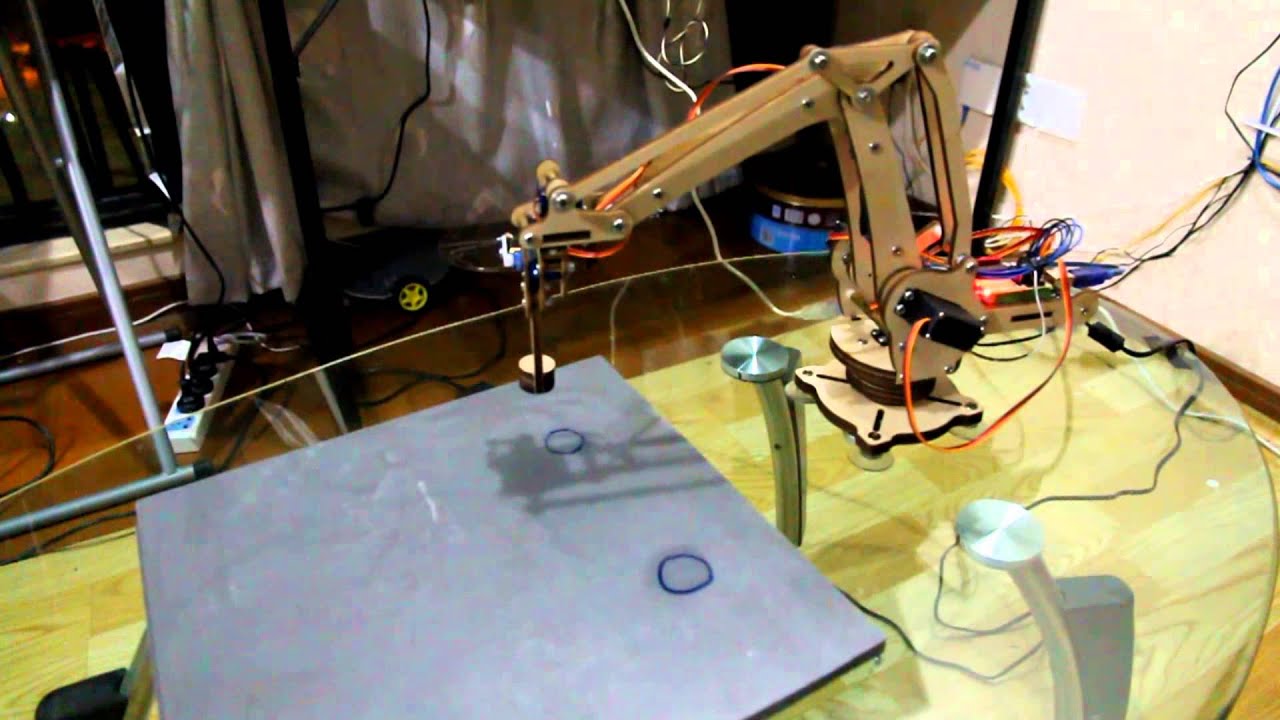

PDF patterns would allow dimensionally accurate patterns to be printed, then traced onto what ever the construction material is. A long time back I started making an arm out of craft sticks which are light and fairly strong when doubled up and braced. The important part is getting accurate dimensions of the parts, the holes and the pivot points used in the arm. Below is an arm of somewhat similar design.

Here, the Karvinens use an alumin(i)um / polyethelene composite called Dibond. I'm going to try get some offcuts somewhere...

I'm assuming / hoping the screws, nuts, spacers and so on are all standard (hopefully Metric ![]() )sizes.

)sizes.

Hi!

That's and awesome work.

I have 3D printer, if you want i can try to print it with ABS. That would give an easy solution for making the arm.

Thanks and best regards

zoomkat:

Would be nice to publish the arm frame plans in a pdf format which could be printed out on standard printer paper (larger parts might have to be split between two sheets of paper). I like the wood arm frame as wood can be easily worked with simple tools. 2'x2' sheets of 5.2mm lauan plywood are available at the US home improvement stores for ~$3.

Yes, our goal is to make a cheap and easy build robot arm. I have sent you a message about the pdf file.

malopezn:

Hi!That's and awesome work.

I have 3D printer, if you want i can try to print it with ABS. That would give an easy solution for making the arm.

Thanks and best regards

Hi malopezn,

The 3D print one may be a cool idea of building this robot arm. But it may take a lot of time by making the parts by the 3D printer. While using laser cutting, it may be faster and easier.

Thanks so much.

Best Regards,

Eric

The second version of the robot arm is quite stable now. Here is a stacking test by using the gripper. More applications and test videos will be updated soon.

See the video here:

A Vacuum Gripper Suction Cup is often used on industry robot arm in manufacture. And we also add a small one on uArm.

The Vacuum Gripper Suction Cup is controlled by a small Vacuum Pump and a Solenoid Valve.

We made the first load test of the robot arm by using the Vacuum Gripper Suction Cup. It can lift a 330ml Coca Cola and move it to another place. More applications and test videos with the Vacuum Gripper Suction Cup will be updated soon.

See the video here:

After several tests of the arm with vacuum gripper suction cup, the robot arm can work very well.

