I can do that jraskell.

Boards have left iteadstudio, are working their way thru customs & stuff now.

Excellent. Ordering the rest of the components from Mouser now.

wanderson:

The stencil is for applying solder paste, not tinning. It is pretty easy to solder the low pin count SMD devices, but TQFP devices are a bit harder, though not impossible. Solder paste and a stencil make the process quite a bit easier.

I use stencils and paste for my boards extensively. Just don't forget to mention that they still need to be heated somehow to temperature. I use a $30 toaster oven, though others have used hot plates as well. As for doing it by hand, take a look at the drag soldering videos on YouTube. The TQFP-44 package of the Atmel 1284P is pretty easy to drag solder. Simply position the chip, attach two corner pins with solder and then drag solder, followed by removing excess solder with solder braid. I liberally use no-clean tacky flux and using the right tip (see the videos) helps a lot also.

Lastly, despite the use of 3-mil thick mylar stencils, clean placement, etc., I find myself always inspecting the legs of the 1284P to catch bridges before they fry the chip. And if you think the 1284P is bad, try a 5mm TQFP-32 package like the USB host controller on the board that Oleg sells - 0.5mm pitch between pins. If you want to hand solder that, I suggest a microscope, a helper-device, etc. to get the placement and inspection right.

Constantin:

wanderson:

The stencil is for applying solder paste, not tinning. It is pretty easy to solder the low pin count SMD devices, but TQFP devices are a bit harder, though not impossible. Solder paste and a stencil make the process quite a bit easier.I use stencils and paste for my boards extensively. Just don't forget to mention that they still need to be heated somehow to temperature. I use a $30 toaster oven, though others have used hot plates as well. As for doing it by hand, take a look at the drag soldering videos on YouTube. The TQFP-44 package of the Atmel 1284P is pretty easy to drag solder. Simply position the chip, attach two corner pins with solder and then drag solder, followed by removing excess solder with solder braid. I liberally use no-clean tacky flux and using the right tip (see the videos) helps a lot also.

Lastly, despite the use of 3-mil thick mylar stencils, clean placement, etc., I find myself always inspecting the legs of the 1284P to catch bridges before they fry the chip. And if you think the 1284P is bad, try a 5mm TQFP-32 package like the USB host controller on the board that Oleg sells - 0.5mm pitch between pins. If you want to hand solder that, I suggest a microscope, a helper-device, etc. to get the placement and inspection right.

i really dont think i would have problems, i can hand solder ram chips without any problems, you just have to do the tinning well and then use a hot air supply to flow the chip, I have a nice reflowing station at work which makes things easier, although a good magnifying glass for inspection is crucial

spruce_m00se:

i really dont think i would have problems, i can hand solder ram chips without any problems, you just have to do the tinning well and then use a hot air supply to flow the chip, I have a nice reflowing station at work which makes things easier, although a good magnifying glass for inspection is crucial

What is the pitch between pins on a RAM chip? 0.5 or 0.65mm? I find the latter to be OK... between braid and a good pad design + flux. But 0.5mm is another creature. Do you find hot air work stations to be a good help? I have never used one but there are plenty on ebay for $65 and hundreds of dollars from established manufacturers.

I am not a qulififed solderer, but I was taught in my job,

the way i was taught it to manually takc one leg, then flux the whole chip, then hot air it,

its a good method,

tha station is incredibly useful when neccesary, although i normally only use the hot air for heatsrink tubing ![]()

check the spacing for the atmega 2560 , I would say i could do that , i dont know the spacing on the chips i have done

According to the atmel atmega 2560 datasheet you're looking at 0.5mm pitch. It's one reason I prefer the 1284p - less i/o I don't need and more spacing between chip legs. Thanks to maniacbug and others there is even great support in the arduino IDE for it.

These, http://www.schmartboard.com/index.asp?page=products_qfp&id=70, make soldering the 2560's pretty easy even with just a simple iron. Only problem is that they are not really suitable for final products. I have heard that they are able to use the same technology to produce production PC boards, but don't know what they charge.

Love the fact that they have boards that even allow hand soldering 0.4mm BGA's

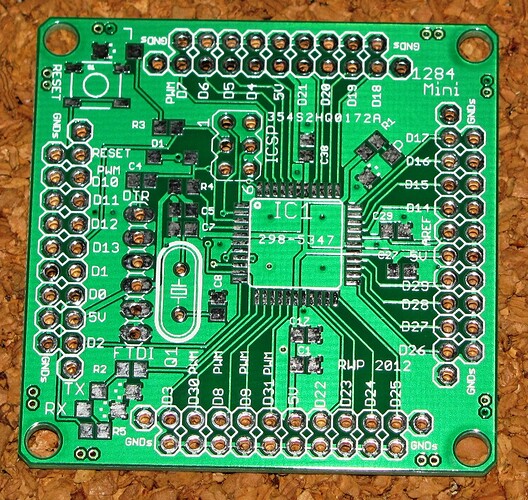

The Mini 1284's are in!

$2.50 a board mailed to your US location. $2.25 each if you want more than 1.

Paypal to cardinal flyer @ comcast . net (no spaces)

Will post this pic, PL, and schematic (all posted earlier in this thread as well) to my signature link in a few minutes.

50 boards available, get 'em while they're hot!

Robert

I have sent money for 4 boards. ![]() I have ordered enough parts to build 2 but, the boards are cheap so, I figure a couple extra won't hurt.

I have ordered enough parts to build 2 but, the boards are cheap so, I figure a couple extra won't hurt.

Thanks CrossRoads I can't wait to solder them up!

Mark

Beautiful work, Crossroads! I don't need one right now, but I wish you all the best and may be back later. Cheers!

Will have them in the mail tomorrow Mark. Thanks!

Scrounging thru all my leftover bits, I can pull enough stuff together for 1 board. 1 uC, 1 reset switch, mix of LED colors, plenty of Rs, Cs.

Ordered material for 10 boards from Mouser.

Here's what it looks with crystal and straight headers (not soldered in, just sitting there).

Payment sent for 6 boards. Already have the hardware in hand to assemble a couple. Figured I'd make sure I could actually hand assemble them before buying the hardware for all 6 boards. I've done plenty of soldering, but this will be my first time with SMD components. As a last resort, I've got some EE coworkers I'm sure I could get some assistance from. I'm already contemplating a few other SMD projects, so hoping it all goes well.

Thanks, will get those sent out in tomorrow's mail for you.

I ordered a 44 pin TQFP stencil from proto-advantage.com for the chip. Figure do that first, and then the rest of the SMTs, and certainly the thru-holes, should be solderaeble by hand without much trouble. Didn't select impossibly small parts for just that reason.

Sent a paypal for 4 this morning! Look forward to seeing the boards!

Thanks! Will send those out tomorrow as well.

pm me your paypal address.

copiertalk:

pm me your paypal address.

He has it on message #48 above.

wanderson:

copiertalk:

pm me your paypal address.He has it on message #48 above.

Thanks, I am old and blind.

Or not paying attention as usual.

Crossroads, you have paypal.