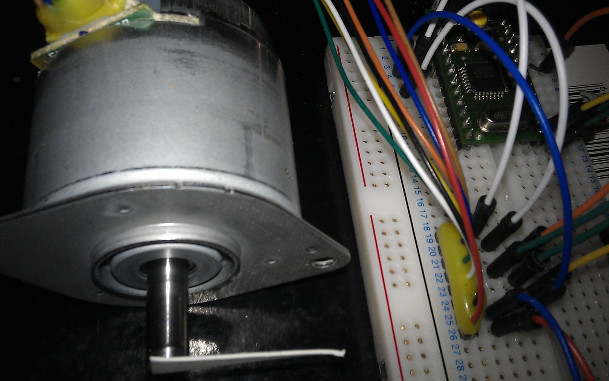

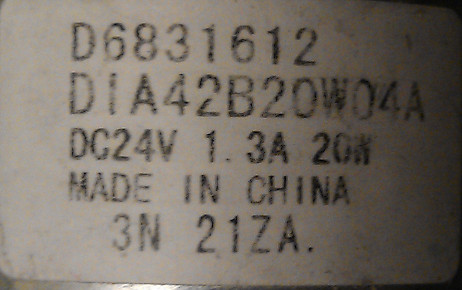

I found some rather handy little 24V BLDC motors on eBay

They do all the work for you, and provide a 400cpr incremental encoder too.

The no-load speed at 24V is 6400rpm, so at 20W they must be about 30mNm

or torque.

So I ordered on and when it arrived I sat down and implemented a Servo-loop to drive

it.

The interface is:

PWM signal (0% = full drive, 100% = no drive, note),

brake signal (active low),

direction signal.

And the quadrature encoder takes a 5V supply and gives AB outputs (no

pullups needed).

Here's my sketch:

// Arduino Sketch turning eBay BLDC motor with integral controller

// into a position-driven servo-motor

//

// eBay motor:

// http://www.ebay.co.uk/itm/DC-24V-20W-High-grade-brushless-motor-brushless-motor-with-encoder-PWM-speed-/261713199819

//

// Mark Tillotson

// 2015-03-13

//

// tested on 328p processor, encoder code needs porting to Mega...

//

// Creative Commons Attribution ShareAlike 2.5:

// http://creativecommons.org/licenses/by-sa/2.5/

//

//////////////////// pin definitions ///////////////////

// encoder pins and interrupt numbers:

#define ENC_A 2

#define ENC_B 3

#define ENC_INTA 0

#define ENC_INTB 1

// motor drive pins

#if defined(__AVR_ATmega1280__) || defined(__AVR_ATmega2560__)

# define PWM_PIN 10 // timer2 controls pin 10 on Mega

# define DIR_PIN 11

# define BRK_PIN 12

#else

# define PWM_PIN 11 // timer2 controls pin 11 on Uno etc

# define DIR_PIN 10

# define BRK_PIN 12

#endif

//////////////////// encoder ///////////////////

// [ This code assumes Uno, needs conditionalizing for Mega still ]

volatile long phase = 0 ;

volatile byte portd = (PIND & 0x0C) >> 2 ;

long read_phase ()

{

noInterrupts () ;

long result = phase ;

interrupts () ;

return result ;

}

// encoder runs at 400 counts per rev, 6000rpm+, so over 40kHz interrupt rate

// thus using direct port manipulation for quadrature decoding.

void handle_enc ()

{

byte pd = (PIND & 0x0C) >> 2 ;

pd ^= (pd >> 1) ; // convert quadrature/Gray to 2 bit binary

byte sig = (pd - portd) & 3 ; // calc difference from last sample

if (sig == 1)

phase -- ;

else if (sig == 3)

phase ++ ;

portd = pd ;

}

void enc_setup ()

{

pinMode (ENC_A, INPUT_PULLUP) ;

pinMode (ENC_B, INPUT_PULLUP) ;

attachInterrupt (ENC_INTA, handle_enc, CHANGE) ; // handle every change

attachInterrupt (ENC_INTB, handle_enc, CHANGE) ;

}

//////////////////// setup ///////////////////

void setup ()

{

TCCR2B = 0;

TCCR2B = (TCCR2B & 0xF8) | _BV(CS20); //use a 1:1 prescaler, PWM at 32kHz

analogWrite (PWM_PIN, 255) ; // low PWM means high drive on this motor

pinMode (BRK_PIN, OUTPUT) ; digitalWrite (BRK_PIN, HIGH) ; // Brake active LOW

pinMode (DIR_PIN, OUTPUT) ; digitalWrite (DIR_PIN, LOW) ;

enc_setup () ;

}

void set_drive (int level)

{

digitalWrite (BRK_PIN, level != 0) ;

digitalWrite (DIR_PIN, level < 0) ;

analogWrite (PWM_PIN, 246 - abs (level)) ;

}

//////////////////// PID loop ///////////////////

long target = 0L ;

long integ = 0L ;

long prev_ph = 0L ;

#define P 0.5 // values derived by experiment

#define I 0.001

#define D 2.5

int pid ()

{

long ph = read_phase () ;

long error = target - ph ;

float res = P * error + D * (prev_ph - ph) + I * integ ;

prev_ph = ph ;

if (abs(error) < 10)

integ += error ;

delayMicroseconds (500) ;

return (int) res ;

}

//////////////////// test code ///////////////////

int t = 0 ;

void loop ()

{

// changes target position every 1/128th time round the loop

t += 1 ;

if ((t & 0x7F) == 0)

{

int amt = (t & 0x1000) == 0 ? 1596 : 4 ;

target += amt ;

}

set_drive (constrain (pid (), -240, 240)) ; // run PID and set drive

}

Some photos:

And video: Servomotor test - YouTube

(and in slow-motion: Servomotor test - YouTube - it moves so fast its hard to tell its going 3/4 turn ![]()