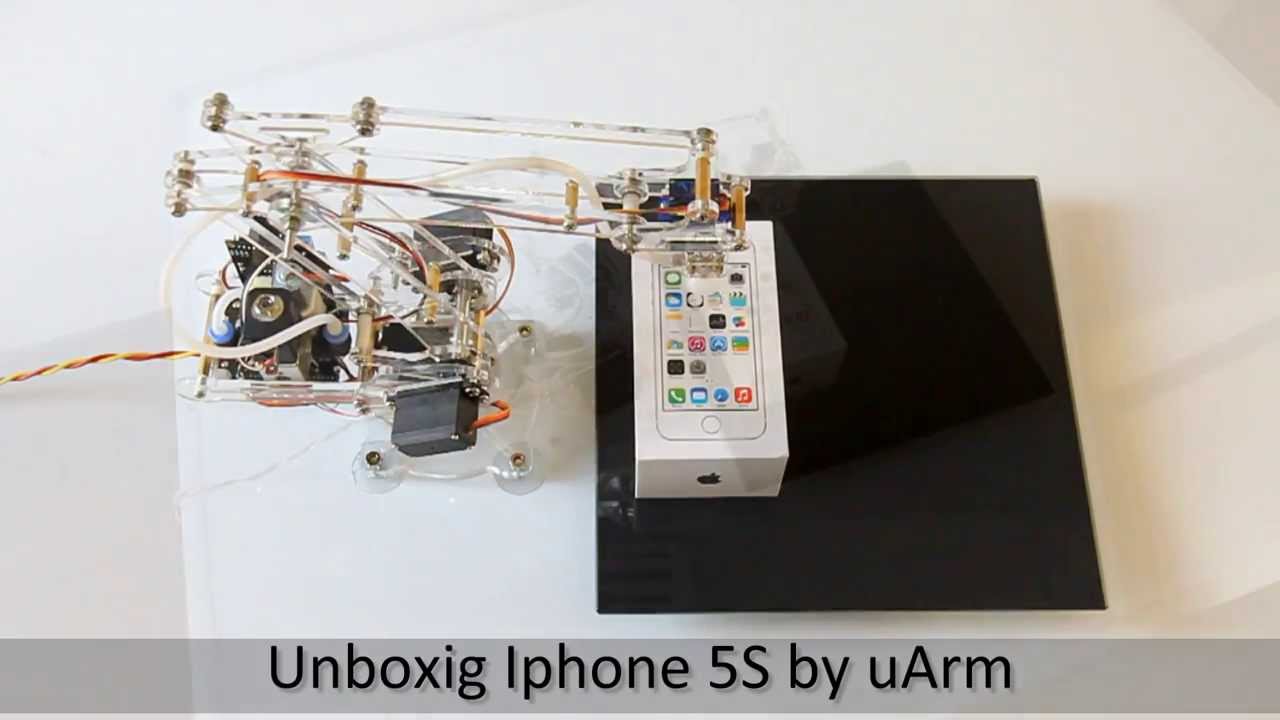

Recently, we got an Iphone 5S, so we decide to make an unboxing test of Iphnoe 5S by uArm.

Let’s see how it works.

More interesting applications and test video of uArm will be updated soon.

Hi everybody!

First of all I want to congratulate you for this project, it´s a really cool arm, the movements are very smooth.

I´m doing something like that for my graduate project, is an aluminum arm and I'm trying to make the kinematic control. I have simulated the movement of all axes with 5 order polynomics, but I have not yet tested physically.

Can you share your code? it´s really interesting how the arm work.

Thanks!

Hi vulture156,

Of course we can share the Arduino source code to you. You can send an email to us at: ufactory.info@gmail.com to ask for the code.

Best Regards,

Eric

Stunning work, guys.

I hope my local laser cutting guys that I approached get back to me soon... If not, I'll look further afield. Those guys are like 15 minutes drive away....

In the past if one of the below mini vacuums would be strong enough to be used with a suction cup on a small arm.

JimboZA:

I hope my local laser cutting guys that I approached get back to me soon... If not, I'll look further afield.

Turns out Mrs Jimbo deals with one of these outfits- so that's an alternative.

JimboZA:

JimboZA:

I hope my local laser cutting guys that I approached get back to me soon... If not, I'll look further afield.Turns out Mrs Jimbo deals with one of these outfits- so that's an alternative.

Hope to see your update of your own arm.

zoomkat:

In the past if one of the below mini vacuums would be strong enough to be used with a suction cup on a small arm.

Sound a good idea.

We have got some new servos for uArm.

Ordering my laser cut parts today.

Guys can you post a close-up of the brass stud and rivets that you mentioned in the parts list you sent me?

Also, the long spacers between the sides- see pic attached- are they on the parts list? I don't know what they are called. They look similar to the spacers I got with my Magician chassis.... are they commercial parts? EDIT... is that what you're calling Brass Studs, items 8-11 on the list?

I think you mentioned an assembly instructable somewhere.... is that up?

JimboZA:

Ordering my laser cut parts today.Guys can you post a close-up of the brass stud and rivets that you mentioned in the parts list you sent me?

Also, the long spacers between the sides- see pic attached- are they on the parts list? I don't know what they are called. They look similar to the spacers I got with my Magician chassis.... are they commercial parts? EDIT... is that what you're calling Brass Studs, items 8-11 on the list?

I think you mentioned an assembly instructable somewhere.... is that up?

Hi Jim,

Here is all the screws, nuts, bearings and brass stand-offs for assembling.

The long spacers you mentioned are the brass stand-offs, as we call Brass Studs. So sorry about my poor English. Is brass stand-offs right?