Hey guys,

Ive built a non invasive ventilator and it uses 2 pressure sensors to measure the pressure of the exit valve of the ventilator which leads to the mask. This is a project im doing for school and its due very soon and i need this to be working so any help would be appreciated.

The issue on startup the pressure sensors are calibrated, sometimes the works and the pressure sensors are zeroed but one of them sometimes does not calibrate and has random fluctuating output. This then stops my ventilator from functioning as it does not start until they are calibrated.

here is the schematic im using:

Here is my circuit diagram for the main board:

Here is the circuit diagram for the pressure sensor board which is connected to the main board via jumpers:

NOTE: I have removed the 5k and 5ohm resistors and the diodes this was a suggestion from someone on another forum

here is the code im using:

//Source code for the BIPAP/CPAP low cost device v1.0

//Arduino Nano

//Details of the hardware, connections and setup can be found in www.ub.edu/biofisica

//For code details contact jorge.otero@ub.edu / m.rodriguez@ub.edu

#include <PID_v1.h> //PID library

double Setpoint, Input, Output, flow_hp, flow_bp; //variables

double Kp=0.38, Ki=0.75, Kd=0; //variables and values for the PID controller KP(proportional),Ki(integral),Kd(derivative)

//Definitions

PID myPID(&Input, &Output, &Setpoint, Kp, Ki, Kd, DIRECT);

#define analog 10 //define digital 10 as analog.

#define analog_flow 9 //define digital 9 as analog_flow.

#include <LiquidCrystal.h> //LCD 2x16

LiquidCrystal lcd(12,11,5,4,3,2); //LCD connections

#define switchPin 6 //define digital 6 as SwitchPin.

#define SwitchMode 13 //define digital 13 as SwitchMode.

#define led 8 //define digital 8 as led.

byte autoipap = 0,lcdmodecpap=1,lcdmodebipap=1,switchState = 0,switchModestate = 0,restard; //byte variables

unsigned long t0 =micros(),tiempoahora =millis();

int Tm =10000; //Sampling frequency in microseconds

float tiempo =0;

float fc_hp=0.125; //cutoff frequency of the high-pass filter

float fc_lp=1.125; //cutoff frequency of the low-pass filter

float RC_hp =1/(2*PI*fc_hp);

float RC_lp =1/(2*PI*fc_lp);

double data_filt_hp[] = {0, 0};

double data_hp[] = {0, 0};

double data_filt_lp[] = {0, 0};

double data_lp[] = {0, 0};

double maximo=0,vmax=0,flow=0;

int pressure, epap,ipap,consigna=0;

float porcentaje,P_sensor,P_epap,P_ipap,P_sensor_abs,P_sensor2;

int ctroltime =0;

int gain_flow =100;

char P_sensorstring[4];

char P_sensorstring2[4];

char P_EPAPstring[4];

char P_IPAPstring[4];

char porcentajestring[2];

char timestring[2];

int i,z=0;

int samplepressure[25]; //buffer of 25 positions for the pressure sensor 1 readout

int samplepressure2[25]; //buffer of 25 positions for the pressure sensor 2 readout

double totalpress2 = 0.00, promediopress2 = 0.00, totalpress = 0.00, promediopress = 0.00;

double totalzero=0,totalzero2=0,samplezero,samplezero2,pressinzero,pressinzero2,zero,zero2;

#define sensorpress A0 //pressure sensor 1 output is connected to the analog input 0

#define sensorpress2 A1 //pressure sensor 2 output is connected to the analog input 1

#define analog_epap A2 //epap potentiometer adjustment is connected to the analog input 2

#define analog_ipap A3 //ipap potentiometer adjustment is connected to the analog input 3

#define analog_porcentaje A4 //cycling potentiometer adjustment is connected to the analog input 4

//Configuration

void setup() {

myPID.SetMode(AUTOMATIC); //automatic mode in PID

consigna=ipap;

Serial.begin(115200);

for(i=0; i< 24; i++) //array initialization

{

samplepressure[i] = 0;

samplepressure2[i] = 0;

