I've tried before at cutting out a project box to accommodate a 128x64 oled display, and also a 2004 LCD... It wasn't easy and didn't look perfect either.

The next time, I ordered a custom 3d printed casing for an internet radio that used a 1602 LCD. The fit was perfect, but overall a bit pricey to be doing every time.

So I'm researching ways of mounting these displays...

Thus far, I've found a pattern for a 3d printed bezel that I could order to suit the 1602 display, which may help get a better finish.

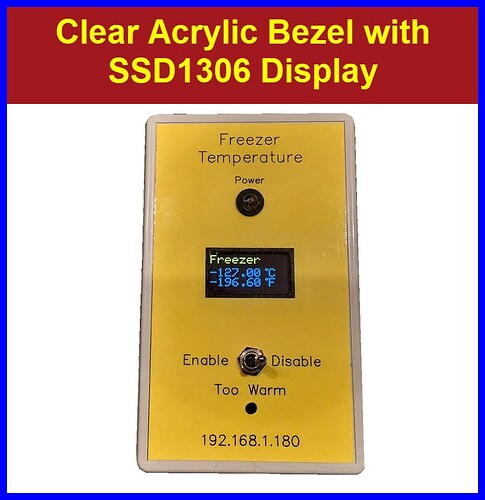

Also a perspex casing on AliExpress to accommodate a 0.96" oled - which is ok if you want the whole thing exposed outside a casing.

Presumably other people have encountered this, so I'd love to know what go-to ideas you have? Thanks

Did you use a laser cutter to cut your wood?

I have found that if you do you can get good results, providing you get it right. I found the trick was to cut back half the thickness of the wood on the top and bottom so the screen fits closer to the aperture. I cut it back using a sharp scalpel or Stanley knife.

P.S. I don't see any recesses on that 3D printed design. You could reasonably design that in.

In the UK there is this site: https://www.bezelsanddisplays.co.uk/ which might be of use.

There must be others out there. I just searched for "lcd bezel" using my search engine.

It was plastic project boxes I used previously, and I don't have a laser cutter.

That looks pretty good, I hadn't seen it before.

Hi @st_4489665. The simple solution I have used is to get an enclosure with a transparent lid, something like this (they are available from any of the usual sources of electronics components):

then drill holes in the lid and use machine screws to mount the display to the inside of the lid. This way I didn't need to worry about things like cutting a hole and a bezel. It provides protection for the display. The waterproof nature of the enclosure is not compromised (as long as you take measures to make a seal on the screw holes).

You do need to be careful when drilling holes in this type of plastic to avoid cracking it, but it can certainly be done and there is plenty of information on that on the Internet (I used a drill bit specifically designed for this application).