Are you referring to something like?

My Soldering Tweezers Broke

![]()

My favorite tweezers broke a few months back.

Amazon had these inexpensive pimple tweezers on sale so I purchased a couple.

About $5.00 each.

These are 403 stainless steel (slightly magnetic), couldn't find 304.

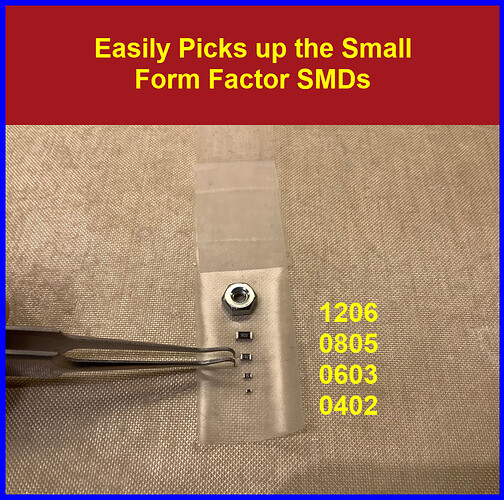

Been using these for a while and they are doing the job quite nicely.

The bend is 90 degrees to the work surface so they are ideal to manipulating SMDs while hand soldering or component placement.

These will probably be my go to source for tweezers for fine work jobs.

Blind Mounting Screws for PCB Stand-Offs

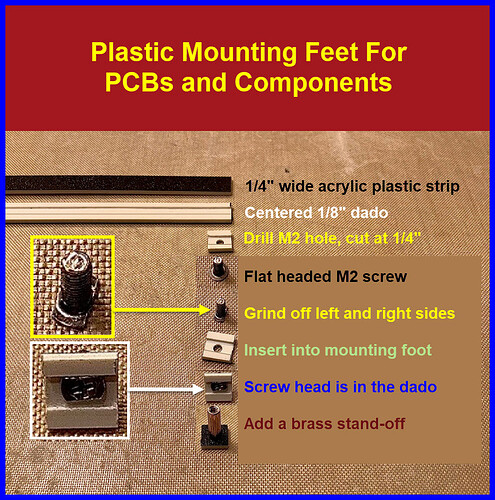

The following describes a simple method for making effective low profile mounting feet for PCBs.

______________________________________________________________________________________________________

Mounting feet.

- 1/4” wide acrylic plastic strips are made with a CNC machine or a router.

- A centered 1/8” dado is made down the length of the 1/4” strips.

- These strips are .064” thick with the dado set to .032”

- Drill centered (on the dado) M2 holes every 1/4” down the length above strips.

- Cut the feet with a razor saw every 1/4".

______________________________________________________________________________________________________

Screws

- Grind the left and right sides off flat headed M2 screws.

- Insert the modified screws through a mounting foot from above.

- Add a brass M2 stand-off to this screw.

______________________________________________________________________________________________________

PCB Mounting

- Attach 4 mounting feet from above in the PCB mounting holes.

- Position this assembly on your plastic chassis surface.

- Use DCM (Methylene chloride) or Epoxy to affix the 4 feet to the chassis.

[snipped the rest]

I think I found the seller. Did the seller have 3 options, single curved or single straight for $5 each, and 3 pack for $8? I need a new one as well, I dropped my favorite tweezer and it landed in a funny way, the tip ended up split out like Rhett Butler's mustache. When I tried to straighten it, I ended up with 2 tiny pieces and a blunted tweezer. It was from a $20 multi tweezers kit, the other are much wider and I would have a hard time getting tiny SMD parts positioned well.

Amazon.com has a good selection.

Adding a Clear Acrylic Bezel to a Project Box

The following images discuss the process for adding a display bezel to a project box/enclosure.

The discussion assumes you have access to some tools.

We are adding a SSD1306 OLED display to the cover of a Project Box.

We use double stick tape to affix a laminated label to the surface of the box cover.

There is a cutout in this label for viewing the display.

This cutout is smaller than the bezel we are discussing.

Fantastic!

So i take it you're an Iron Maiden fan and hallowed32 be thy name !

![]()

Hi from France ![]()

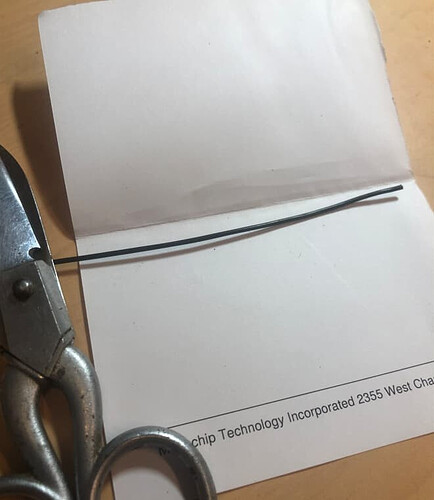

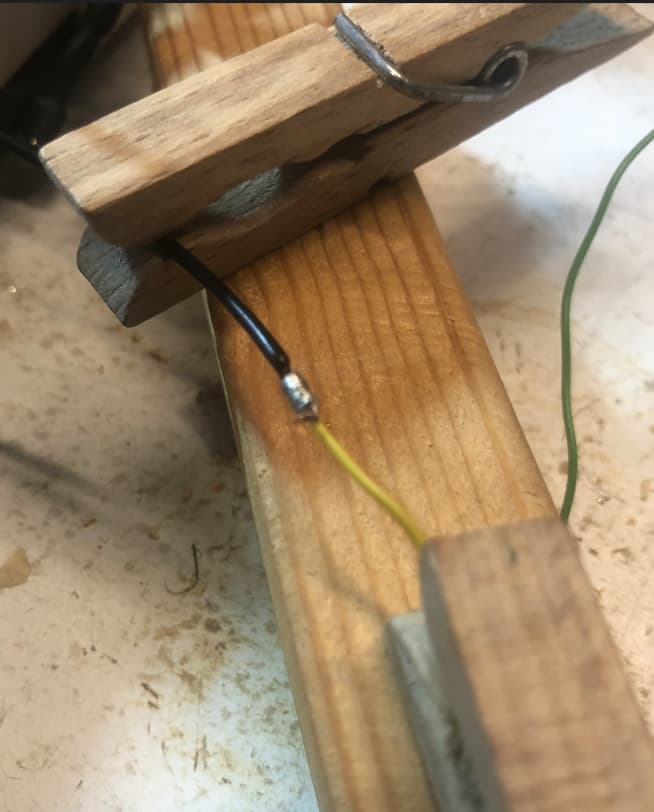

How to cut series of wires or heat-shrink to an identical length. The tool is simple and free, and can be adapted to any situation!

Hi to France! ![]()

Sorry I don't get it, can you elaborate?

Fold the paper at the crease around the wire with the end of the wire flush with the edge.

The cut the wire at the other end flush with the other edge.

Wire will be as long as the folded crease.

Tom... ![]()

![]()

![]()

![]()

Thanks, that's really useful, my OCD approves!

Tom explained how to use it ![]()

You don't have to use an old Microchip packing list for it to work!

I had seen the post, that's why I proposed my solution.

LOL, I was so dumb....I thought the was an actual video there, until nothing happened after several clicks. ![]()

![]()

8 posts were split to a new topic: Code folding in the IDE