}

i=0;

lcd.begin(16,2); //LCD 2x16

pinMode(switchPin,INPUT); //switchPin -> input

pinMode(SwitchMode,INPUT); //switchMode -> input

pinMode(led,OUTPUT); //led -> output

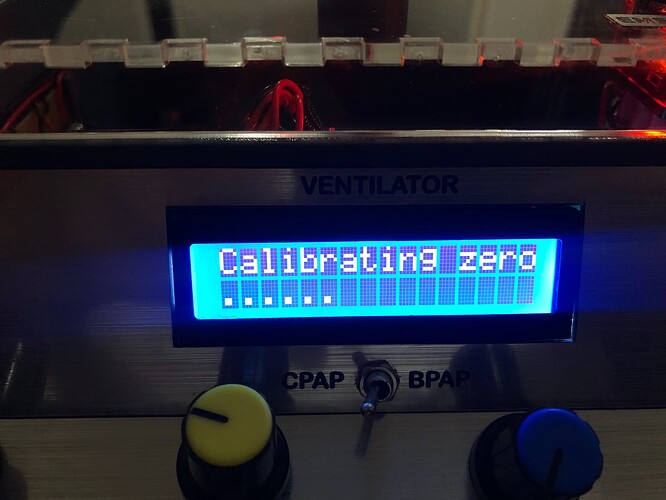

lcd.setCursor(0,0);

lcd.print("Calibrating zero");

lcd.setCursor(0,1);

for(i=0; i< 91; i++) //array initialization

{

Serial.println(i);

if (i==0 || i==6 || i==12 || i==18 || i==24 || i==30 || i==36 || i==42 || i==48 || i==54 || i==60 || i==66 || i==72 || i==78 || i==84 || i==90)

{

lcd.setCursor(i/6,1);

lcd.print(".");

}

samplezero = 2.5*analogRead(sensorpress); //zero reading for pressure sensor 1

totalzero = totalzero + samplezero;

samplezero2 = 2.5*analogRead(sensorpress2); //zero reading for pressure sensor 2

totalzero2 = totalzero2 + samplezero2;

delay(50);

}

zero=totalzero/i;

zero2=totalzero2/i;

lcd.setCursor(0,1);

lcd.print(" ");

lcd.setCursor(0,1);

lcd.print("P1:");

lcd.setCursor(8,1);

lcd.print("P2:");

lcd.setCursor(15,1);

lcd.print(" ");

for(i=0; i< 50; i++)

{

pressinzero =2.5*analogRead(sensorpress)-zero; //zero adjustment for pressure sensor 1

P_sensor=abs((pressinzero/1023)*5.0*4.8);

dtostrf(P_sensor,1,1, P_sensorstring);

pressinzero2 =2.5*analogRead(sensorpress2)-zero2; //zero adjustment for pressure sensor 2

P_sensor2=abs((pressinzero2/1023)*5.0*4.8);

dtostrf(P_sensor2,1,1, P_sensorstring2);

lcd.setCursor(4,1);

lcd.print(P_sensorstring);

lcd.setCursor(12,1);

lcd.print(P_sensorstring2);

delay(30);

if (P_sensor >0.3 ||P_sensor2>0.3)

{

lcd.setCursor(0,0);

lcd.print("err calibrating ");

lcd.setCursor(0,1);

lcd.print(" ");

lcd.setCursor(4,1);

lcd.print(P_sensorstring);

lcd.setCursor(12,1);

lcd.print(P_sensorstring2);

lcd.setCursor(0,1);

delay(2000);

lcd.print("Restart sofware.");

delay(1000);

restard =1;

i=50;

}

}

i=0;

}

// Main program loop

void loop() {

if (restard ==1)

{

i=0;

totalzero=0;

totalzero2=0;

restard=0;

setup();

}

samplepressure[i] = 2.5*analogRead(sensorpress); //Pressure sensor 1 sampling

totalpress = totalpress + samplepressure[i];

samplepressure2[i] = 2.5*analogRead(sensorpress2); //Pressure sensor 2 sampling

totalpress2 = totalpress2 + samplepressure2[i];

ctroltime = 5;

i++;

if (micros()-(t0)>=Tm)

{

tiempo=(micros()-t0);

t0=micros();

promediopress = (totalpress/i); //pressure average for sensor 1

promediopress2 = (totalpress2/i); //pressure average for sensor 1

pressinzero = promediopress-zero; // zero adjustment for pressure sensor 1 - sensor should be let with no pressure and the zero adjusted with the potentiometer

pressinzero2 = promediopress2-zero2; // zero adjustment for pressure sensor 2 - sensor should be let with no pressure and the zero adjusted with the potentiometer

P_sensor=(pressinzero2/1023)*5.0*4.8; //conversion to pressure in cmH2O units.

