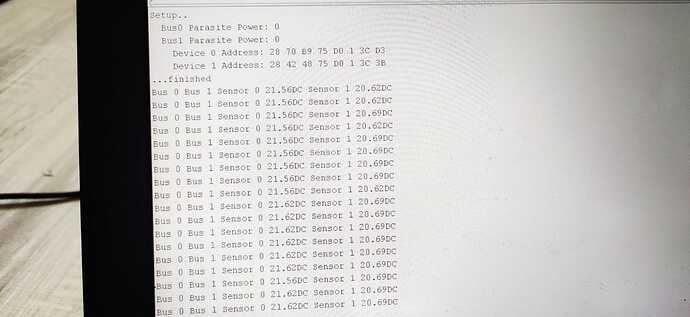

Hi, I have 5 sensors on a OneWire bus, and I decided to replace one of them with a new one because one of the sensors sometimes reported -127C (error). Well, I bought a couple of new sensors, and I decided to replace one my old sensor with a new one, and it didn't work, all sensors started reporting -127C error. ![]()

I tried to find out what is wrong, and I found some kind of incompatibility between my old sensors and the new ones.

Here is what I found out:

If I only connect new sensors they work fine, and if I only connect old sensor they also work fine, but if I connect them together (or replays an old with a new one) I only can see the address of old sensor, but even old sensors start reporting -127C error.

What difference I found between old sensor and new ones:

Here is adreses of old sensors:

**Number of devices: 5 **

**2888f8cf02000021 **

287c832909000013

28e2e0cf0200006f

2896cf2d05000088

28b75b280900009b

And here is the new ones:

Number of devices: 2

2861641195cf3da1

2861641197f1a311

As you can see new addresses don't have 0000 in it, I don't know what those 0000 means, but sensors are incompatible.

Any idea what is going on?

What addresses your sensors have?

By the way, I use esp8266, and libraries: OneWire.h and DallasTemperature.h