ

Original circ