P_sensor_abs = abs(P_sensor);

Serial.println(P_sensor_abs);

epap=0.833*analogRead(analog_epap)+170; //epap range from 4 cmH2O to 24 cmH2O (170-1023)

ipap= 0.833*analogRead(analog_ipap)+170; //ipap range from 4 cmH2O to 24 cmH2O (170-1023)

if (epap>ipap)

{

epap=ipap; //epap value never can be higher than ipap value

}

P_epap =(epap/1023.00)*5.0*4.8; //conversion of epap pressure to cmH2O units

P_ipap =(ipap/1023.00)*5.0*4.8; //conversion of ipap pressure to cmH2O units

porcentaje=100*(analogRead(analog_porcentaje)/1023.00); //conversion of the cycling value to percentage (0% - 100%)

flow=gain_flow*(pressinzero2-pressinzero); // flow calculation from the pressure difference in the sensors

if (flow>0)

{

flow=100*sqrt(flow); //flow+ linearization

}

else

{

flow=-100*sqrt(-flow); //flow- linearization

}

int flow_out = map(flow,-20000,40000,0,255); // rescaling flow values (0-255) for PWM control in pin 9

analogWrite(analog_flow,flow_out);

Input =pressinzero2; //pressure of the transducer is the input for the PID controller

Setpoint= consigna; //setpoint for the PID controller

myPID.Compute(); //myPID function call

if (pressinzero2 < 250)

{

Output=85; //if pressure is very low it is because there is no patient, so output is settled very low

}

analogWrite(analog,Output); //analog output 10 actuates the blower

switchState = digitalRead(switchPin); //adjust values switch readout

switchModestate = digitalRead(SwitchMode); //CPAP/BIPAP modes switch readout

if (switchModestate == LOW && switchState == LOW) //CPAP mode is active when both switches are off

{

if (lcdmodecpap ==1)

{

myPID.SetTunings(Kp=0.12, Ki=0.75, Kd=0); //PID values for CPAP mode

lcd.setCursor(0,0);

lcd.print(" CPAPmode ");

lcd.setCursor(0,1);

lcd.print("Press ");

lcd.setCursor(11,1);

lcd.print("CmH20");

lcdmodecpap = 0; // no rewritting of the display until mode is switched again

}

digitalWrite(led , LOW);

lcd.setCursor(7,1);

dtostrf(P_sensor_abs,2,0, P_sensorstring);

lcd.print(String(P_sensorstring));

consigna=ipap; //setpoint is adjusted by the ipap potentiometer

lcdmodebipap=1; //allows switching to BIPAP mode

}

if (switchModestate == LOW && switchState == HIGH) //CPAP mode, adjustment of the parameters

{

lcd.setCursor(0,0);

lcd.print(" Set CPAP ");

lcd.setCursor(0,1);

dtostrf(P_ipap,2,1, P_IPAPstring);

lcd.print(String("IPAP " )+String(P_IPAPstring)+String(" CmH2O ")); //display the IPAP value

lcdmodebipap=1; //allows mode switching

lcdmodecpap=1; //allows mode switching

}

if ( switchModestate == HIGH && switchState == LOW) //BIPAP mode is active, no parameters setup

{

if (lcdmodebipap ==1)

{

lcd.setCursor(0,0);

lcd.print("BiPAPmode ");

lcd.setCursor(12,0);

lcd.print("%");

lcd.setCursor(0,1);

lcd.print("Press ");

lcd.setCursor(11,1);

lcd.print("CmH20");

lcdmodebipap=0; // LCD is just written once

}

dtostrf(porcentaje,2,0,porcentajestring); //conversion of % to string

lcd.setCursor(10,0);

lcd.print(String(porcentajestring));

lcd.setCursor(7,1);

dtostrf(P_sensor_abs,2,0, P_sensorstring); //conversion of pressure to string

lcd.print(String(P_sensorstring));

Serial.println(P_sensorstring);

if (autoipap==0)

{

lcd.setCursor(13,0);

dtostrf(ctroltime,1,0,timestring); //conversion of time to string

lcd.print(String(" -")+String(timestring));

}

lcdmodecpap=1; //allows mode switching

}

if (switchModestate == HIGH && switchState == HIGH) //BIPAP mode, parameter adjustment

{

lcd.setCursor(0,0);

dtostrf(P_ipap,2,1, P_IPAPstring);

lcd.print(String("IPAP ")+String(P_IPAPstring)+String(" CmH2O "));

lcd.setCursor(0,1);

dtostrf(P_epap,2,1, P_EPAPstring);

lcd.print(String("EPAP ")+String(P_EPAPstring)+String(" CmH2O "));

lcdmodebipap=1;

lcdmodecpap=1;

