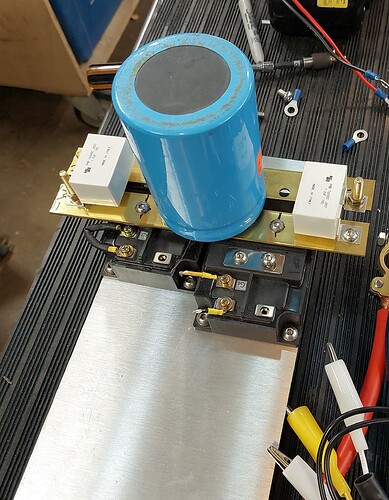

Hello, I am working on converting an old Volvo to full electric, using a repurposed forklift traction motor. I have been following Damien MaGuire's lead on his Youtube channel (where he converted a BMW for 1000 Euro). I have built the power stage using 2 large IGBTs and capacitors, and the assembly does turn power on and off when I manually load and unload the gate on the IGBT.

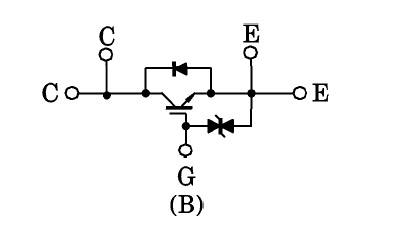

That leaves the portion that supplies the logic to turn the IGBT on and off in pulses. I thought an Arduino might be a good choice since they are used to control small motors, but I realized the motor controller boards are actually shunting the big power -- they are not sending successive pulses of +12v and -12V to turn the gate on and off.

I'd still like to use the Arduino, since the coding looks so simple and elegant, and I'm sure I can come up with something that will work-- once I get the hardware sussed.

So, what sort of chip or controller should I use in conjunction with the Arduino to give the +12v/-12V pulsing needed to cycle the IGBT?

Thank you.