}

flow_hp = mifiltroHP(flow,tiempo/1000000,RC_hp); //high-pass filtering flow signal

flow_bp = mifiltroLP(flow_hp,tiempo/1000000,RC_lp); //low-pass filtering flow signal

if (flow_bp>350 && switchModestate == HIGH && switchState == LOW) //detection of inspiratory flow > 350 when BIPAP mode is active

{

myPID.SetTunings(Kp=0.1, Ki=0.45, Kd=0); //new PID parameters

digitalWrite(led , HIGH); //inspiration detection LED is active

tiempoahora=millis();

maximo = max(maximo, flow_bp); //maximum flow calculated

if (maximo>1.05*flow_bp)

{ //detects a 5% flow reduction respect to the peak flow

vmax =porcentaje/100*maximo; //calculation of the change point to EPAP (Vmax)

if (flow_bp<vmax)

{

consigna = epap; //if the flow is lower than the change point, switches to EPAP mode

}

myPID.SetTunings(Kp=0.65, Ki=0.2, Kd=0); //new PID parameters

}

else

{

consigna=ipap; //if the flow is inspiratory but not 5% reduced, it maintains IPAP mode

}

}

if (flow_bp<350 && switchModestate == HIGH && switchState == LOW) //detect flow < 350 in BIPAP mode

{

digitalWrite(led , LOW); //switch off inspiration led (flow<350 = expiration)

if (millis()>(tiempoahora+(1000*ctroltime))&& millis() <= (tiempoahora+(1000*ctroltime)+1010)) //detects if the flow<350 time is greater than control time

{

autoipap=1; //autoIPAP mode activated

consigna=ipap; //IPAP mode activated

lcd.setCursor(14,0);

lcd.print(String(F("ON")));

if (millis()> tiempoahora+(1000*ctroltime)+1000)

{

consigna=epap;

lcd.print(String(timestring));

}

}

else

{ //no autoIPAP mode needed

consigna=epap;

autoipap=0;

}

if (millis()> tiempoahora+(1000*ctroltime)+3000)

{

tiempoahora=millis(); //time variable reset

}

maximo=0; //maximum varibles reset

vmax=0;

}

if (switchModestate == LOW && switchState == LOW) //CPAP mode active, maintains IPAP

{

consigna=ipap;

}

if (switchModestate == LOW && switchState == HIGH) //CPAP mode active, setting parameters, maintains IPAP

{

consigna=ipap;

}

//variables reset

promediopress=0;

totalpress=0;

promediopress2=0;

totalpress2=0;

i=0;

}

} //end of main program loop

double mifiltroHP(double dato,double dt,double RC) //high-pass filtering of flow function

{

double alpha = RC/(RC+dt);

data_hp[1] = dato;

// High Pass Filter

data_filt_hp[1] = alpha * (data_filt_hp[0] + data_hp[1] - data_hp[0]);

// Store the previous data in correct index

data_hp[0] = data_hp[1];

data_filt_hp[0] = data_filt_hp[1];

return (data_filt_hp[1]);

}

double mifiltroLP(double dato,double dt,double RC) //low-pass filtering of flow function

{

double alpha = dt/(RC+dt);

data_lp[1] = dato;

// low Pass Filter

data_filt_lp[1] = alpha *data_lp[1]+(data_filt_lp[0]*(1-alpha));

// Store the previous data in correct index

data_lp[0] = data_lp[1];

data_filt_lp[0] = data_filt_lp[1];

return (data_filt_lp[1]);

}

Here is what i see on my LCD when it doesnt seem to want to calibrate:

I ran this code to test the output of the A1 pressure sensor the one that seems to give a fluctuating value at times:

int Rawval; // ADC value

int Pressoffset = 102; // ADC value @ 0 pressure

int adcMax = 921; // ADC value @ 5kPa (51 cmH2O)

int span;

int Newval;

void setup()

{

Serial.begin(9600);

}

void loop()

{

span = adcMax - Pressoffset; // 819 here

Rawval = analogRead(A0);

Serial.print(" Rawval = \t");

Serial.print(Rawval);

Newval = Rawval - Pressoffset;

Serial.print("\t Pressure = \t");

float pressureVal = (float)Newval * 51.0 / (float)span;

Serial.print(pressureVal, 1); // cmH2O

Serial.println(" cmH2O");

delay(2000);

}

Here are the results: